170

171

Troubleshooting

Troubleshooting

Printing is slow. During print, print heads are capped frequently.

Items to be checked

Corrective measures

High-temperature environment

If the printer temperature is 40°C or more, the printer prints at a lower speed. Set the

ambient temperature to 20 to 25°C (recommended temperature), and leave the printer

for one hour or more before starting the print.

Computer specifications

Remove any additional devices connected via USB.

Computer specifications

Connect the printer to a computer satisfying the recommended operational

environment for your RIP software. For the recommended operational environment,

contact the manufacturer of your RIP software.

Computer other processing

Terminate other software applications, for example, anti-virus software.

You cannot understand the current operation panel display language.

Items to be checked

Corrective measures

Language setting

Start with the printer turned off. On the operation panel, press the

MENU

key and hold

it down. While holding the

MENU

key down, press the

POWER

switch and hold it down.

Continue to hold down both keys. Then the language selection menu appears on the

operation panel display. Highlight your preferred language with the

Up

and

Down

keys,

then press the

OK

key.

Clogged nozzles cannot be cleared.

Items to be checked

Corrective measures

Damaged media edges

If the media is damaged with some sections coming out from the edge guards, it may

contact the heads nozzle surfaces and cause nozzles to clog.

Cut any damaged sections with a pair of scissors or a cutter before installing the media.

Adhesive coming off the vinyl causing

the media to rise

Feed the media to beyond the risen area.

Media wrinkling and rising

Set the suction fan level to HIGH.

Decrease the printheater temperature.

Media adhering to the platen

Set the suction fan level to LOW or OFF to make it advance again.

Setting media advance mode to BACK & FWD LOW may also prevent the media from

adhering to the platen.

Daily maintenance

Check that the daily maintenance has been executed and that it is performed

periodically.

How to clear media jams

1

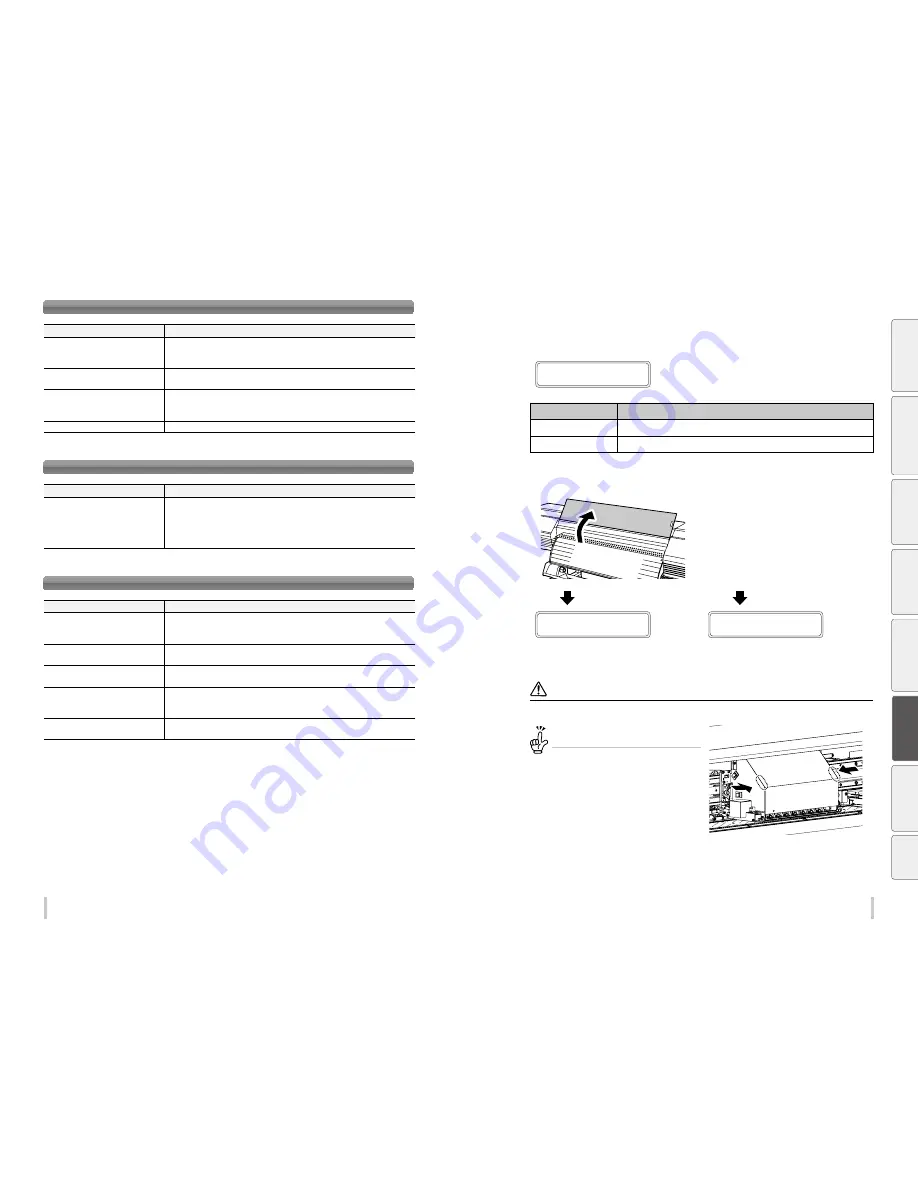

MEDIA JAM ERROR

1

LIFT THE LEVER

The message to the left appears.

X: Media jam type

Meaning

1: Media jam 1

A jam on the carriage is preventing the printer from operating correctly.

2: Media jam 2

A media not supported is used. The media cannot be detected correctly.

2

Lift the pressure roller lever and open the

front cover.

When you lift the lever

OPEN COVERS AND

REMOVE MEDIA

When you open the cover

LIFT THE LEVER AND

REMOVE MEDIA

3

Clear the media jam, make sure that no obstruction is left in the carriage path and the media

feed path, and then close the front cover.

Note

In case of roll media, rewind some of the media.

To manually move the carriage...

If the carriage must be moved manually, slide the

carriage by softly pressing locations indicated with

the arrows.

Be

fo

re

p

rin

tin

g

Lo

adi

ng

the

m

edi

a

A

dj

us

tm

ent

M

ai

nt

enan

ce

A

dv

an

ce

d

op

er

ati

on

s

Trou

ble

sh

oo

tin

g

M

enu

tr

ee

Ap

pe

nd

ix

Summary of Contents for IP-6620

Page 112: ...222 ...