5-23

Tro

ub

le

sh

oo

tin

g

5

¢

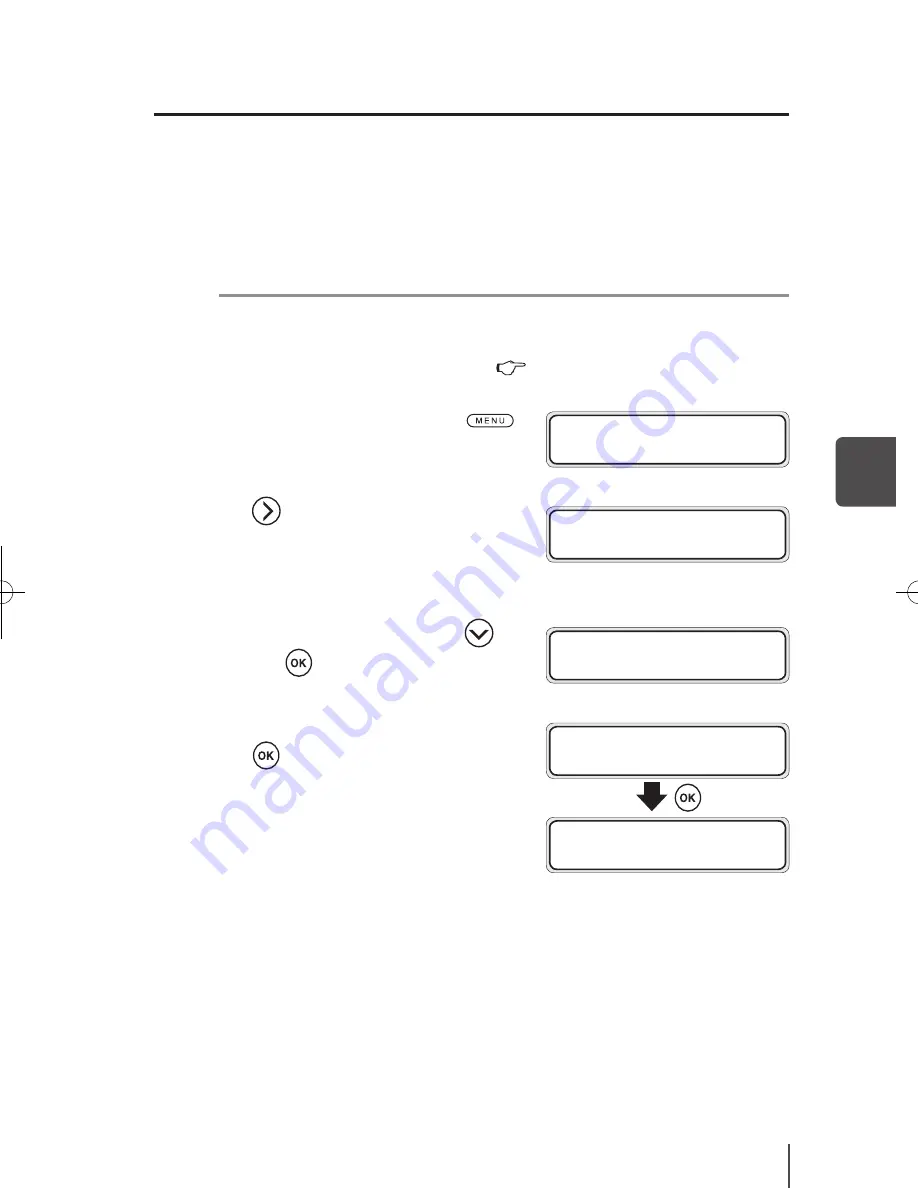

Cleaning of Print head surface

When clogged nozzles is not solved after performing print head cleaning, the

print head surface may be contaminating the print. Clean using the following

procedure.

Note

-

As many fine nozzles are arranged precisely on the Print head surface, clean-

ing may risk to damage the Print head. Therefore, follow the procedure in

[How to get good image quality ] (

P.5-15), and perform the cleaning.

1

Set the printer to the offline. Press

key to display the PH.MAIN MENU.

2

Press

key to enter in the PH.MAIN

MENU. Then, the cap cleaning menu is

displayed.

3

Select [RESEAT PRINTHEAD] using

key

and press

key.

4

When the confirmation menu is displayed,

press

key.

Then, the carriage moves.

5

Open the Front cover and then the Main-

tenance cover.

h

REWIND

FORM FEED

i

f

PH.REC

PH.MAIN

g

#CAP CLEANING

>

#RESEAT PRINTHEAD

>

#RESEAT PRINTHEAD

*

OK ?

CARRIAGE MOVING

PLEASE WAIT

q

How to get good image quality

IP-5610取説_E.indb 23

09.4.3 3:15:54 PM