34

INSTALLATION & OPERATION

3

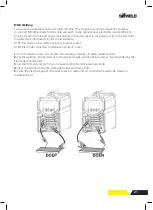

(7) Connect the gas line to gas connector on the rear panel.

(8) Connect the power cord of welding machine with the outlet on electrical box.

(13) Carefully open the gas cylinder valve and set the required gas flow rate.

(14) Set welding parameters using the knobs as shown on digital displays.

(11) Feed the wire through the drive

rolls and into the inlet guide tube.

Tighten the wire tension swing arm.

(12) Pull the trigger to drive the wire down

the neck until it exits the contact tip.

(9) Remove the spool cover by pressing

button and lifting off the cover.

(10) Place a spool of wire inside the

spool holder on post.

INSTALLATION & OPERATION

3

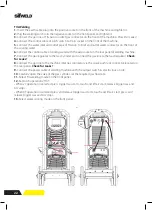

(7) Connect the gas line to gas connector on the rear panel.

(8) Connect the power cord of welding machine with the outlet on electrical box.

(13) Carefully open the gas cylinder valve and set the required gas flow rate.

(14) Set welding parameters using the knobs as shown on digital displays.

(11) Feed the wire through the drive

rolls and into the inlet guide tube.

Tighten the wire tension swing arm.

(12) Pull the trigger to drive the wire down

the neck until it exits the contact tip.

(9) Remove the spool cover by pressing

button and lifting off the cover.

(10) Place a spool of wire inside the

spool holder on post.

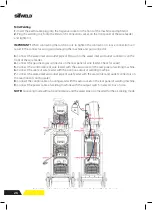

9.

Remove the spool cover by pressing

button and lifting off the cover.

10.

Place a spool of wire inside the

spool holder.

11.

Feed the wire through the drive rolls and

into the inlet guide tube. Swing back and clip down

the wire tension swing arm.

12.

Pull the trigger to drive the wire through the

neck until it exits the contact tip holder.

13.

Carefully open the gas cylinder valve and set the required gas flow rate.

14.

Select spool gun mode using the knob. Set welding parameters using the knobs.

Summary of Contents for Evolution MTS400 SYN

Page 39: ...39 Notes ...