3.5 Power On

• Keep fingers away from the platen when the cutting

plotter is in operation.

• Keep loose clothing, hair, and any other items away from the grid

drum when the cutting plotter is in operation.

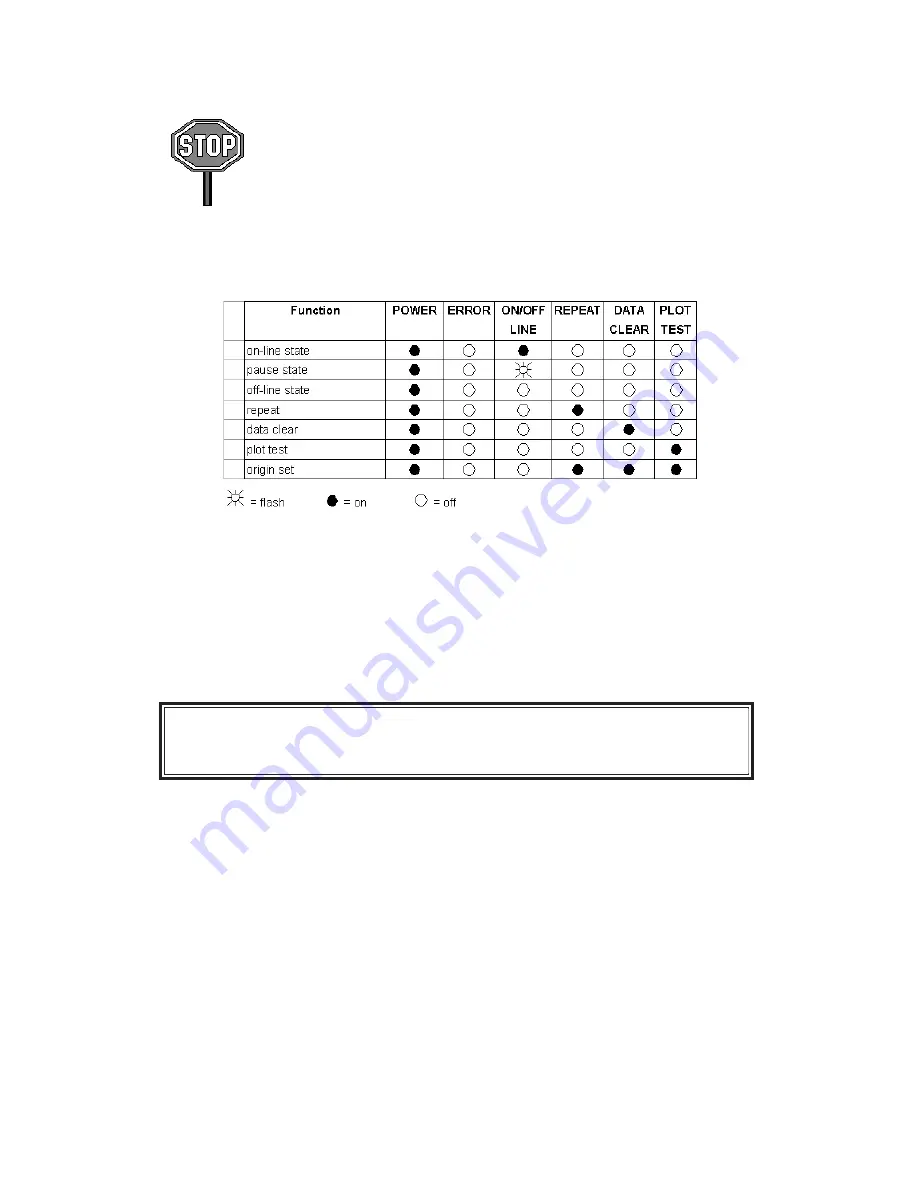

Turn on the power on the left side of the cutting plotter and the POWER LED will light up.

Notice: It will take about 10 sec. to initialize the machine; then the cutting plotter will be

ready to receive data from a computer. Refer to the following chart to understand what

represented by each light on the control panel.

3-8

3.6 ON/OFF LINE Key

**On line

When the machine is under the “

ON LINE

” condition, the ON/OFF LINE LED lights up.

The cutting plotter is ready to receive data from the host computer. At this moment, only

“PAUSE” and “ON/OFF LINE” keys are valid.

**Change the setting value

1. Press the

PAUSE key.

Then switch the DIP to

change the value settings.

2. Press the

ON/OFF LINE key

to valid the new settings and to

continue cutting.

**Terminate the cutting & clear the data in the buffer

1. Press the

ON/OFF LINE

or

PAUSE

key

2. Then press the

DATA CLEAR

key

**Off - line

When the machine is in

“OFF LINE” mode

, the

ON/OFF LED

doesn’t light up. At this

moment, you can switch the DIP settings, make a plot test to adjust the cutting pressure

and set a new origin. Pressing the button again will let the cutting plotter switch back to

“ON LINE” condition, and resume the suspended operation. However, there might be

some data loss during this interruption.

3.7 PAUSE Key

The purpose of the “

PAUSE

” key is to temporarily terminate the motion of the cutting

plotter after it starts cutting. At this moment, the

ON/OFF LINE LED

is flashing; you can

change the DIP Switches settings and the cutting force. It will resume cutting after the

ON/OFF LINE

key is pressed, to return the machine back to on-line status.

Note :

The parameters of the DIP Switch can not be changed while cutting unless you press

the “

PAUSE

” key. After pressing the “

PAUSE

” key, you can change the settings

.