Typically a modern .25 size engine, (like the Norvel .25), will fly with

a 9 x 4, 9.5 x 4.5, or 10 x 4 propeller. A .35 or .40 size engine will

fly with a 10 x 5 or 10 x 6 prop. Ultimately, final propeller selection

is a matter of testing in flight. Refer to your engine manufacturer’s

instructions for more guidance in selecting a suitable propeller.

CONTROL LINES (not supplied)

The Primary Force should be flown on .015” dia. x 60 - 63 ft. long

braided steel cable control lines.

NOTE ON “LAP TIMES”

Most serious C/L stunt fliers tailor their line length, prop selection,

and engine run to give them a certain airspeed. They check their

airspeed by using a stop watch to find out how long it takes the

airplane to fly one lap of normal level flight. Our flight tests indicate

that the Primary Force flies best at lap times of 5.0 - 5.3 seconds.

COVERING MATERIAL

Your Primary Force has been professionally covered with SIG

AEROKOTE

®

iron-on plastic covering material.

The colors used on the Primary Force are AEROKOTE

®

#SIGSTL321 Bright Orange, and

#SIGSTL100 Brilliant White

Wrinkles In The Covering! After you remove the covered model

parts from their plastic bags, you may notice within the first couple

days that some of the covering material may become slack or

wrinkled. If that's the case, there is no need to be alarmed. The

covering is not defective! Your Primary Force was covered in a

part of the world which has consistantly high humidity and some

of that moisture is retained in the balsa wood when the parts were

put in the bags. When exposed to drier air, the wood loses the

excess moisture, dimensionally shrinking slightly in the process.

In turn, this shrinkage may cause some slight relaxing of the

covering, causing wrinkles to appear.

