8

se the

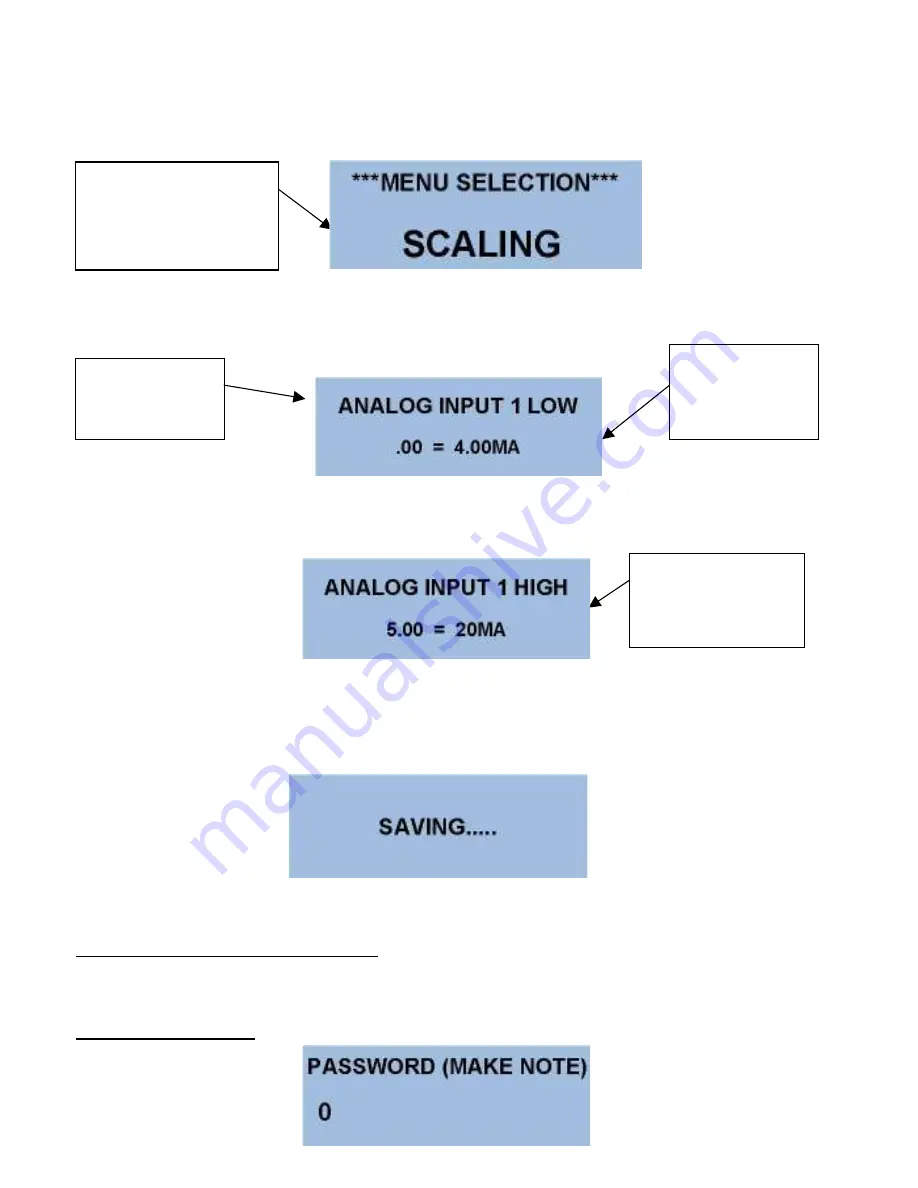

buttons to enter the preprogrammed password, then press

to advance to the Menu

Screens.

Use the

buttons to advance to the ‘Scaling’ screen.

Press

to advance through all input screens and when complete, the controller will save all changed

values and return to the Main Screen.

Use the

buttons to enter the displayed value for channel 1 low.

NOTE:

Numbers will

change faster

with the key held down.

Move to Screen 2

Press

to advance to channel 2 settings.

Continue with setting channels 2 – 8 in the same way as described.

And return to the Main Screen.

ADVANCE TO THE ‘SETUP’ MENU’

Setup screen provides ‘global’ parameters, which affect overall performance and operation.

PASSWORD SCREEN

Display shows

that a value of

4MA will

display .00

Shows that a value

of 5.00 will be

displayed with an

input of 20MA.

Show Channel 1

Input Low Value

Scaling screen allows

user programming of all

channels in engineering

units.

Summary of Contents for 700 PDL Series

Page 6: ...6...