.

65. Be sure and epoxy the blind nuts to the back of the firewall so they will not come out later when it may be necessary to take

off the mounts. Work some under the nuts but don't get epoxy into the threads of the bolts. Pull the blind nut points tight into

the wood with the bolts before the glue sets up. With the mounts and nose gear bracket in place, cut off the mounting bolts

for both flush with the face of the blind nuts on the back of the firewall. This is to prevent any chance of the bolt ends

puncturing the tank.

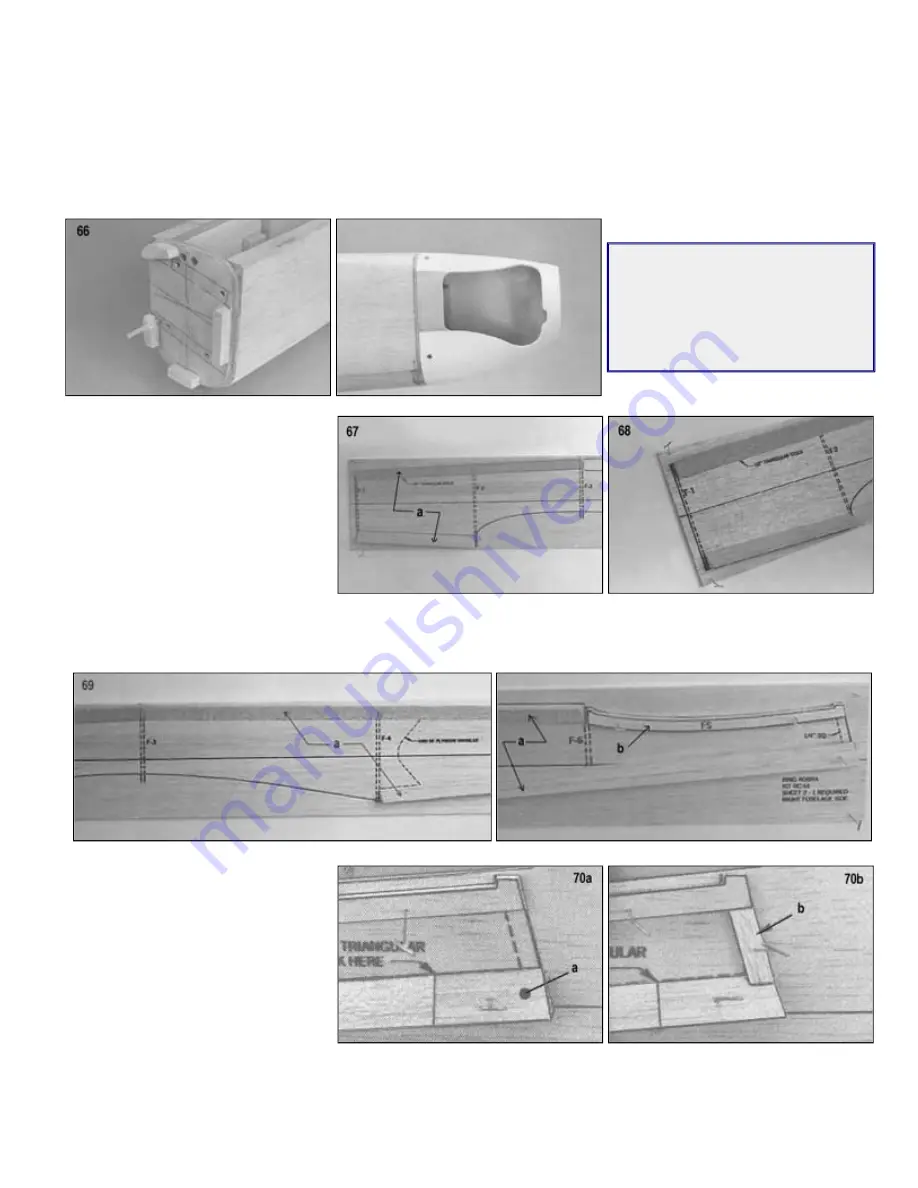

66.

Since the cowl is now finally placed, you can add the 3/8" sq. hardwood mounting blocks to the firewall whenever it is

convenient. Shape the blocks to fit snugly against the cowl.

For a neater opening on the prototype,

we saved the sawn out portion of the

back of the cowl and glued a piece of it

permanently onto the fuselage. This

filled in the opening behind the engine

and gave a more finished look to the

installation.

67.

a. Cut the front pieces of 1/2"

triangular stock to size and glue

on the fuselage sides

68.

Note the placement of the triangular

stock at the front. The bottom stock is

placed flush with the dotted line to allow

space for the firewall.

69.

a. Glue on pieces of 1/2" triangular stock on the back of the fuselage sides.

b. Glue the stabilizer saddle FS in place.

70.

a. Complete the bottom 1/2"

triangular piece.

b. Glue a piece of 1/8"x1/4" scrap at

the back of the sides.

71. Mark the locations of the F-2 and F-3

formers on the 1/2" triangular stock.

72.

Fit the 1/16" plywood die cut doublers FD

to the sides.

73.

a. Glue FD in place.

b. Mark the location of the bottom of F-3 on the doubler.

c. Draw the datum line on the doubler.