2

Country Club Road

P.O. Box 779

Wadesboro, NC 28170 USA

TEL: (800) 477-5003

FAX: (800) 374-6853

HOIST SPECIFICATIONS

All cable hoist models are designed for lifting and pulling loads

up to rated capacities listed on the hoist nameplate. Features

include a winding wheel for taking up slack or free stripping of

the cable and a handle designed to bend before any

mechanical part of the hoist is subjected to damaging

overload. The handle may be inserted into the U-Frame socket

from either direction to facilitate use in confined areas or to

allow the operator to pull against the load under unusual

conditions. A double, interlocking pawl system provides

positive load control at all times. Refer to Table 1 for model

specifications.

OPERATION

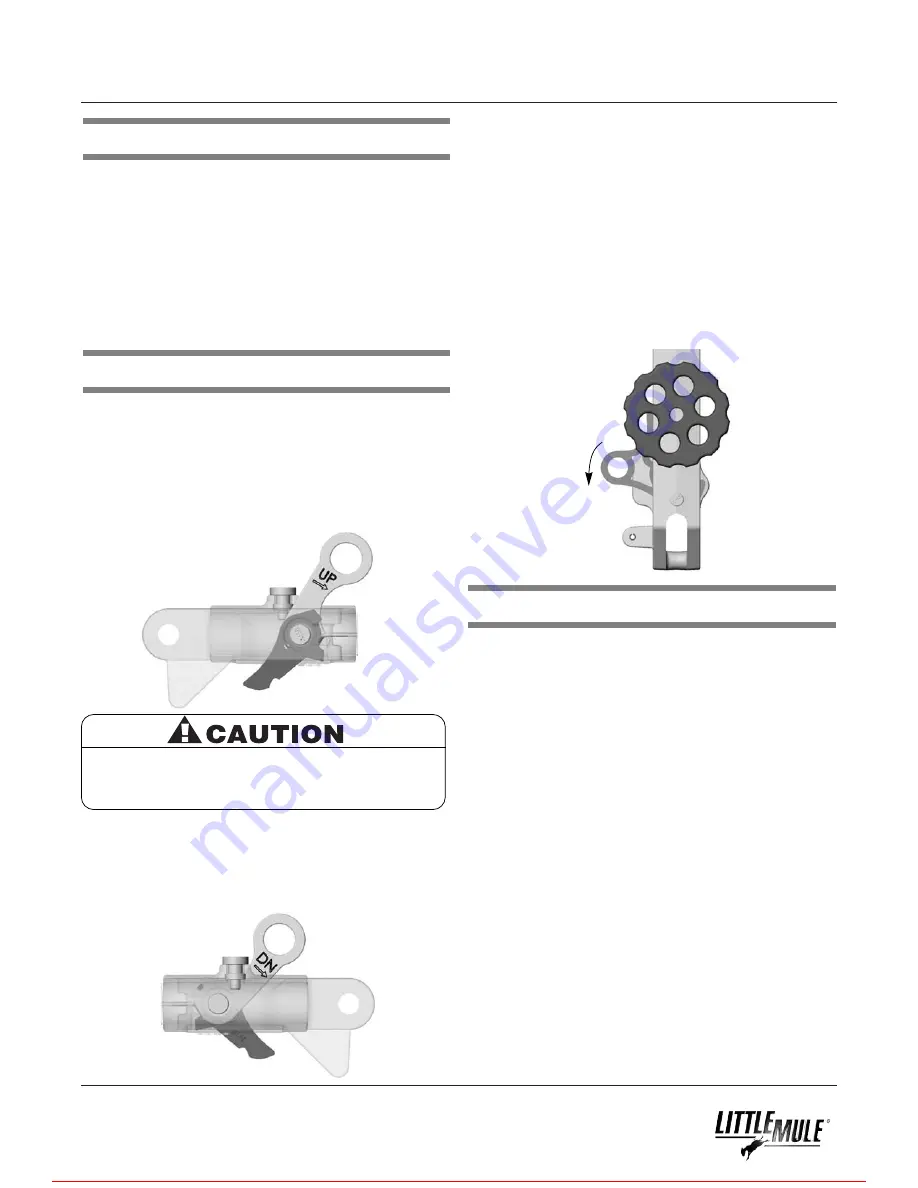

LIFTING OR PULLING

Place the reversing lever in the up position, engaging the

loading pawl against the ratchet teeth. Work the handle as

required to achieve desired lift or tension. The handle may be

inserted into either end of the U-frame socket enabling user to

work in restricted areas. Never use a “cheater” bar or handle

other than those approved by the manufacturer.

LOWERING

Place the reversing lever in the down position and operate the

handle to its extreme down position until the load is removed

from the holding pawl. As the handle is slowly released, the

load will be lowered by one notch. To continue lowering repeat

this operation. The lowering of heavy loads is easier if quick

(sharp) downward handle motion is used.

FREE-WHEELING

Before attempting to free-wheel make certain the hoist is not

loaded. To release the cable for free-wheeling, the reversing

lever must first be in the down position. Press the free-wheel

lever. The cable may now be stripped from the drum to facilitate

more rapid positioning while attaching to the object to be pulled

or lifted. The hoist will not free-wheel if it has a minimum of 40

pounds of load/tension. Similarly, excess slack may be quickly

and easily rewound on the drum using the winding wheel.

MAINTENANCE

Maintenance of the hoist is normally limited to cleaning and

lubrication. The hoist should always be lubricated following

each cleaning operation to replace any lubricants that were

washed away.

CLEANING

Occasional cleaning of the cable hoist will increase operating

efficiency and decrease wear on friction parts. Clean with an

approved solvent or kerosene, applying liberally with a brush or

cloth. Lubricate the cable hoist after cleaning.

LUBRICATION

Lubricate the following areas weekly with a light grease:

a. ratchet teeth of drum.

b. contact points between U-frame and free-wheel lever.

c. contact points between pawl and pin (H5230-31).

Lubricate the following areas weekly with SAE 20-30 gear oil:

a. rotating points of shafts, with the exception of the drum

shaft.

b. hook shanks

Only small amounts of lubricants need to be applied.

DO NOT saturate areas with grease/oil.

DO NOT allow lubricants to contact cable.

FREQUENT INSPECTIONS

Figure 1

Figure 2

Figure 3

Free-

Wheel

Rig hoist properly so that the hoist is free to align

with the direction of pull. Avoid side loading. Hoist

frame should not bear against anything and should

be free to align with hooks.

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com