9

The SifWeld Cut100 is a professional 100Amp 3ph plasma cutting system designed for hand-held efficient

cutting in the heavy fabrication, manufacturing, demolition and general maintenance industries.

Featuring IGBT inverter technology, the SifWeld Cut100 plasma cutter is engineered to consistently deliver

heavy-duty cutting performance. This is ideal to cut up to 30mm thick steel. The 6m high-frequency

cutting torch ensures exceptionally smooth, clean cuts, and comes with a quick-connect central adapter

to ensure effortless connection and cost effective replacement of the torch.

The SifWeld Cut100 can be used to efficiently cut mild and low-alloy steels, stainless, aluminium, copper,

titanium and nickel alloys.

Features

• 100amp cutting power

• High 60% Duty cycle

• 30mm clean cut on steel

• 35mm severance cut on steel

• Industrial quality metal chassis

• High power efficiency

• Low energy consumption

• Clear, vibrant LED display

• High portability

• Optional Trolley

1.2 Introduction

8

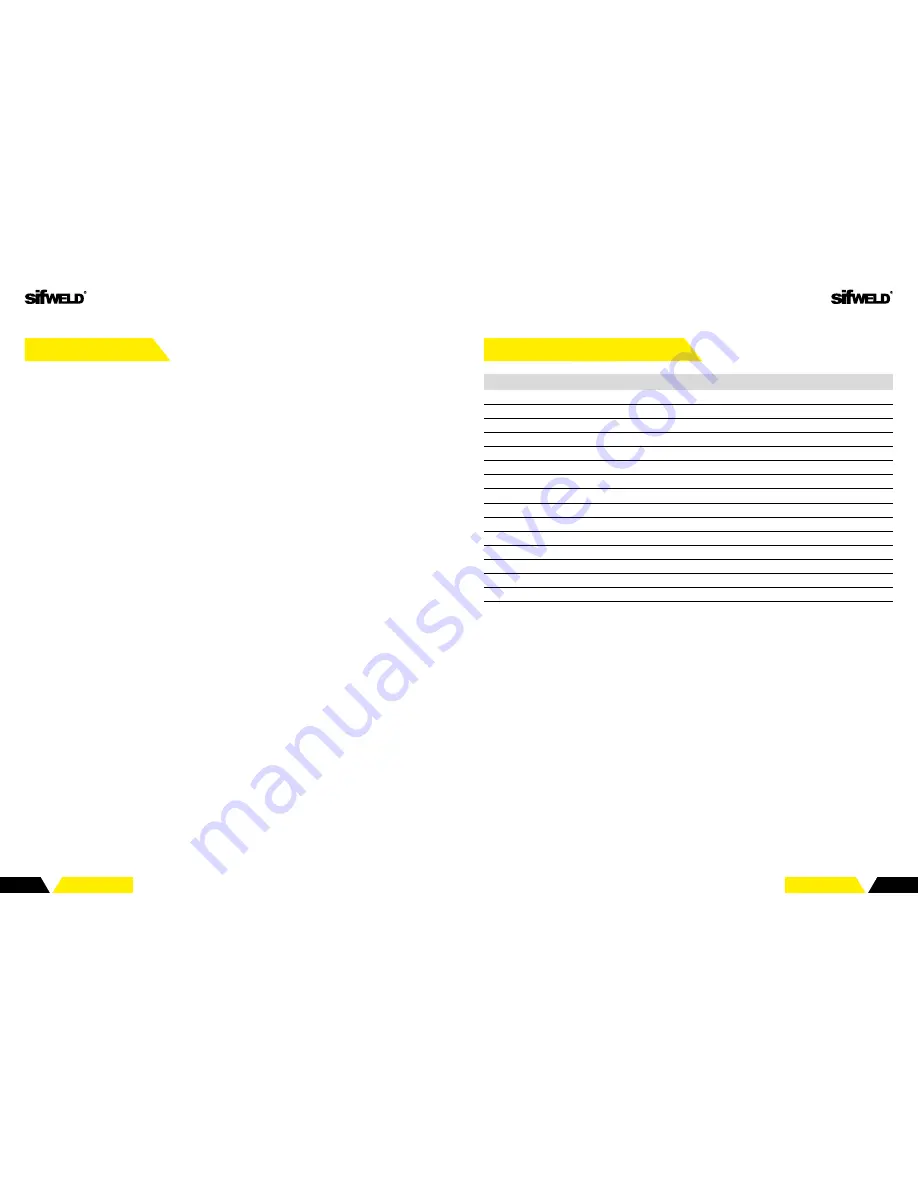

1.3 Technical Specifications

SifWeld CUT 100

Power supply (V)

400V 15%

Frequency (Hz)

50/60

Rated input (KVA)

14.1

Open circuit voltage

280

Amperage range (A)

30-100

Rated Duty cycle (%)

60

Rated working voltage (V)

92-120

Efficiency

0.85

Power factor

0.93

Max cutting thickness (mm)

35

Compressed air pressure required

5.0 bar (72 PSI)

Dimensions (LxWxH)(mm)

685 x 295 x 560

Post flow time(S)

4

_+

Input power supply

3ph

Compressed air flow required

140 - 170 lpm (5 - 6 CFH)

Summary of Contents for CUT 100

Page 10: ...18 19 Notes ...