Service and maintenance

8.4 Checking tightness of fastening bolts

BA 2012

40

Operating Instructions, 03/2013, 70000004024300

8.4

Checking tightness of fastening bolts

ATEX version gearboxes

Loose parts can cause sparks through impact.

Entry of foreign bodies can cause sparks.

Note

Replace damaged headless screws with new screws of the same type and strength class.

Switch off the power to the drive unit and use a torque wrench to check the seating of all

fastening bolts.

The general tolerance for the tightening torque in Nm is 10 %. The friction coefficient is

0.14 μ.

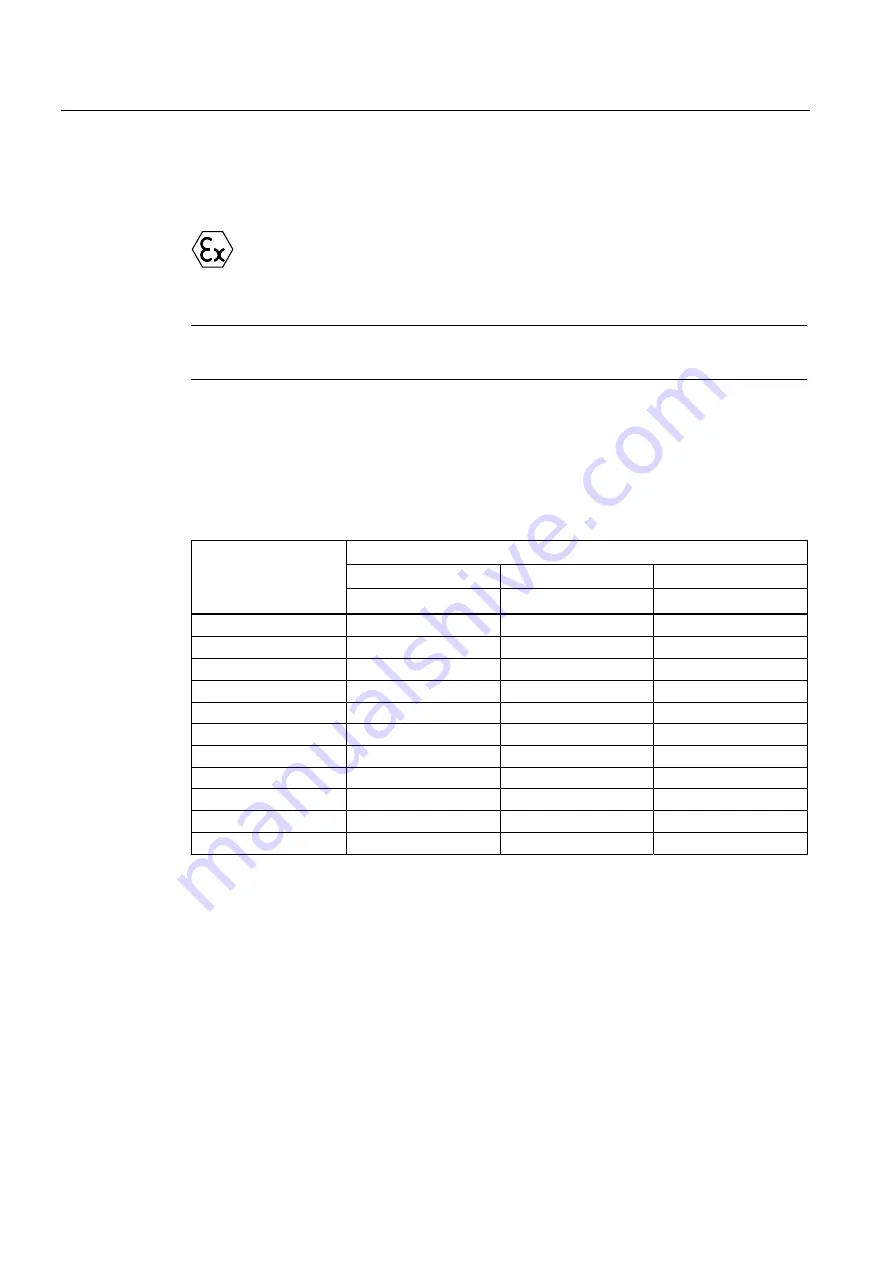

Table 8- 3

Tightening torques for fastening bolts

Tightening torque at strength class

8.8

10.9

12.9

Thread size

[Nm]

[Nm]

[Nm]

M4

3

4

5

M5

6

9

10

M6

10

15

18

M8

25

35

41

M10

50

70

85

M12

90

120

145

M16

210

295

355

M20

450

580

690

M24

750

1 000

1 200

M30

1 500

2 000

2 400

M36

2 500

3 600

4 200

Summary of Contents for Worm Gearbox S 5 BA 2012

Page 1: ...Answers for industry MOTOX MOTOX Worm Gearbox S BA 2012 Operating Instructions 03 2013 ...

Page 2: ......

Page 34: ...Commissioning BA 2012 32 Operating Instructions 03 2013 70000004024300 ...

Page 36: ...Operation BA 2012 34 Operating Instructions 03 2013 70000004024300 ...

Page 44: ...Disposal BA 2012 42 Operating Instructions 03 2013 70000004024300 ...

Page 53: ......