.

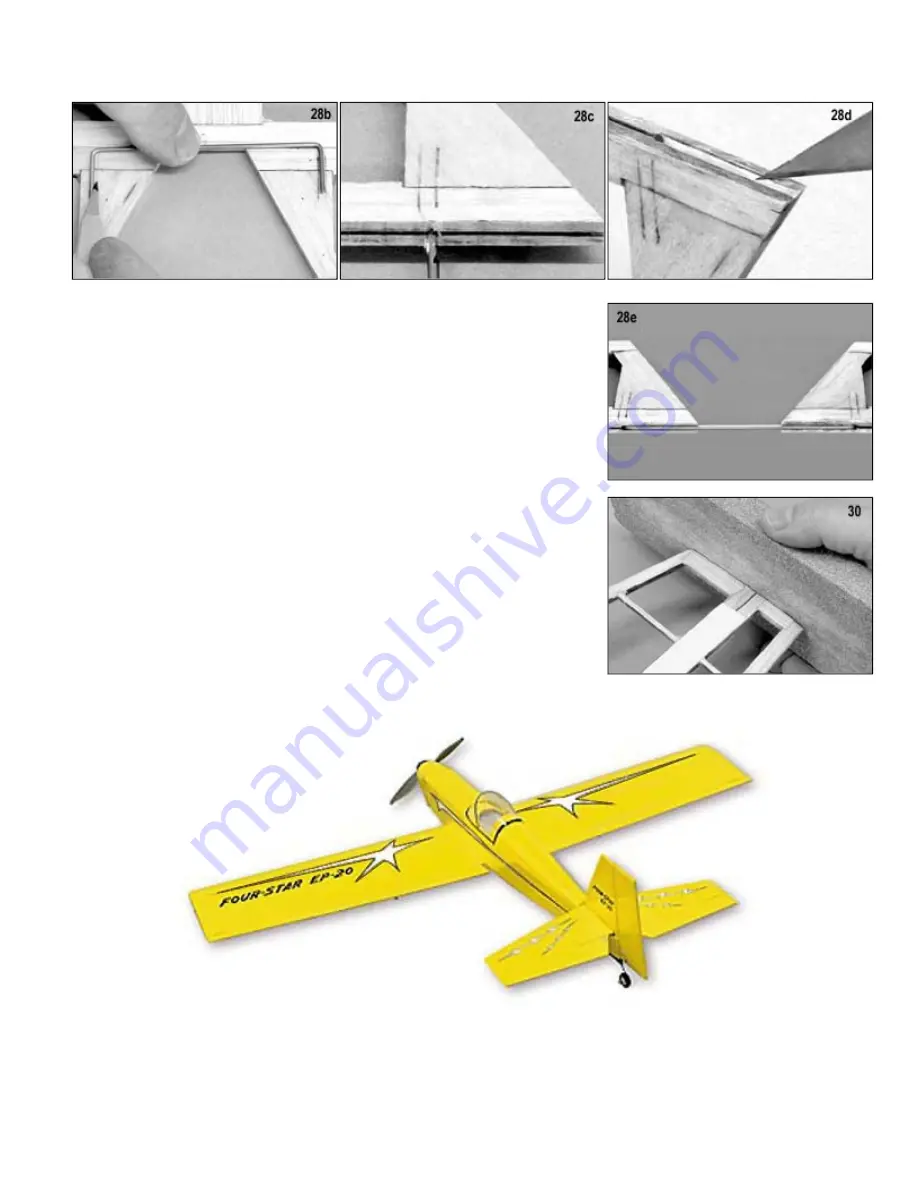

d. Use a sharp #11 hobby knife to cut a groove in the leading edge to accept the Wire Joiner.

e.

Wipe the Wire Joiner clean with some type of solvent (paint thinner, mineral

spirits, rubbing alcohol, etc.), and then glue it into the elevators with epoxy. Be

sure to keep the leading edges of the two elevators aligned straight while the glue

dries.

f.

Use a sanding block to bevel the leading edge of the elevators to a "v" shape,

using the hinge line as a guide. Refer to the cross-section drawing of the elevator

on the plan.

29.

Assemble all the fin and rudder parts over the plan. When dry, remove them from

the plan and sand them to final shape. Fin - round the leading edge, leave the

trailing edge square. Rudder - round the trailing edge, "v" shape the leading edge.

30.

Temporarily tape the elevators to the back of the stabilizer. Then use a sanding

block to sand the ends of both pieces together until they match perfectly. The tips

can be left square or sanded round if you prefer.

The tail surfaces are now complete and can be set aside until covering. They will

be hinged after covering is done.

Summary of Contents for Four-Star 20EP

Page 5: ... ...