76/232

Building Technologies

Boiler Sequence Controller RMK770

CE1P3132en

HVAC Products

6 Boiler sequence management

23.04.2009

T

T

T

TMnRt

TMnFl

T

1

2

m

2

.

m

1

31

32

S

58

T

T

T

TMnRt

TMnFl

T

1

2

m

2

.

m

1

313

2S

5

9

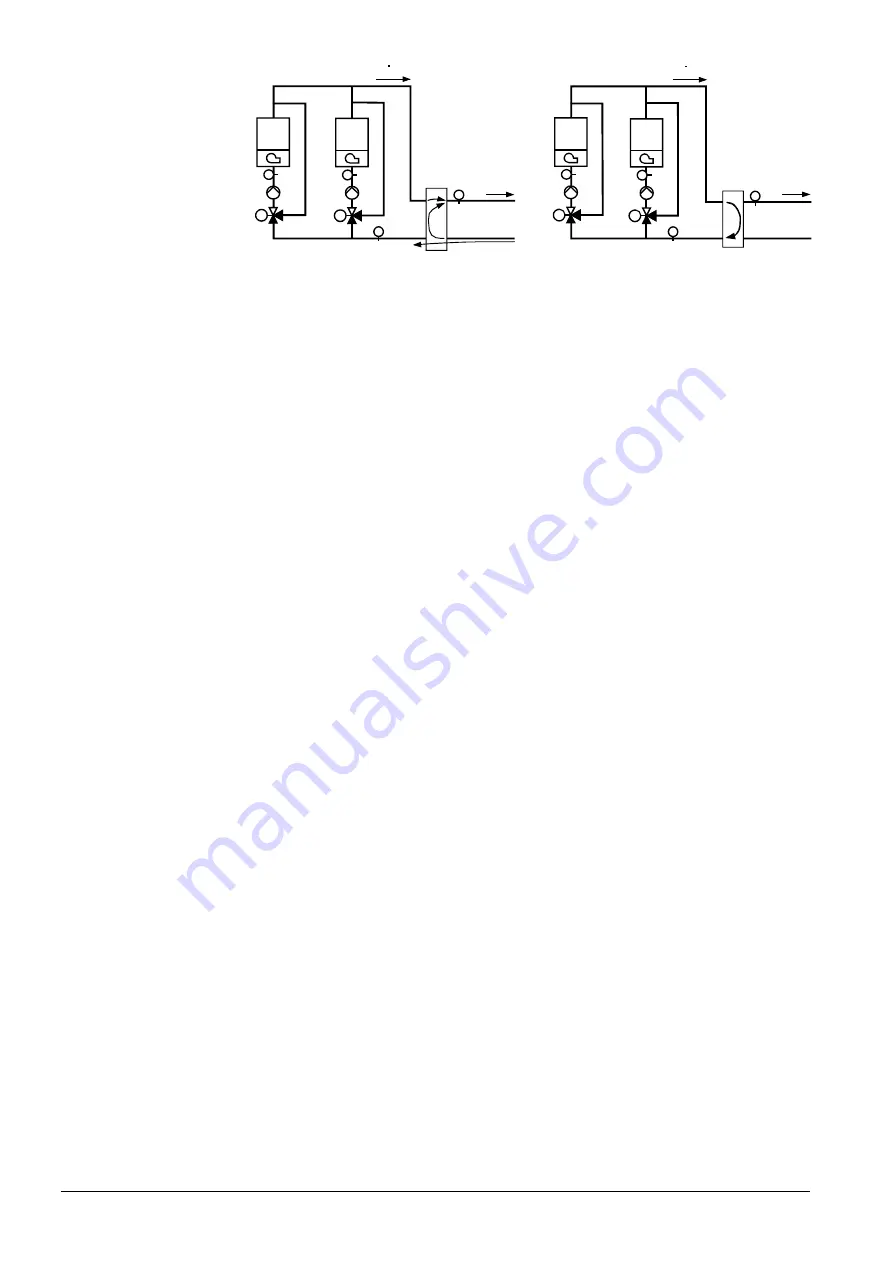

Startup and part load operation (m

1

< m

2

)

Setback operation (m

2

= 0)

Usually, the main flow temperature TMnFl is a mixture of heating circuit return tempera-

ture and boiler temperature. The level of mixing depends on the water volumes on the

boiler and consumer side.

If no more water can circulate on the consumer side, it can well be that the temperature

acquired by the return temperature sensor TMnRt is higher than the main flow tempera-

ture TMnFl since there is no circulation at that sensor. To ensure that in such cases

there is no demand for unnecessarily high boiler temperatures, it is practical to use the

main return temperature as an additional controlled variable. The controller makes

automatically a maximum selection of the 2 sensors.

With plant types K1.x, K2.x and K3.x, a main pump is preconfigured since these plant

types do not have their own boiler pump. Basically, a main pump can be configured for

each plant type (

… > Outputs… > Main pump

). If, in addition, main pump B is configured,

the main pump is automatically set as a twin pump.

The main pump always operates when there is demand for heat.

If sustained mode is required for the boiler sequence,

… > Settings > Boiler sequence

manager > Sustained mode

can be used to parameterize whether the main pump shall also

operate in sustained mode.

For types of plant without individual maintained boiler return temperature, a common

maintained boiler return temperature can be delivered. This is activated by assigning a

terminal (

… > Outputs > Maint boiler return temp 3-pos

or

Maint boiler return temp mod

). In

addition, a return sensor for the maintained boiler return temperature must be config-

ured (

…> Inputs > MBRT return sensor

).

If a frost protection function is required due to the return on the consumer side, a

separate return sensor must be configured on the consumer side (

… > Inputs… Consumer

return sensor

).

In addition to fault supervision of the main pump and supervision of the main flow

temperature sensor, 3 binary fault inputs are provided for fault supervision of the boiler

sequence. These are freely configurable.

Heat requests from other devices can be accepted via bus. In addition, 3 binary inputs

and 1 analog input are available for indicating heat requests.

Main flow and main return

temperature sensor

Main pump

Common maintained

boiler return temperature

Return sensor on the

consumer side

Fault supervision

Heat request