NOTE: Engines in the .40 to .46 size range are right at the break

point between using 4-40 size or 6-32 size mounting bolts. Some

.40-.46 engines have small holes in their case for 4-40 bolts, while

other .40-.46 engines have holes large enough to accommodate

6-32 bolts. Be sure to buy the size appropriate for your engine.

❑

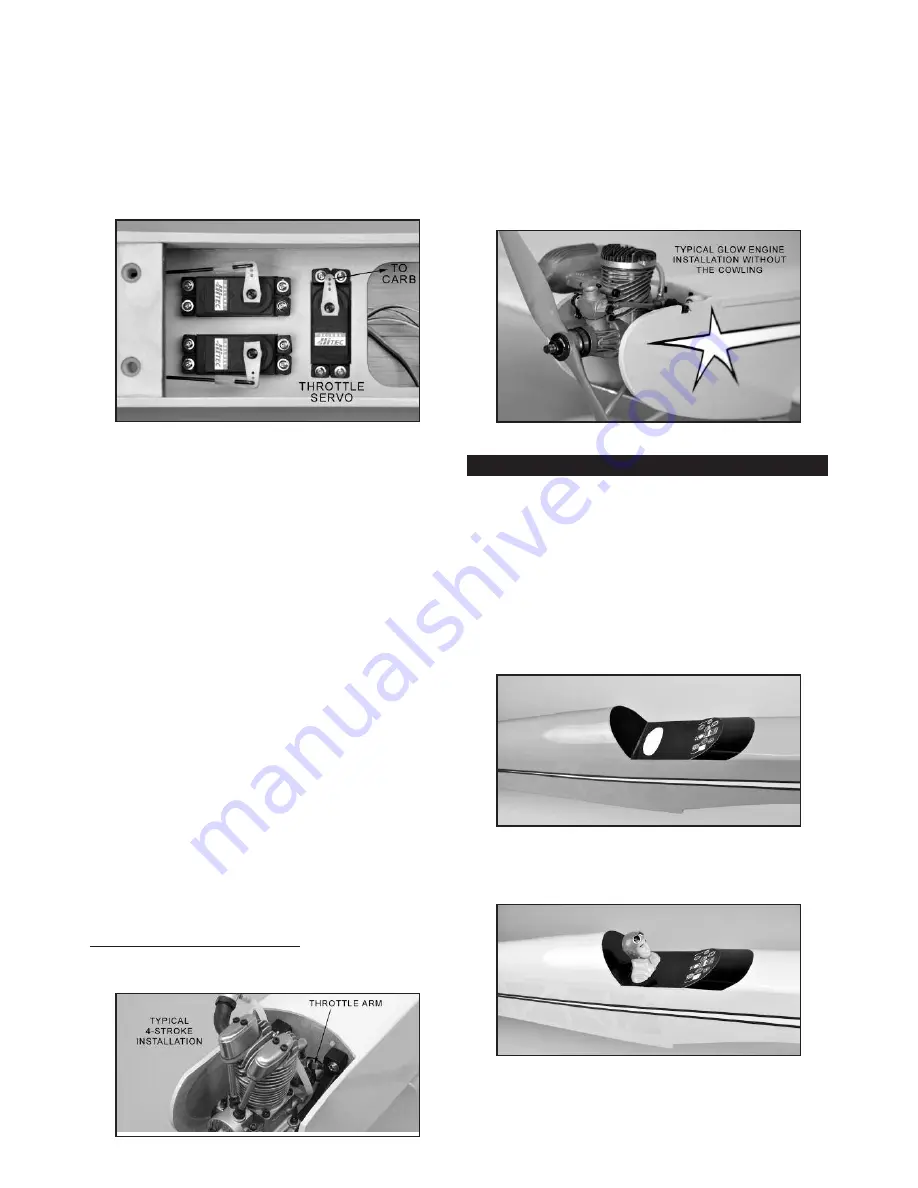

44) 2-STROKE THROTTLE PUSHROD

a) Mount your throttle servo in the middle opening of the servo

tray in the fuselage. Put the control arm end of the servo on the

same side of the fuselage as you engine’s carburator control arm.

b) The supplied throttle pushrod assembly consists of a wire

pushrod running inside a nylon pushrod tube. Install the Z-bend

end of the pushrod in the throttle servo arm. The plain end of the

pushrod wire will connect to the carburetor control arm with a

metal pushrod keeper, which allows you to easily adjust the overall

length of the pushrod.

c) Determine which side of the airplane your throttle pushrod

will be on. Typically for 2-stroke engines it will be on the right side

of the fuselage. For 4-stroke engines it is often on the left side.

Then determine the exact route your pushrod will take to connect

to the throttle servo and the engine’s throttle arm. In most cases

you will want the pushrod to run right alongside the engine mount

and fuel tank, and then angle over to the throttle servo arm.

d) Drill a hole through the firewall for the nylon pushrod tube

to pass through. Be careful not to drill a hole in your fuel tank!

e) The nylon pushrod tube is provided extra long so it can be

adapted to many variations in equipment. Determine how long it

should be for your installation. For a typical 2-stroke setup you

will want about 1” of tube sticking out in front of the firewall, and

the other end of the tube to stop about 1” away from the throttle

servo. Mark and cutoff the tube to the appropriate length, and

then install it in the airplane, gluing it securely to the firewall.

f) Install the metal pushrod keeper in the carburetor control

arm, with one hex nut on each side of the arm.

f) Slide the wire pushrod into the airplane from the back until

you can install the Z-bend in the throttle servo arm.

g) Turn on your radio and adjust the length and travel of the

throttle pushrod using the pushrod connector at the carburetor.

Note: You may find it necessary to support the servo end of the

outer nylon pushrod tube with a scrap of balsa, plywood, or foam,

to keep the pushrod from flexing.

Note about 4-Stroke Throttle Pushrod

4-Stroke glow engines typically have their carburetor on the back

of the engine, which puts the throttle arm very close to the firewall

14

of the airplane. Using the pushrod connector on the carburetor

end of the pushrod, and the Z-bend at the servo end, should work

in most cases.

❑

45) COWLING

Some glow engine fliers do not use the supplied Fiberglass Cowl-

ing, preferring to keep the front of the airplane open for easy ac-

cess to the engine for fueling and service. If you do want to use

the cowling you will need to cut a large opening in the top of the

cowling for the engine head to stick out. Step 35) on page 12 of

this manual describes mounting the cowling.

For this section you will need the Fuselage and:

(1) Painted Pilot Figure

(1) Clear Plastic Canopy

❑

46) Test fit the pilot figure in the cockpit area. Check to make

sure that the canopy will fit over the pilot and reposition if needed.

Once you have the pilot in a good position trace around the base

of the pilot with a felt pen. Using a razor blade, cut through the

covering just inside your markings so you can expose the bare

wood. Exposing the balsa will provide a stronger bond, insuring

that the pilot will not “bail out” during aerobatics.

❑

47) Using epoxy or a silicone based adhesive, glue the pilot to

the cockpit base and let it dry. It is not recommended to use CA

glue as it may break loose over time.

❑

48) Double check the fit of the canopy to make sure it is ready

to install. Make any final changes to the cockpit area at this time.

Make sure the canopy is clean inside. Once it’s glued down it will

be impossible to clean later.

PILOT & CANOPY