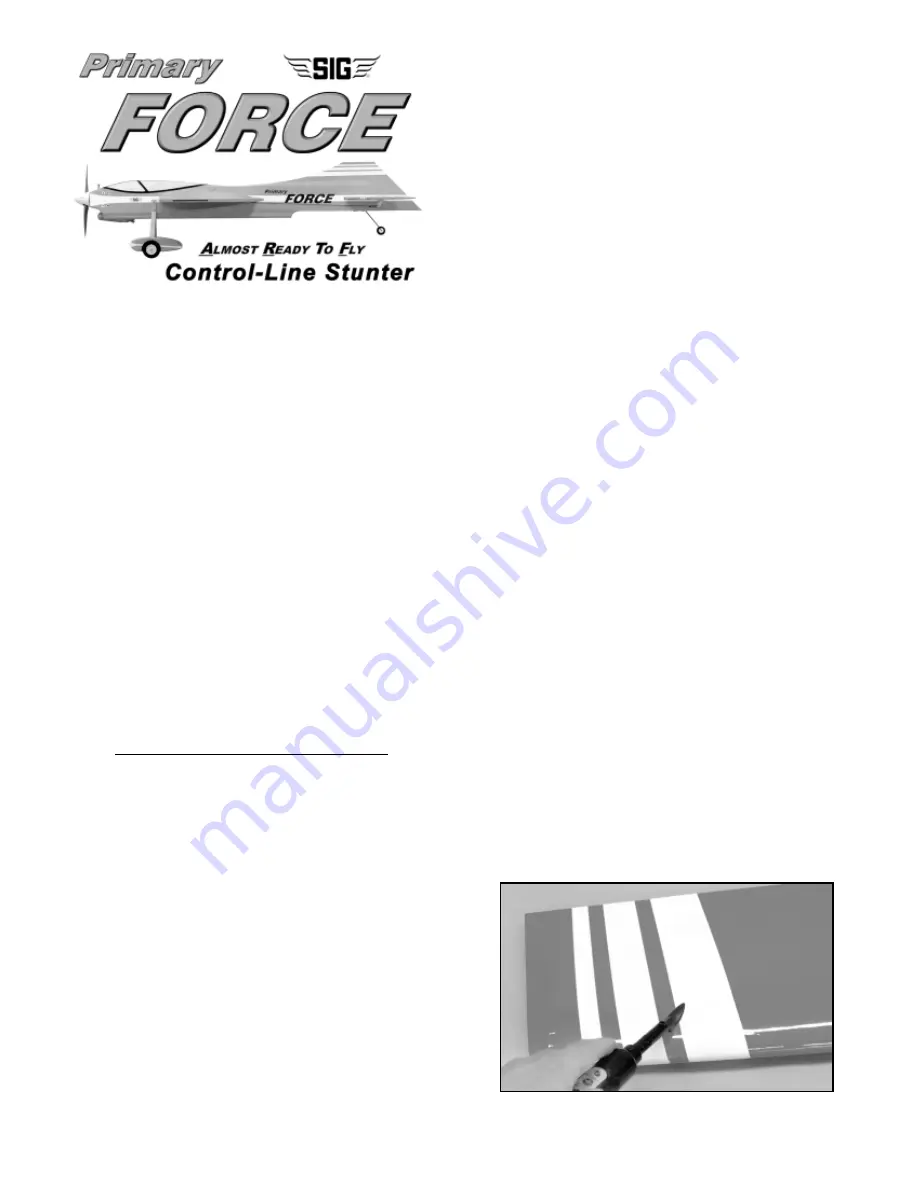

Any wrinkles that appear in the covering are easy to remove by

applying a little heat from a modeler's “covering iron” or small “trim

seal” iron. Be very careful if you are using a “heat gun” to tighten

up loose covering. A heat gun spreads the heat over a very large

area and can cause seams to “crawl” if you are not careful.

The best procedure is to first use a small trim seal iron to go over

all the seams and color joints in the covering, making sure they

are all sealed down and well adhered. Then, hold the hot iron over

the wrinkle to lightly shrink the material - do not press on it. Once

the covering is tight, lightly iron it back down to the wood. Use

caution whenever the hot iron gets close to a seam in the

covering. Over-heating a seam can cause the covering to creep,

exposing the wood underneath.

For reshrinking AEROKOTE

®

set your iron temperature to

approximately 220

O

- 250

O

F (104

O

- 121

O

C).

1

INTRODUCTION

Congratulations on your purchase of the SIG Primary Force ARF.

The reason for the name "Primary" is that this contest winning

stunt ship is really easy to build, trim, and fly.

It makes an

excellent model for the beginning stunt flyer and expert alike. It will

teach you the basic trimming skills needed to be a competitive

stunt flyer without the complexity of a flapped model. Most experts

that have flown the Primary Force like it for its simplicity and praise

it for its honest and superb flying characteristics. The Primary

Force can fly the entire AMA stunt pattern with a level of

smoothness and "flow" that has up to now only been associated

with flap-equipped stunt ships. The Primary Force is equipped

with all the modern day trimming devices and can be flown with

many of the existing .25 to .40 stunt engines.

EASY TO ASSEMBLE

Assembly of your Primary Force ARF is fast and simple when

following the detailed instructions in this manual.

A low parts

count and professional engineering ensure quick and easy

assembly. All parts are CAD-drawn and laser-cut, which means

that everything fits the way it should. The airplane has been

carefully jig built, yielding a straight and true airframe. The light

weight structure is covered and finished in SIG AeroKote

®

polyester film.

We urge you to read through this instruction

manual first, before starting assembly, to familiarize yourself with

the various aircraft parts and assembly sequences.

Technical Specifications PRIMARY FORCE

Wing Span:

50.8 in.

1290 mm

Wing Area:

500 in.

2

32.3 dm

2

Length:

39.5 in.

1003 mm

Flying Weight:

36 - 40 oz.

1020 - 1134 g

Wing Loading:

10.4 - 11.5 oz./ft.

2

31.6 - 35.1 g/dm

2

ENGINE (not supplied)

The Primary Force ARF was designed for light weight 2-stroke

glow engines in the venerable "Fox .35 Stunt" power range. In this

modern era that can include many fine engines from .25 cu. in. up

to .40 cu. in. (4.1 - 6.5 cm

3

). The choice is yours, based on your

personal preference and availability.

For the record, we’ve seen the Primary Force design powered by

the following engines (old and new), all with excellent results: Fox

35 Stunt, OS Max 35S, McCoy 35/40 Redhead, OS 25FP, OS

25LA, OS 40FP, OS 40LA, Brodak 40. Here at the SIG factory, we

have also been using the Norvel .25 BIG MIG and the Norvel .25

BB AME engines with good results.

PROPELLER (not supplied)

Due to the wide range of suitable engines for the Primary Force, it

is impossible to recommend one “best” propeller for all situations.