Installation:

• Remove the front cover.

• Mount the starter on a vertical wall/ plate free from

vibrations with proper nuts and bolts. Refer Fig. 8 for

mounting dimensions and Fig. 4 for permissible mounting

position.

• Remove the rubber grommets for the incoming and

outgoing cable connections.

• Connect incoming and outgoing cables as follows (Refer

Fig. 2 & 3):

– Use proper cable glands to ensure dust proofing. For

conduit entry use packed washers.

– Select correct size of cables from Table-A

– Connect line and motor leads exactly as per wiring

diagram pasted inside the cover of the starter.

– Terminate the incoming cable on terminal block.

Automatic Star Delta

Starter 3TE7291-0A

For dependable service, it is of utmost

importance that instructions given below are

followed for selection, inspection, installation,

commissioning, operation and maintenance.

s

ASD-11 Starter (Self reset)

Selection of Starter

• Refer Table A for recommended selection of 3TE72

starters.

Table A: kW/HP Rating, thermal overload relay range &

fuse rating, Coil Voltage, Maximum full load current for

different types of motors.

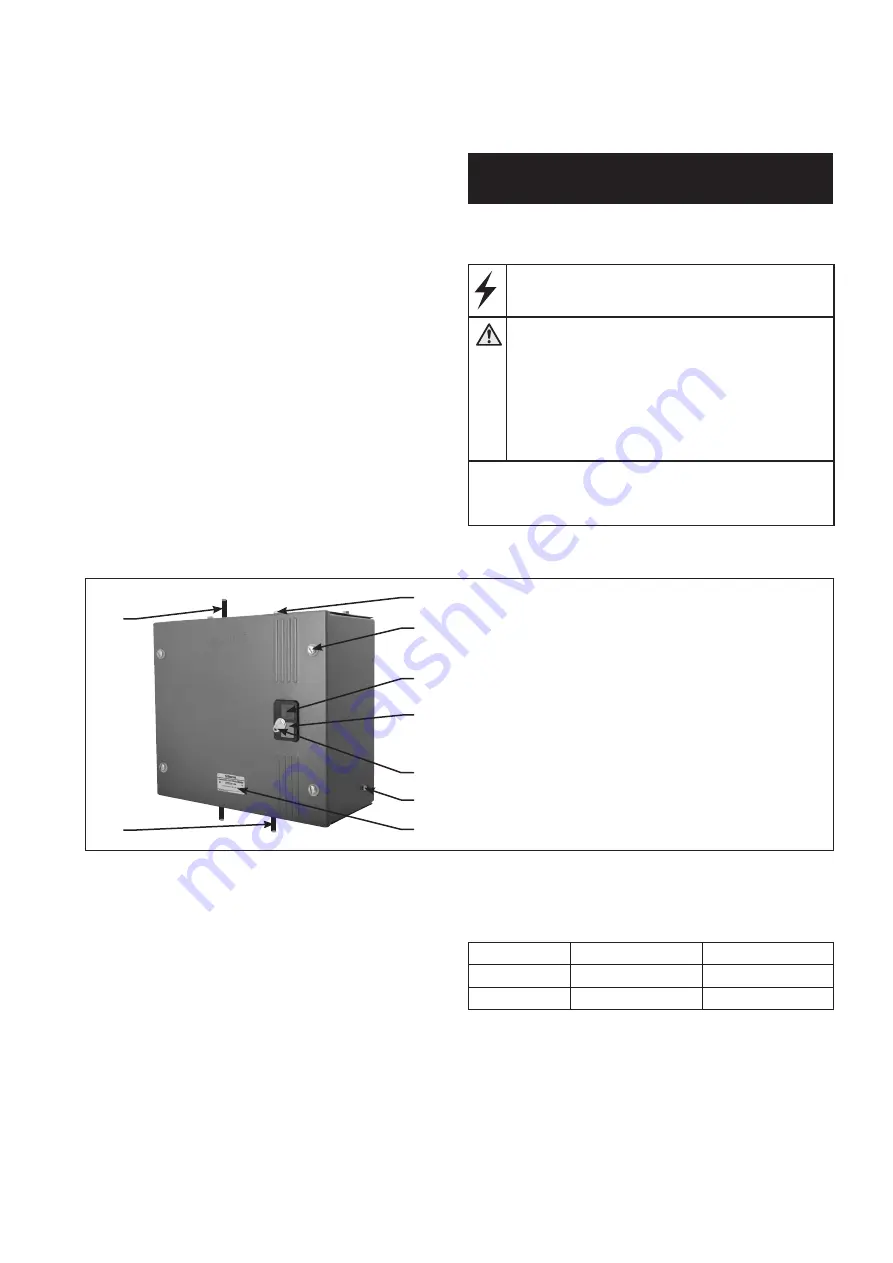

1. ON Push Button

2. OFF Push Button

3. Earthing Screws

4. Rubber Grommet (Not visible in Fig 1.)

5. Name Plate

6. Incoming Cable

7. Outgoing Cable

8. Cover Fixing Screws

9. Mechanical Latch (OFF push button) to be used for

preventing undesired ON operation of Starter

Fig. 1: ASD-11 Starter

– Connect outgoing cables on the Relay (K1) terminals

and Delta contactor (Q3) terminals.

Tightening torque (N-cm):

kW Ratings

Incoming Terminals

Outgoing Terminals

7.5 – 11

80 – 140

80 – 140

15 – 18.5

150 – 210

100 – 150

• Connect the earthing conductor to terminals marked

(earth) on the starter body with torque 80 to 140 N-cm.

The Starter is now ready for commissioning.

• Initially set the overload relay to 0.58 times the rated

motor current.

• Set the timer dial to the nearest value of starting time

available on motor name plate

• If it is not available then set the dial to approximately

6-8 secs.

Installation, Operation & Maintenance

Instructions

Please read and understand these instructions before

installating, operating, or maintaining the equipment. Keep for

future reference

Danger

Hazardous voltage can cause death or serious injury. Disconnect

power before working on equipment.

Warning

Automatic Motor Restart.

Can cause death, serious injury or property damage.

Do not use automatic reset mode when unexpected automatic

restart of the motor can cause injury to persons or damage to

equipment.

Reliable functioning of the equipment is only ensured with

certified components. Commissioning and maintenance by

qualified personnel only.

NOTICE

This product has been designed for environment A. Use of this product

in environment B may cause unwanted electromagnetic disturbances in

which case the user may require to take adequate mitigation measures.

IS/IEC 60947-4-1

6

7

4

8

1

9

3

2

5

Summary of Contents for TE7291-0A Series

Page 5: ...Notes ...