-2-

BACKPLATE

BACKPLATE

SIGN

HOUSING

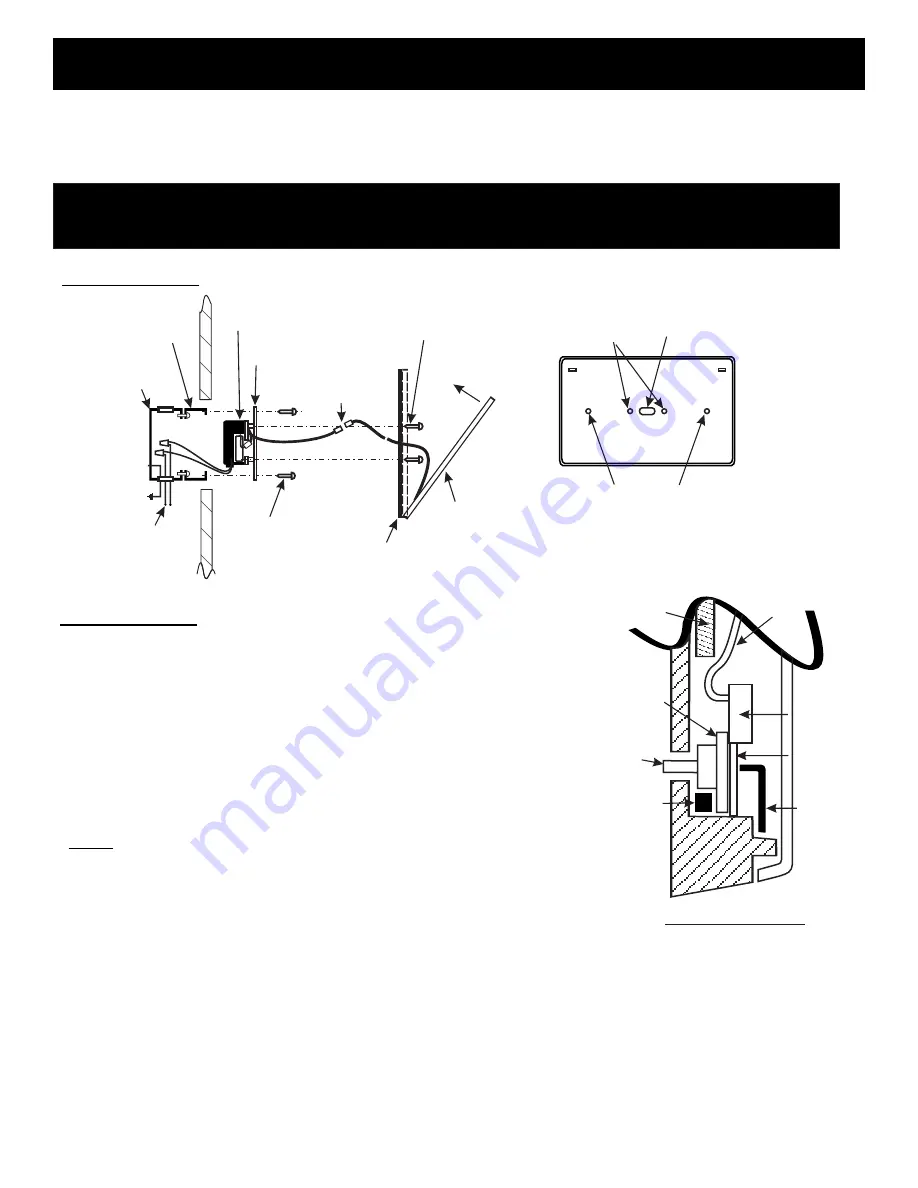

ALL INSTALLATIONS REQUIRE STANDARD TYPE 4" x 4" SQ x 2 1/8" DEEP J- BOX.

SET ADAPTOR PLATE ¼"- 3/8" BELOW FINISHED PANEL SURFACE

Before installing or connecting any primary power wiring,

DISCONNECT MAIN POWER SUPPLY AT THE CIRCUIT BREAKER OR FUSE.

WALL MOUNT

WALL MOUNT

1. Install J-Box 1/8"-1/4" below finished panel surface. Connect Power Module AC wiring to

building supply in J-Box, using wire nuts or connectors supplied.

BATTERY MODELS: BLACK: 120 277 VAC WHITE: Common

AC MODELS: Non- Polarized Line in.

2. Route wire nuts to side of J-box, insert Power Module into box and secure with 2 #8-32 box

screws.

NOTE: Power module orientation is universal, position as required to clear connectors

and wire nuts in J-box.

3. Remove back plate from sign assembly by inserting pin (small screwdriver or allen key)

into 2 release holes in top edge, press down to release clips and hinge cover away from

housing.

4. Support backplate on raised flat surface and knock out oval opening

in center.

NOTE: Remove any sharp edges around opening by file or sharp metal blade. Drill 3/16"

diameter holes at locations noted above. For additional support drill out 2 additional 3/16"

dia holes at left and right sides on center. Locate back plate in position on wall and mark

support holes; install wall anchors for support screws.

5. For battery backup models, connect 2-pin polarized battery plug.

6. Run LED lamp plug through backplate. Attach back cover to j-box with 2 #8-32 screws

supplied. Install and tighten 2 support screws. DO NOT OVERTIGHTEN.

7. Insert 2 tabs on base of sign assembly into slots in base of back cover. Connect LED lamp

plug.

8. Hinge sign assembly into position and snap closed.

To remove signs, repeat step 3.

W

ALL

POWER

MODULE

ADAPTOR

PLATE

BACKPLATE MT. SCREWS

#8-32 SELECT LENGTH

1/2" - 3/4"

REMOVE

K.O. FOR WIRING

DRILL OUT 3/16" DIA

IN TWO PLACES TO

MATCH

J-BOX LOCATION

DRILL 3/16" IN TWO PLACES

FOR ADDITIONAL WALL MT.

SUPPORTS

USING SCREW ANCHORS

1 1/2" SQ.

EXTENSION

AC POWER

INPUT

120/277 VAC

POWER MODULE

MOUNT SCREWS

#8-32 (2 REQD)

POLARIZED

LED LAMP

PLUG

GRD

J- BOX

4" x 4"

x 2 1/8"

LOWER

BRACKET

SPACER

TEST

PANEL

DIFFUSER

LENS

TEST SWITCH

AND LED

INSULATOR

PLUG

CONNECTOR

WIRING TO

POWER

SUPPLY

TEST PANEL ASSEMBLY

Series RPROBB & RPROAC

Rapier Open Face Die Cast LED System

Battery Backup & AC Models

03.15.03