04.20

11

Josef Kihlberg B560

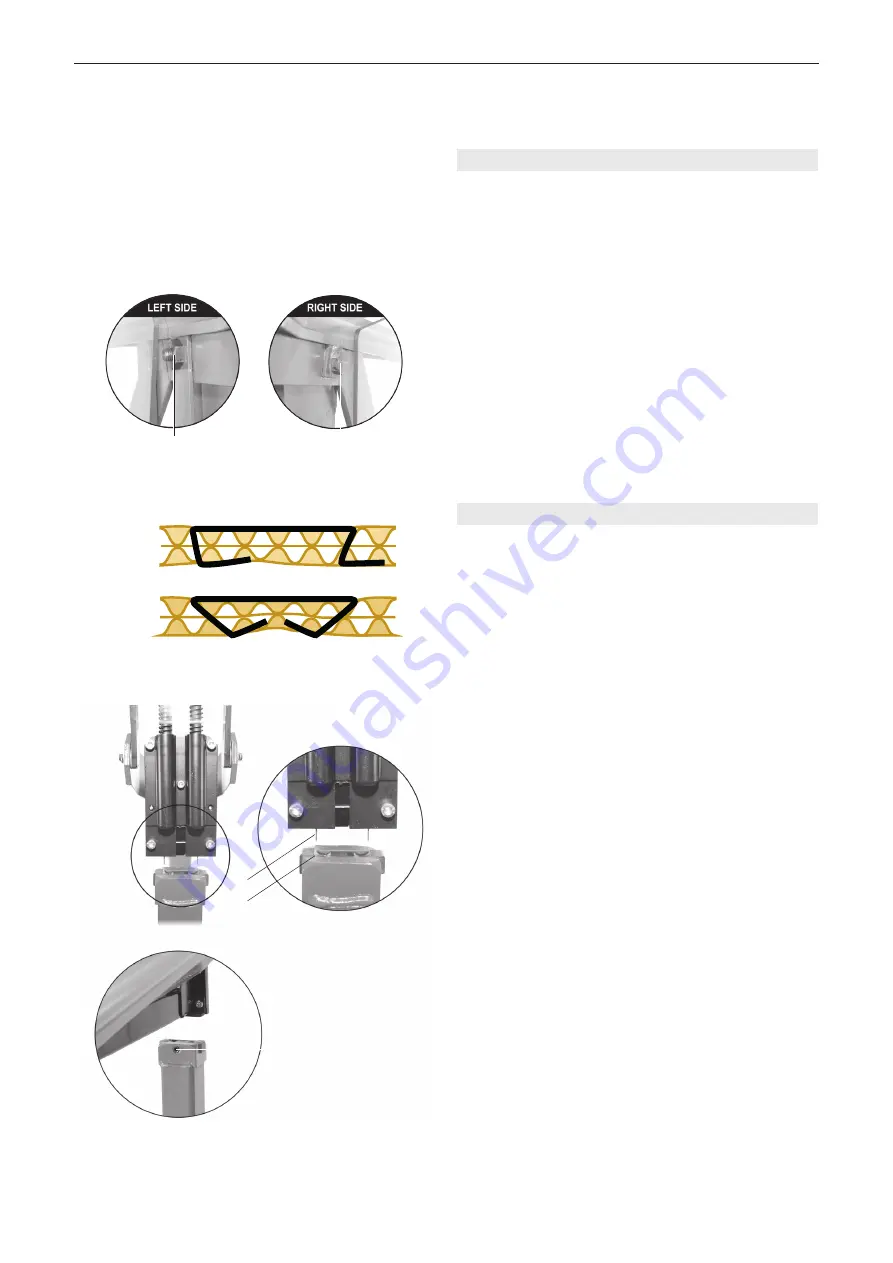

7.5 ADJUST STAPLE CLINCH

Each bottom stapler is tested carefully before delivery.

Following rough treatment during transport a screw

may become loosened and the anvil may therefore

have to be adjusted. Incorrect stapling may occur

(Fig. 13/1).

– Press down a staple (Fig. 14/1) by hand until the

staple legs are visible or insert a single staple into

the canal.

– Move the staple head down towards the anvil (Fig.

14/2) and check that the staple legs hit the anvil sym-

metrically.

– If necessary, loosen the screw (Fig. 14/3) and cen-

tre the anvil to the staple. Remember to tighten the

screw after adjustment.

– Make a test stapling in a piece of cardboard. If the

anvil is correctly adjusted, the clinch should be as

shown in (Fig. 13/2).

7.4 ADJUSTMENT OF STAPLING HEAD BEARING

Upon delivery, the stapling head bearing is tight but

easily movable. After being in use for a while, the be-

aring will have become worn and must be readjusted

as follows:

– Loosen nut (Fig. 12/1) and screw (Fig. 12/2).

– Tighten screw (Fig. 12/2) to obtain just enough play.

– Lock with nut (Fig. 12/1).

Fig. 13

To short

Correct

To long staple

Fel

2

To short

Correct

To long staple

Fel

1

Fig. 14

1

2

3

Fig. 12

1

2