Closing checklist

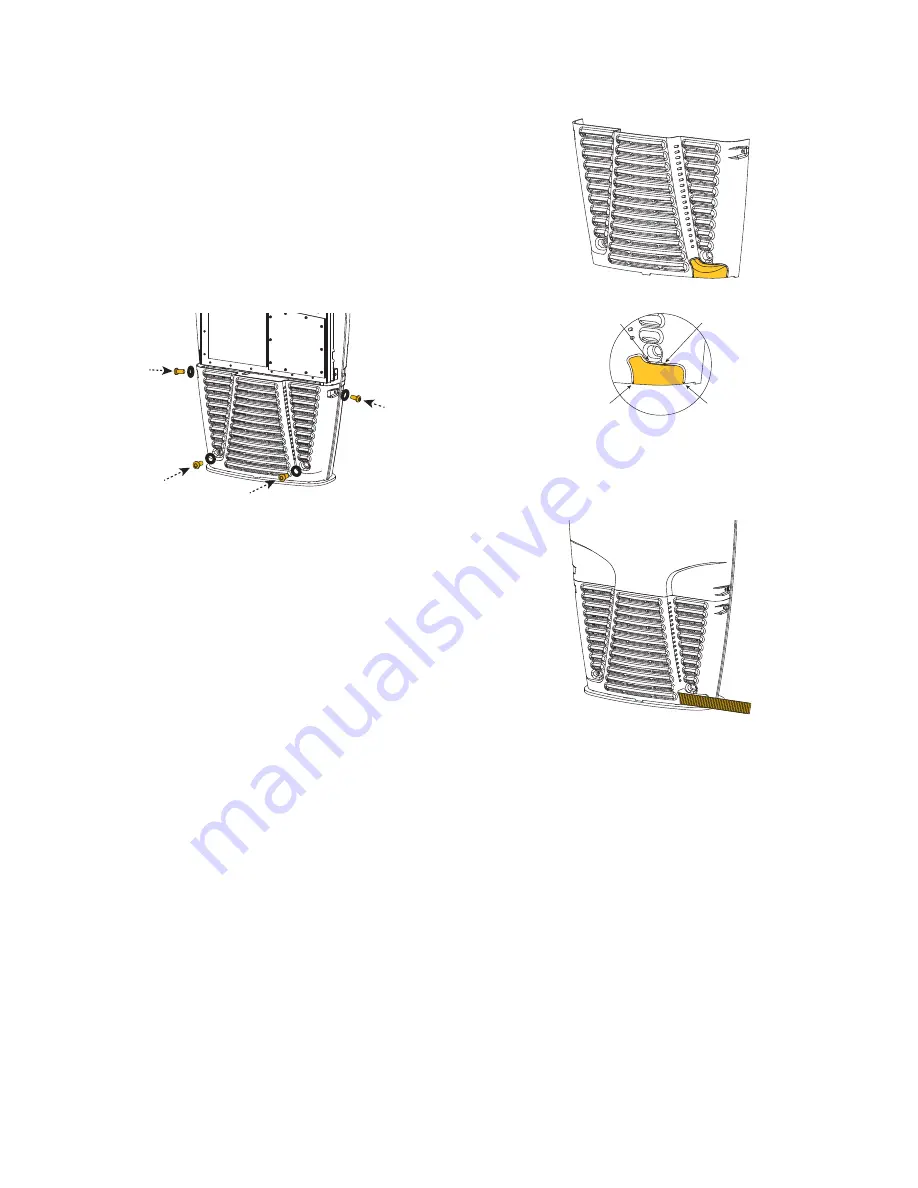

• Place the radiator onto the fixing studs.

• Fasten the radiator onto the studs with the supplied nuts

using an 8mm socket.

5. Replace cap on Ethernet port

6. Attach front/rear radiator panels

Sit the radiator panel on the base and against the metalwork,

lining up the plastic holes with the bracket nutserts. Fasten with

nylon washers and security screws using the 5mm Pin Hex tool.

Do not over tighten.

If the power is above ground, the rear radiator panel provides

the exit point for the conduit from the Ultra 50.

Cut the four tabs on the lower, right hand of the radiator

panel to remove the material to open the conduit exit point.

Replace the rear radiator panel ensuring the conduit is fitted

securely within this exit area.

If there are more than two conduit hoses (possible Ethernet

cable in conduit) place the largest at the base with the smaller

feeding above.

TAB 1

TAB 3

TAB 4

TAB 2

Installation Manual

| VersiCharge Ultra 50™

27

Summary of Contents for VersiCharge Ultra 50

Page 2: ...2 ...