D4

Siemens Energy & Automation, Inc. 1000 McKee Street Batavia, Illinois 60510

SFIM-7002A-0901

Section D, September, 2001

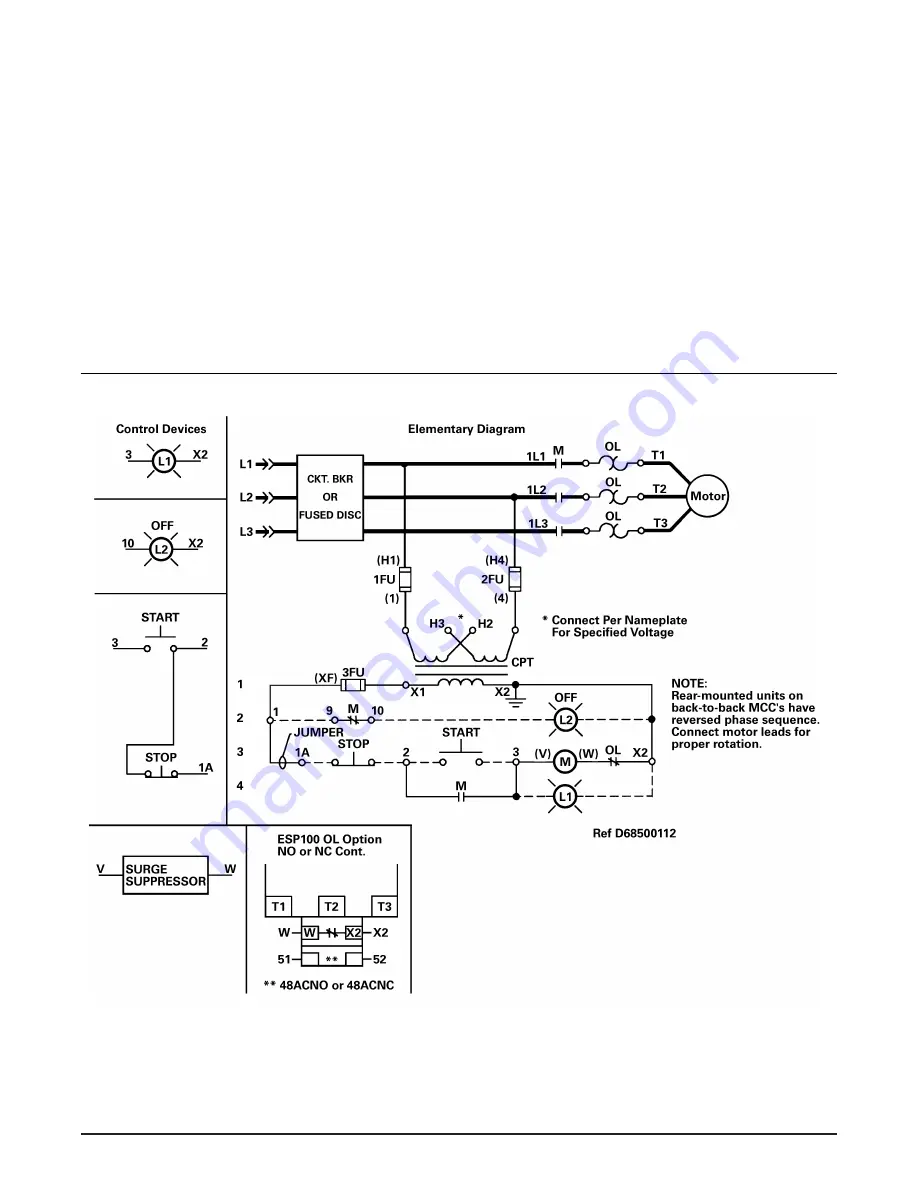

Typical Schematic

Combination Starter Ratings and

Dimensions

FVNR–High Density Full Voltage Non-Reversing

Unit With Circuit Breaker

Standard Features

• Plug-in unit, Sizes 0 - 1.

• ETI Sizes 0 - 1.

• Starters: Innova/Plus, Sizes 0 - 1, ESP100 Overload

• Electrical starter seal-in contact for 3-wire control:

Size 0 - 1, NO only.

• Control circuit terminals:

Unit stationary terminal blocks.

Summary of Contents for TIASTAR SFIM-70020

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 96: ...4 ...

Page 100: ...5 Today and tomorrow you ll know you have the very best ...

Page 115: ...13 Siemens Energy Automation Inc ...

Page 116: ...14 Siemens Energy Automation Inc ...

Page 117: ...15 Siemens Energy Automation Inc ...