3

OPERATING INSTRUCTIONS

Wear safety glasses which conform to ANSI Standard

Z87.1 or EN 166.

Always position yourself to one side of the strap

while tensioning and sealing. Make sure all

bystanders are clear before proceeding. Maintain

proper footing and balance.

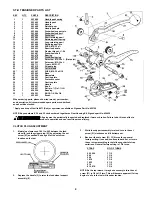

1.

Drape strap around package. Take-up slack, keeping

straps squarely in line. Hold hand tensioned strap in

position with left hand, grasp the tool in right hand,

squeeze handle to base, thus lifting feedwheel. Fully

insert both straps between feedwheel and gripper plug,

allowing lower strap to extend approximately 1" beyond

gripper plug, as shown. Position rear foot of tool on top

of straps.

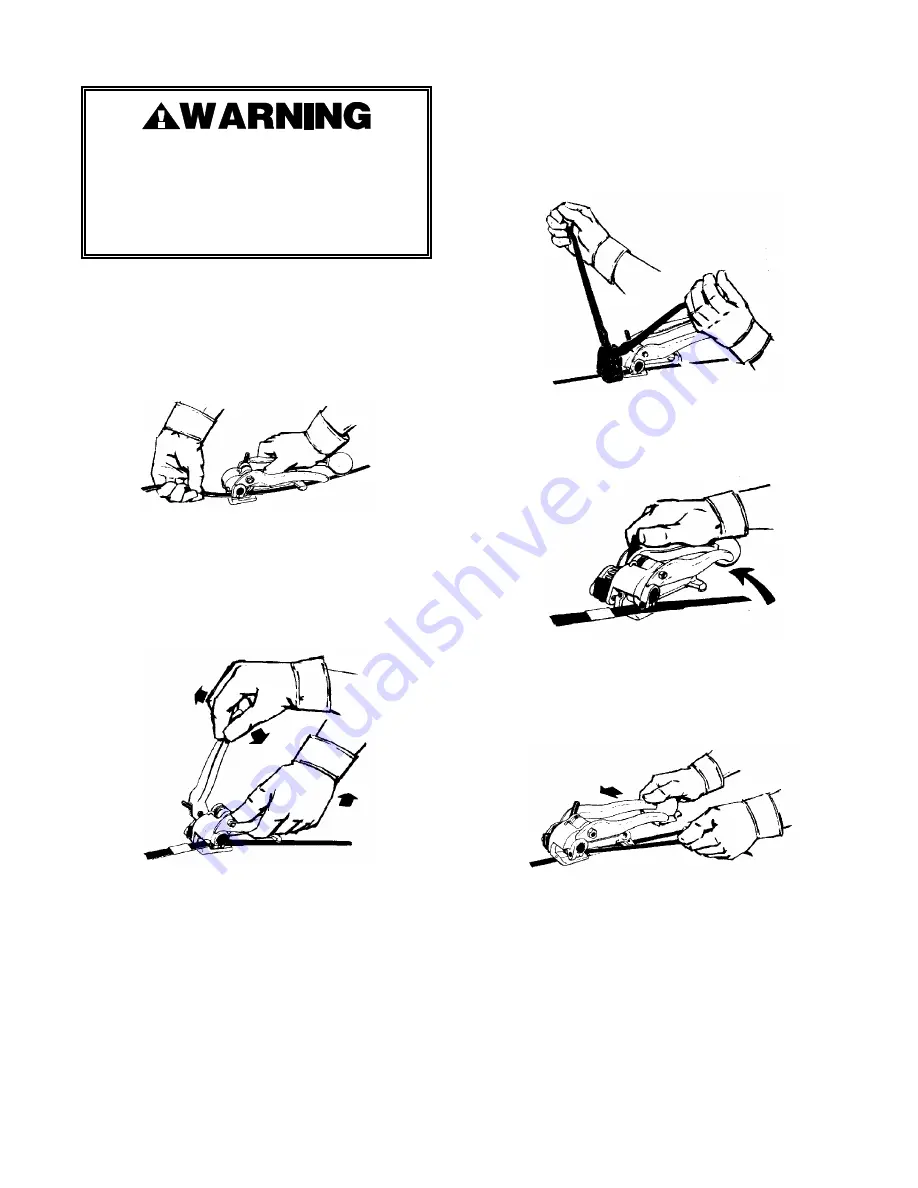

2.

Stand to one side of the strap line. Tension is obtained

through a continuous up and down motion with the

tensioning handle. At the same time, maintain a constant

upward pressure on the reaction handle, lifting the back

of the base slightly off the package. On initial downward

strokes, do not allow handle to press against base as this

will raise feedwheel and release tensioned strap. Snap

seal on strap directly in front of tool.

3.

Hold sealing tool at right angles to strap, resting it

squarely over seal. Seal the tensioned strap by bringing

sealer handles together as far as they will go.

4.

Return tensioning handle to rest on the tool by pressing

the handle pawl with thumb. Squeeze handle to base and

remove tool from strap by swinging rear foot out, as

illustrated.

5.

With left hand, pull top strap back and at an angle to the

left, holding taut. Place base of tool just ahead of seal,

cutter blade on the strap. Grasp knob of tensioning

handle and slide tool forward to cut the strap. Inspect the

joint to make sure it had been properly formed. Refer to

the sealing tool manual for details regarding the joint.