TSX1D200MTS V1 FEB13

- 24 -

7

Daily Checklist and Routine Maintenance

Daily Checklist

These checks should be performed each time prior to using the SifWeld MTS200 unit, to ensure the unit is it

perfect condition to avoid any issues

Power Source

Section

To Check

Note

1. Switch operation, all connections and

general machine are in good condition

Operation Control Panel

2. Check power light turns on and off

Cooling Fan

1. Check air flow and sound of fan are normal

If the fan does not work, and no

sound can be heard the fan

needs repair.

1. When power is on, check for shaking or

buzzing sound

2. When power is on, check for peculiar smell

Power Section

3. Check for overheating by any colour

change on the unit

1. Check whether the gas pipeline is

damaged or the connection is loose

Periphery

1. Check the outer shell and other parts are

not loose

Welding Gun

Section

To Check

Note

1. Whether this is securely fitted

Nozzle

2. Clear of spatter

1. Whether this is securely fitted

Contact Nozzle

2. Damage to the tip or if blocked

1. Ensure the correct liner size is chosen for

the wire diameter being used

2. Check for kinks in the liner

3. Check for dirt and blockages in the liner

4. Check for kinks in the wire

This can cause extra erosion to

the liner

Wire Hose

5. Check for damage to the O-Ring

This can cause leaking gas and

effects the weld

Summary of Contents for MTS 200

Page 1: ...MTS 200 User Manual SWMTS001 TSX1D200MTS ...

Page 9: ...TSX1D200MTS V1 FEB13 9 Diagram for Installation for MIG Applications ...

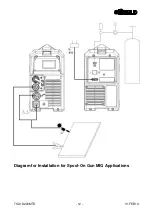

Page 12: ...TSX1D200MTS V1 FEB13 12 Diagram for Installation for Spool On Gun MIG Applications ...

Page 14: ...TSX1D200MTS V1 FEB13 14 Diagram for Installation for TIG Applications ...

Page 16: ...TSX1D200MTS V1 FEB13 16 Diagram for Installation for MMA Applications ...

Page 22: ...TSX1D200MTS V1 FEB13 22 4 Hot Start ...

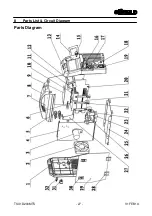

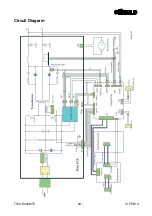

Page 27: ...TSX1D200MTS V1 FEB13 27 8 Parts List Circuit Diagram Parts Diagram ...