65/232

Building Technologies

Boiler sequence controller RMK770

CE1P3132en

HVAC Products

5 General functions, fundamentals

23.04.2009

T

T

31

31

B

1

7

T

T

T

T

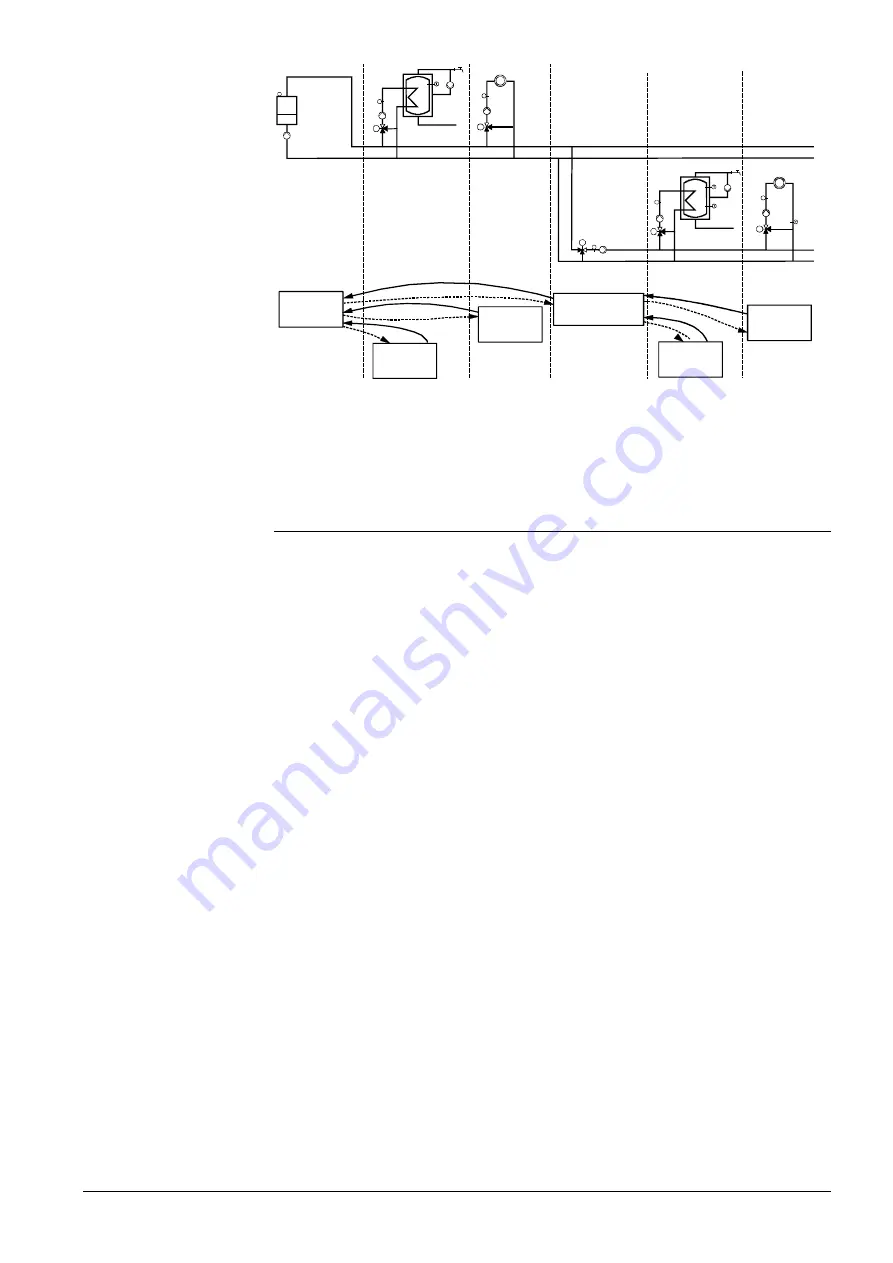

Heat

source

Heat

consumer

Heat

consumer

Heat

consumer

Heat

consumer

Heat consumer /

primary controller

The heat demand signals can be assigned a priority.

If, for example, DHW heating is operated with absolute priority, its heat demand signal

must be given priority. This temperature request is therefore the decisive variable.

With DHW heating, it can also be parameterized whether – during DHW heating – the

heat demand shall be evaluated as a maximum value or in the normal way.

5.6.2 Load

control

Load control enables heat generation to reduce the amount of heat drawn by the heat

consumers (load reduction via locking signals), or to increase it (load increase via

forced signals).

In the case of load control via locking signals, a differentiation is made between critical

and uncritical locking signals.

In the case of forced signals also, a distinction is made between critical and uncritical

signals.

These differentiations allow the heat consumers to respond to load control in different

ways.

Examples where a load reduction can be triggered are the following:

•

Protective boiler startup (the boiler temperature is still below the minimum boiler

temperature):

−

Load reduction via critical locking signals

•

Maintained boiler return temperature without separate mixing valve (acting on the

heating circuits):

−

Load reduction via critical and uncritical locking signals

•

Shifting DHW priority (if the boiler temperature setpoint is not reached during DHW

heating, the amount of heat drawn by the heating circuits is restricted):

−

Load reduction via uncritical locking signals

•

Absolute DHW priority (DHW heating is given priority over the heating circuits; the

heating circuits may not draw any heat:

−

Load reduction via uncritical locking signals

In many cases, the kind of locking signals to be generated can be parameterized.

Examples where an increase in load is demanded are the following:

•

Overtemperature protection (pump overrun, mixing valve overrun)

•

Use of residual heat in the case of solid fuel boilers (not with the RMK770!)

•

Load management in district heat networks (not with the RMK770!)

In the case of pump / mixing valve overrun, the heat consumers are requested to draw

heat at the same level for a certain period of time (overrun time) although they require

Example 2: Heat source,

primary controller and

heat consumer

Examples of load

reduction

Examples of load

increases