4

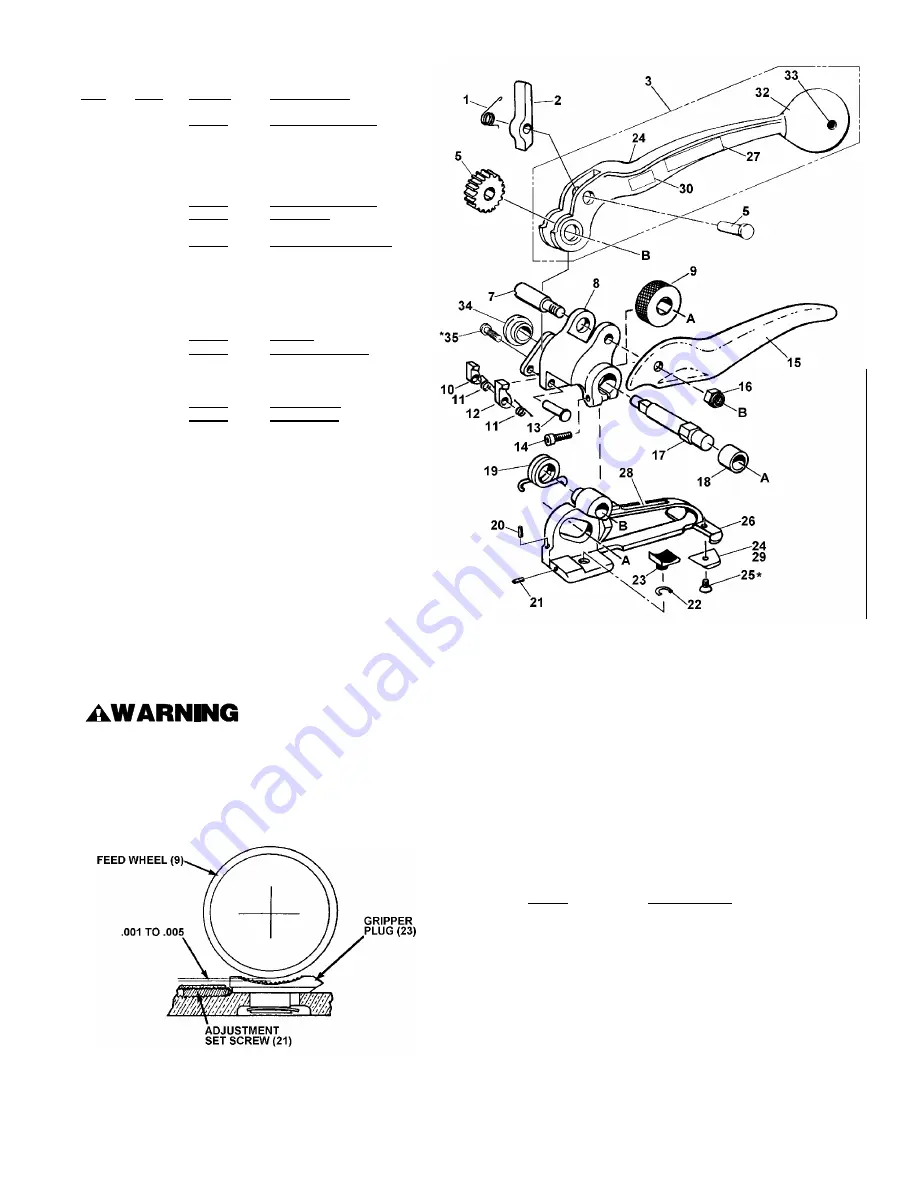

ST-D TENSIONER PARTS LIST

KEY

QTY.

PART #

DESCRIPTION

1

1

003489

Handle pawl spring

2

1

003492

Handle pawl

3

1

003493

Handle

5

1

003488

Ratchet gear

6

1

003494

Handle pawl pin

7

1

023964

Feedwheel support pin

8

1

003490

Feedwheel support

9

1

023954

Feedwheel

10

1

003485

Short retaining pawl

11

2

003483

Retaining pawl spring

12

1

003484

Long retaining pawl

13

1

003486

Retaining pawl pin

14

1

004502

SHCS, #10-32 x ¾

15

1

023953

Reaction handle

16

1

003868

Flexloc thin nut,

d

-24

17

1

003487

Feedwheel shaft

18

1

003478

Bearing

19

1

003479

Feedwheel spring

20

1

023957

Set screw, #10-32 x

e

(Flat point)

21

1

023965

Set screw, #10-32 x

e

22

1

020711

Truarc, #5101-37

23

1

023912

Gripper plug

24

1

023966

Cutter blade

25*

1

023967

FHSS, #10-32 x 5/16

26

1

023952

Base

27

1

183024

Nameplate

28

1

182997

Caution plate

29

1

098228

Protective cover

30

1

003133

Caution plate

31

1

003493

Handle

32

1

306927

Knob

33

1

010057

Roll pin, ¼D x 1-¾LG

34

1

424250

Bushing

35

1

424251

BHCS, 1/4-28 x 1/4

--

1

023963

Brush

When ordering parts, please show tool model, part number,

and description. All recommended spare parts are underlined

and should be stocked.

* Apply one drop of Loctite #271 (Red) or equivalent, available as Signode Part No. 422796.

NOTE: Keys numbers 8, 34 and 35 can be ordered together as Gear Housing Kit, Signode part No. 424436.

All parts must be periodically inspected and replaced if worn or broken. Failure to do this can affect a

product's operation and can result in personal injury.

CLUTCH PLUG ADJUSTMENT

1.

Maintain a clearance of .001 to .005 between the feed

wheel (9) and the gripper plug (23) by adjusting the set

screw (21) as needed. See page 9 for the set screw

location on the tool.

2.

Depress the handle (3) to raise the feed wheel support

assembly (8).

3.

While the support assembly is raised, turn in the set

screw (21) clockwise, until it bottoms out.

4.

Back out the set screw (21) 1 3/4 turns for a general

factory setting. If needed, continue to back out or turn in

the set screw according to the following chart of strap

variations. General factory setting is 1 3/4 turns.

STRAP

NO. OF TURNS

502, 504

1 1/2

506

1 3/4

508

2 1/2

1816

1 3/4

1822

2 1/2

814

1 1/2

816, 818

1 3/4

NOTE: As the tool wears, it may be necessary to turn the set

screw (21) in 1/4 to 1/2 turn. This will become apparent if strap

begins to slip in the tool while under tension.