Technical Instructions

Document Number 155-067P25

October 28, 2010

Page 12

Siemens Industry, Inc.

Chassis Tube

Connector and

Restrictor Plate

Replacement

1. Remove thermostat chassis from wall. Terminal does not have a ball check valve.

NOTE:

You must close off the supply air. For example, use a connector with the supply air

terminal plugged.

2. Remove two Phillips head screws from connector on back of thermostat chassis. Pull

connector out of recess. If necessary, pry connector loose with a screw driver, but be

careful not to damage restrictor plate and gasket.

3. Remove gasket from under connector. Remove restrictor. Remove second gasket from

under restrictor.

4. Use restrictor replacement kit 192-321 to replace gasket, restrictor, and second gasket.

NOTE:

The restrictor plate is keyed to ensure proper orientation during installation.

5. Remove filters from existing connector and insert in new connector. Or, if filters are dirty,

use restrictor replacement kit 192-321 to replace filters.

6. Use chassis tube connector replacement kit 192-525 to replace connector and mounting

screws.

Service Parts

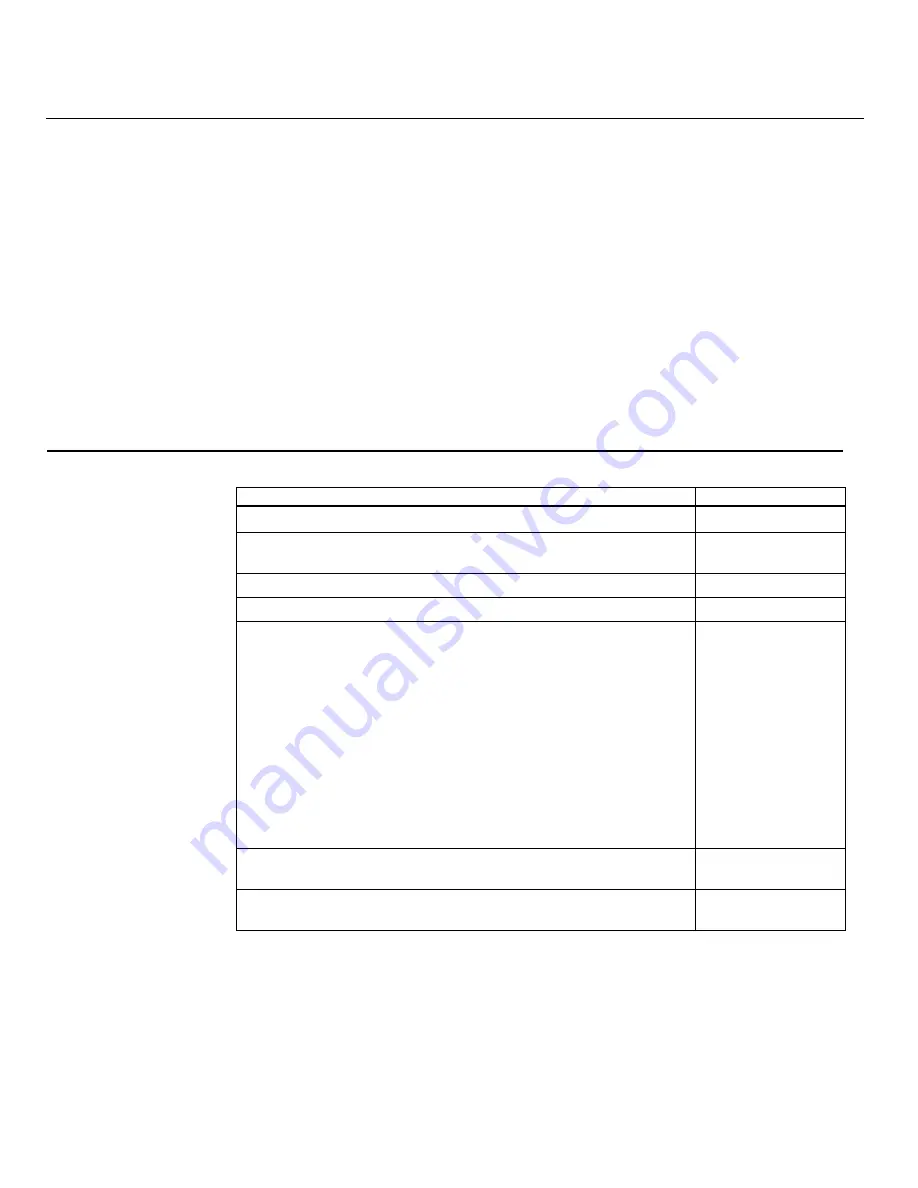

The following chart lists accessory parts and tools available for thermostat service.

Description Part

Number

Dial thermometer (-40 to 140

°

F, -40 to 60

°

C) with pocket case

141-0573

Basic pneumatic calibration kit with thermometer, gauge, squeeze

bulb, fittings, and case

832-177

Test head kit

832-179

Calibration tools

832-178

Test probe to check pressure with cover on

Needle probe with 1-1/2” diameter gauge 0-30 psig

(0-200 kPa) and calibration/cover wrench

192-633

Needle probe, no gauge (package of five)

192-759

1-1/2” diameter gauge , 0-200 kPa,

back connected 1/8” NPT male

142-0344

1-1/2” diameter compound gauge, 0-30 psig/0-200 kPa,

back connected 1/8” NPT male

142-0373

1-1/2” diameter compound gauge, 0-30 psig/0-200 kPa,

bottom connected 1/8” NPT male.

Replacement for use with 192-633

142-0426

Chassis tube connector replacement kit with mounting screws

(material for 10 thermostats included)

192-525

Restrictor plate replacement kit with filters and gasket

(material for 10 thermostats included)

192-321