The wings are designed as a 2-piece system, with separate right

and left wing panels joined by an aluminum tube Wing Joiner and

a hardwood locating Pin at the rear. Due to the high strength of

the wing joiner tube, the wing panels do not need to be perma-

nently glued together. Gluing them permanently together is op-

tional - your call. The obvious benefit to leaving the wing panels

separate is the fact that they can be easily transported or stored,

requiring a minimum of space.

To help protect your wings during the following steps we recom-

mend that you cover your work surface with a soft cloth or piece

of foam.

INSTALLING THE AILERON SERVOS

For the following steps you will need:

(1) Right Wing Panel

(1) Left Wing Panel

(1) Aluminum Tube Wing Joiner

(2) Servos with Mounting Screws (not furnished)

(2) 6” Servo Extension Cords (not furnished)

(1) Servo Y- Harness (not furnished)

❑

1) Mount the aileron servos in the bottom of each wing panel.

a) The servo bays are precut for you but you’ll want to double

check the covering around the cutout to make sure it is sealed

down tight.

b) Install the rubber grommets and brass eyelets (supplied with

your radio system) into each aileron servo.

c) Install the control arms on the two aileron servos. The arms

should be at 90 degrees to the servo when the aileron control stick

on the transmitter is in neutral and the transmitter trims are in neu-

tral as well.

d) Before installing the aileron servos in the wing panels you

must attach a servo extension cord to the aileron servo wire. The

typical combined length required is approximately18”. A 6” exten-

sion chord will usually provide sufficient length. Plug the servo

plug into the extension cord and tape the plugs together for added

security.

e) Holding the wing panel with the wingtip UP, drop the end of

the extension chord into the servo mount cutout and then thru the

openings in the wing ribs, working it towards to the center end of

the wing panel. The plug on the end of the extension chord will

occasionally get hung up on the ribs, however by turning or gently

shaking the wing panel you can get it to fall through the openings

in the ribs, until it emerges at the end rib. Once you’ve got the

plug to the end rib, direct it through the round hole in the bottom

surface of the wing panel. By that time, the servo itself should be

next to the servo mount cutout and ready for mounting.

f) Fit the servo into the servo mount in the wing panel, (note

that the servo is positioned so that the servo arm is at the forward

end toward the wing leading edge). Take up any slack in the servo

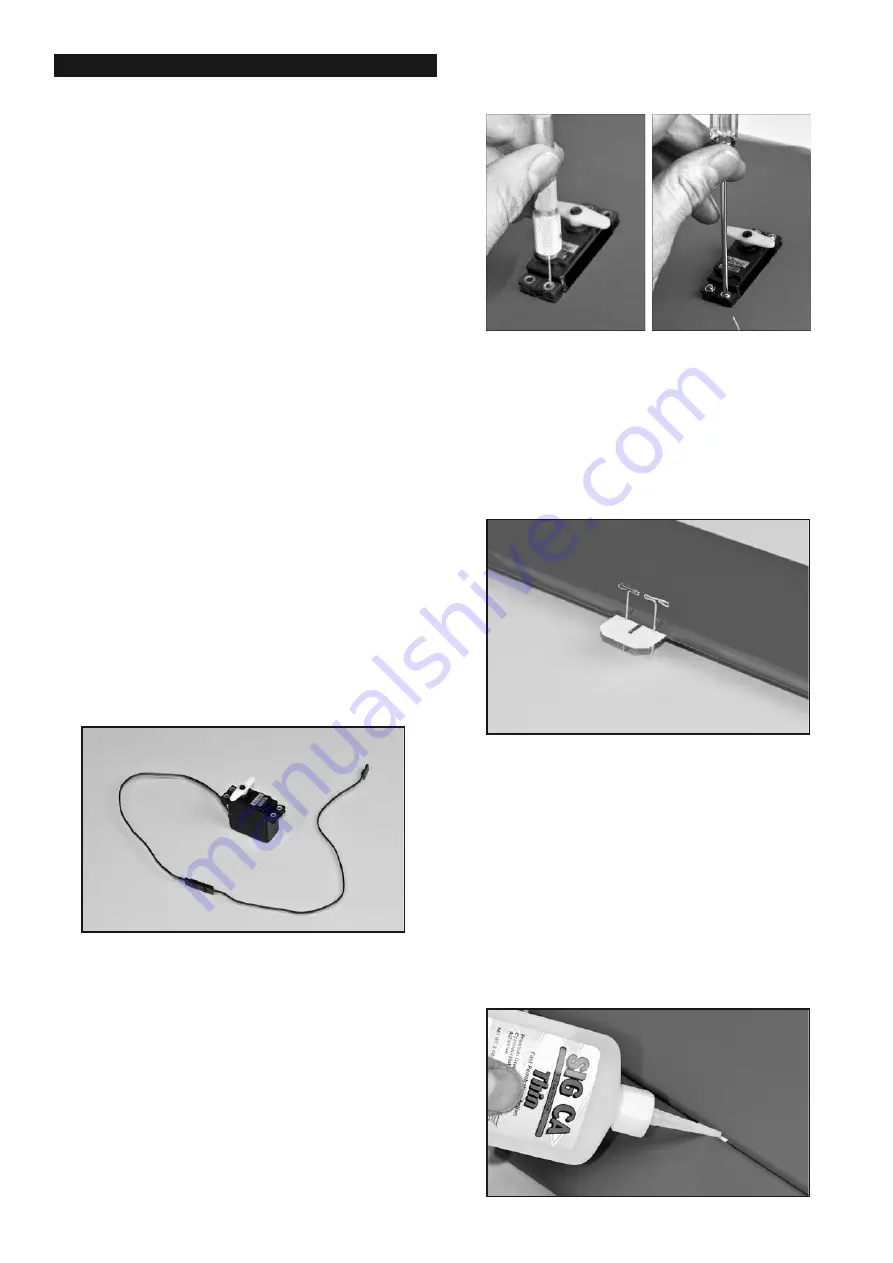

chord as you insert the servo in the mount. Use a pin vise and a

small drill bit to drill small pilot holes in the servo mount for the

servo mounting screws. Use the screws supplied with your radio

system to mount the servo in place on the servo mount. Repeat

this procedure to mount the servo in the opposite wing panel.

HINGING THE AILERONS

❑

2) Note that the CA Hinges are installed, but not yet glued, in

the ailerons and wing panels. The installation process for the

hinges is the same for all of the control surfaces on this model.

a) If you removed the ailerons and hinges from the wing panels

when you tightened the covering material, reinstall them now.

First insert the five CA Hinges into the slots in the aileron. Put

two pins in the center of each hinge, up against the leading edge

of the aileron, to keep the hinges centered during the next step.

b) Now carefully insert the exposed portion of the five hinges

into the trailing edge of the wing. You will find it easiest to slide

the hinges into the slots at angle, one hinge at a time, instead of

trying to push it straight onto all the hinges at once.

c) Adjust the aileron so that the tip of the aileron is flush with

the wing tip. The ailerons should be tight against the pins in the

hinges to minimize the gap between the wing and the aileron. The

aileron is now in the proper position for permanently gluing them

in place with thin CA glue.

d) Flex the aileron down and hold it in this position. Remove

the pins from one hinge and then carefully apply 3-4 drops of Thin

CA glue directly onto the hinge in the gap. You will notice that the

glue is quickly wicked into the slot as it penetrates both the wood

and the hinge. We suggest using a fine tipped applicator on the

glue bottle to better control the flow of glue.

5

WING ASSEMBLY