4

Country Club Road

P.O. Box 779

Wadesboro, NC 28170 USA

TEL: (800) 477-5003

FAX: (800) 374-6853

IIN

NS

SP

PE

EC

CT

TIIO

ON

N A

AN

ND

D M

MA

AIIN

NT

TE

EN

NA

AN

NC

CE

E C

CH

HE

EC

CK

K L

LIIS

ST

T

L

LE

EV

VE

ER

R O

OP

PE

ER

RA

AT

TE

ED

D C

CA

AB

BL

LE

E H

HO

OIIS

ST

T

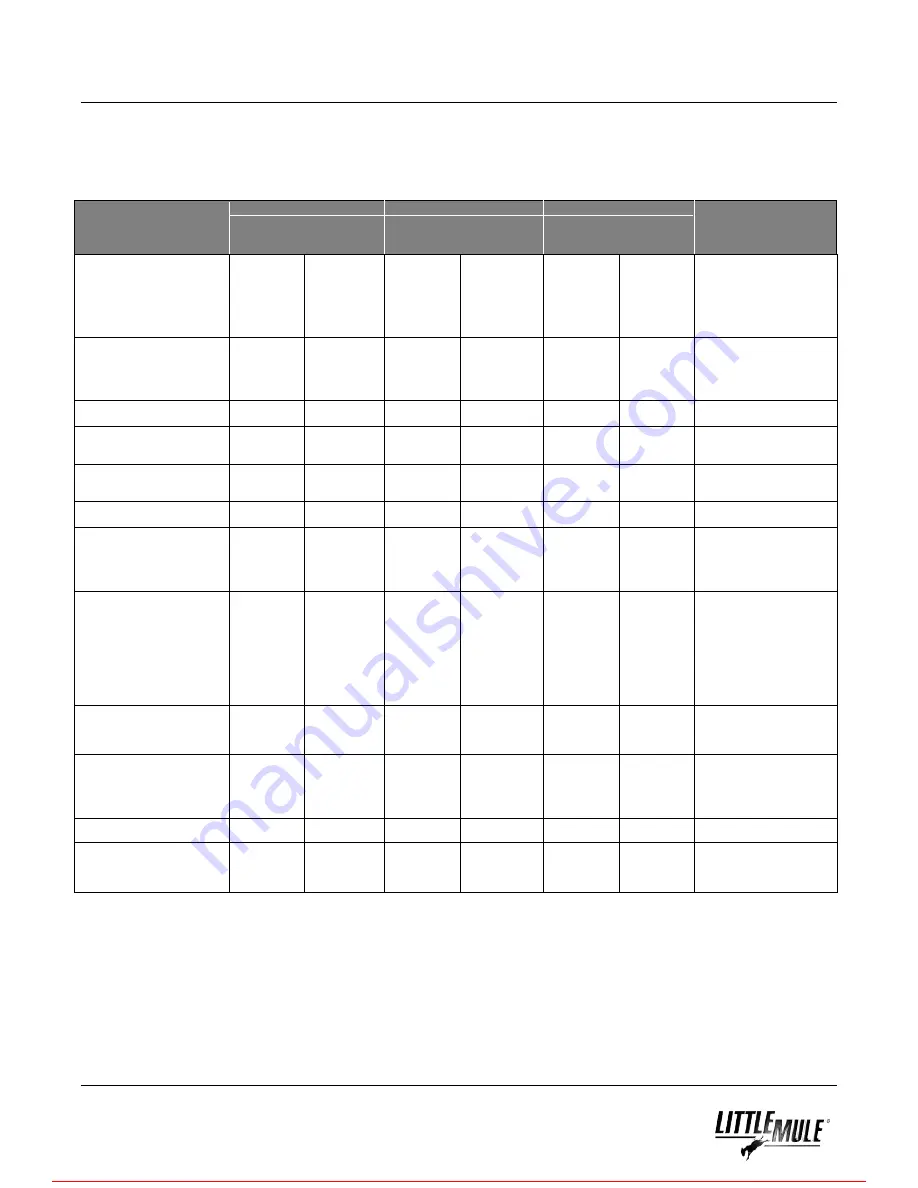

Type of Hoist ______________________________________________________

Capacity (Tons) ____________________________________________

Location _________________________________________________________

Date Placed in Service ______________________________________

Manufacturer______________________________________________________

Manufacturer’s Serial No._____________________________________

Normal Service

Heavy Service

Severe Service

Item

Visual

Record

Visual

Record

Visual

Record

Monthly

Yearly

Weekly

6 Months

Daily

Monthly

Remarks

FREQUENT INSPECTION

All functional

*

*

*

mechanisms for

proper operation

Hooks and latches for

*

*

*

deformation, chemical

damage, cracks & wear

(See ASME B30.10)

Hook latch operation

*

*

*

Cable/Wire Rope (See

*

*

*

Wire Rope Inspection)

Levers for bends,

*

*

*

cracks, etc.

Hoist support for damage

*

*

*

PERIODIC INSPECTION

Evidence of loose pins,

**

***

***

bolts, nuts or rivets

Evidence of worn,

**

***

***

corroded, cracked or

distorted parts such

as suspension frame,

levers, cable

attachments, yokes,

shafts, pins and

rollers

Evidence of damage to

**

***

***

hook retaining nuts

and pins

Evidence of worn pawls,

**

***

***

cams or ratchet;

corroded, stretched or

broken springs

Warning label

**

***

***

End connections of

**

***

***

wire rope

NORMAL SERVICE - Weekly usage

HEAVY SERVICE - Daily usage

SEVERE SERVICE - Daily usage and/or in severe weather conditions (rain, snow, ice, etc.)

NOTE:

All hoists are load tested at 125% of the rated capacity at the manufacturer. If load sustaining parts are altered, replaced

or repaired, the hoist must be load tested at rated capacity. This inspection and maintenance check list is in accordance with

our interpretation of the requirements of the Safety Standard for Manually Lever Operated Hoists ASME B30.21. It is, however,

the ultimate responsibility of the employer/user to interpret and adhere to the applicable requirements of this safety standard.

Figure 4 — Recommended Inspection and Maintenance Check List

*

Visual inspection by operator or other designated personnel.

**

Visual inspection by designated person of conditions.

***

Visual inspection by designated person of conditions unless conditions indicate that disassembly should be done to permit detailed inspection.

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com