.

24. Position the landing gear and drill a 5/32" diameter hole

into the gear block and anchor block.

CAREFUL!

It is easy to slip and go clear through the wing.

Trim the edge of the hole so that the radius of the wire at the bend will fit down into it. The gear should fit into the block snugly, but not so

tightly that it will jam in the block. You may want to remove it later for straightening after a hard landing. Place a nylon landing gear strap

held on by No. 2 screws across the gear at each end to retain the gear in the groove.

25.

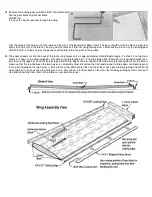

The angle already cut into the ends of the foam wing halves sets an approximately correct dihedral angle. To check it, set up the wing

halves as shown in the drawing below, with each wing tip blocked up 1". Sand the wing ends (Photo 25) as required to make the center

joint fit correctly together. Glue the halves together with Sig Epoxy Glue or Sig Kwik-Set Glue. Use plenty of glue where the balsa sheeting

meets so that the joint between the two halves is completely filled. Be certain that the leading and trailing edges are lined up exactly so

that no twist between the two halves is built into the wing. Mark center lines on the ends of each panel before joining and match the lines

when joining. If you have the wing sitting on a true, flat surface, a further check on twist can be made by putting center marks on the tips

also and measuring from them to the table as a second reference.