BUILD-IN TOUCH TERMINAL

ETT 771

15.07.2020

Page 21

8

CAN Bus Setup

This section explains how to correctly configure the CAN bus. The following parameters

must first be set: Station number and data transfer rate.

8.1

CAN Bus Station Number

Each CAN bus station is assigned its own station number. With this station number, data

can be exchanged with other stations connected to the bus. In a CAN bus system however,

each station number can only be assigned once!

8.2

Number of CAN Bus Participants

The maximum number of participants on the CAN bus depends on the cable length, termi-

nation resistance, data transfer rate and the drivers used in the participants.

With a termination resistance of 120

, at least 100 participants are possible.

8.3

CAN Bus Data Transfer Rate

Various data transfer rates (baud rates) can be set on the CAN bus. The longer the bus line

is, the lower the data transfer rate that must be selected.

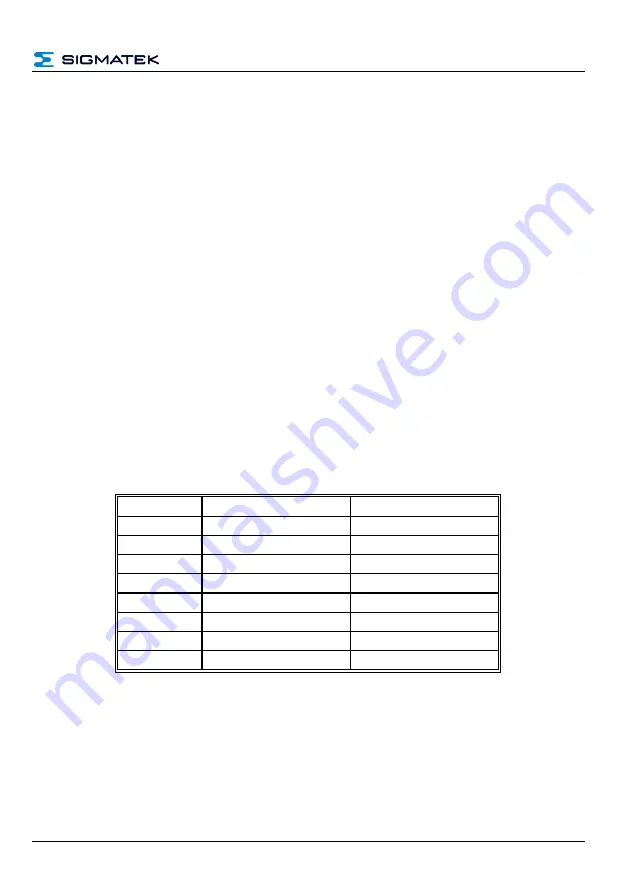

Value

Baud Rate

Maximum Length

0

615 kbit/s*

60 m

1

500 kBits/s

80 m

2

250 kBits/s

160 m

3

125 kBits/s

320 m

4

100 kBits/s

400 m

5

50 kbits/s

800 m

6

20 kbits/s

1200 m

7

1 Mbits/s

30 m

*only between devices with EDGE2 technology

These values apply to the following cable: 120

Twisted Pair.

Note: For the CAN bus protocol: 1 kbits/s = 1 kBaud