Instruction Manual OilGuard 2 W

Mounting

24

14809E/2

The following procedure describes how to mount the sample connections on the

OilGuard 2 W:

WORKSTEP

ADDITIONAL INFO / IMAGES

1.

Remove the optics unit according to

Section 9.1.1 and fasten on the docking sta-

tion.

Warning! UV radiation.

Use UV goggles and gloves.

2.

Fasten the inlet hose on the inlet pipe

(Figure 3, pos. 1).

3.

Fasten the outlet hose on the outlet pipe

(Figure 3, pos. 7).

When doing so, press the outlet cone

(Figure 3, pos. 5) downward by hand so that

the outlet pipe (Figure 3, pos. 7) is not pressed

into the measuring cell space.

Flooding of the measuring cell

due to improper mounting of the

outlet hose.

The outlet hose must be fastened

so that the holes on the side are

not covered (flood protection).

Section 4.4.1

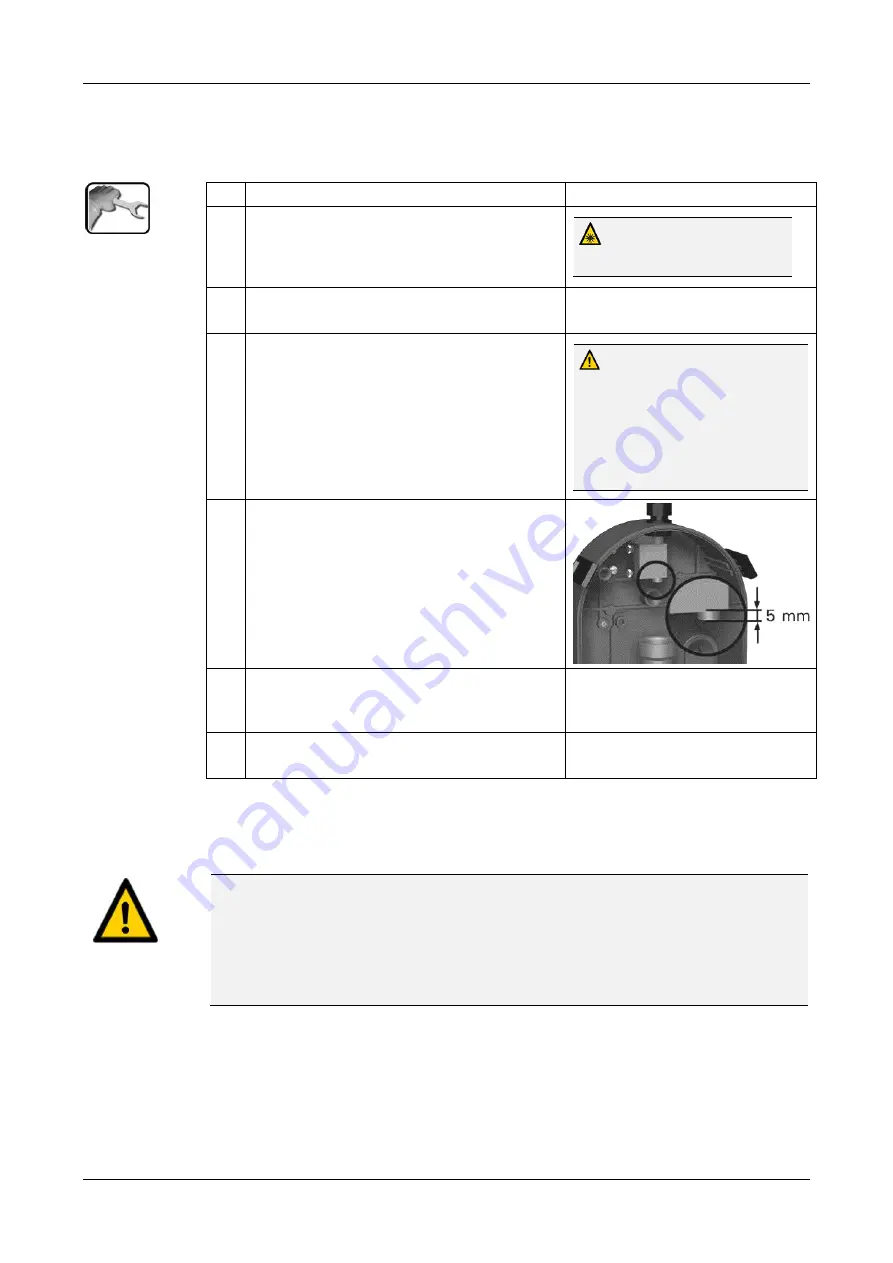

4.

Check to ensure the inlet pipe (Figure 3,

pos. 1) projects 5 mm out of the holder.

5.

Check to ensure the outlet cone (Figure 3, pos.

5) is in contact with the conduit gland

(Figure 3, pos. 6).

6.

Place the optics unit back on the measuring

cell unit and lock with the four mounting clips.

4.5

Mounting the optional accessories

4.5.1

General information on the optional accessories

CAUTION!

Note the following when mounting the optional accessories:

All hose connections must be secured with hose clamps. The connections should be

checked about two weeks after installation to ensure that no air can be pulled in.

A minimum flow of 1 l/min. must be guaranteed on the overflow of the level control.

The dimensions on the dimension sheets must be adhered to (course and radii of the

hoses, spacing etc.).

4.5.2

Mounting the level control

Mounting of the level control is made according to the dimension sheets

OILGUARD 2 W/1-MB

.