182

183

Troubleshooting

Troubleshooting

Solve print quality issues

This section contains hints to enhance the print quality with the printer based on several symptoms.

Take appropriate actions according to the symptoms.

When several actions are described, they are arranged in order of effectiveness. Therefore, you are recommended

to take the actions starting from the top and confirm the effect on the improvement. (Note that all the described

actions are not always necessary to solve the problem.)

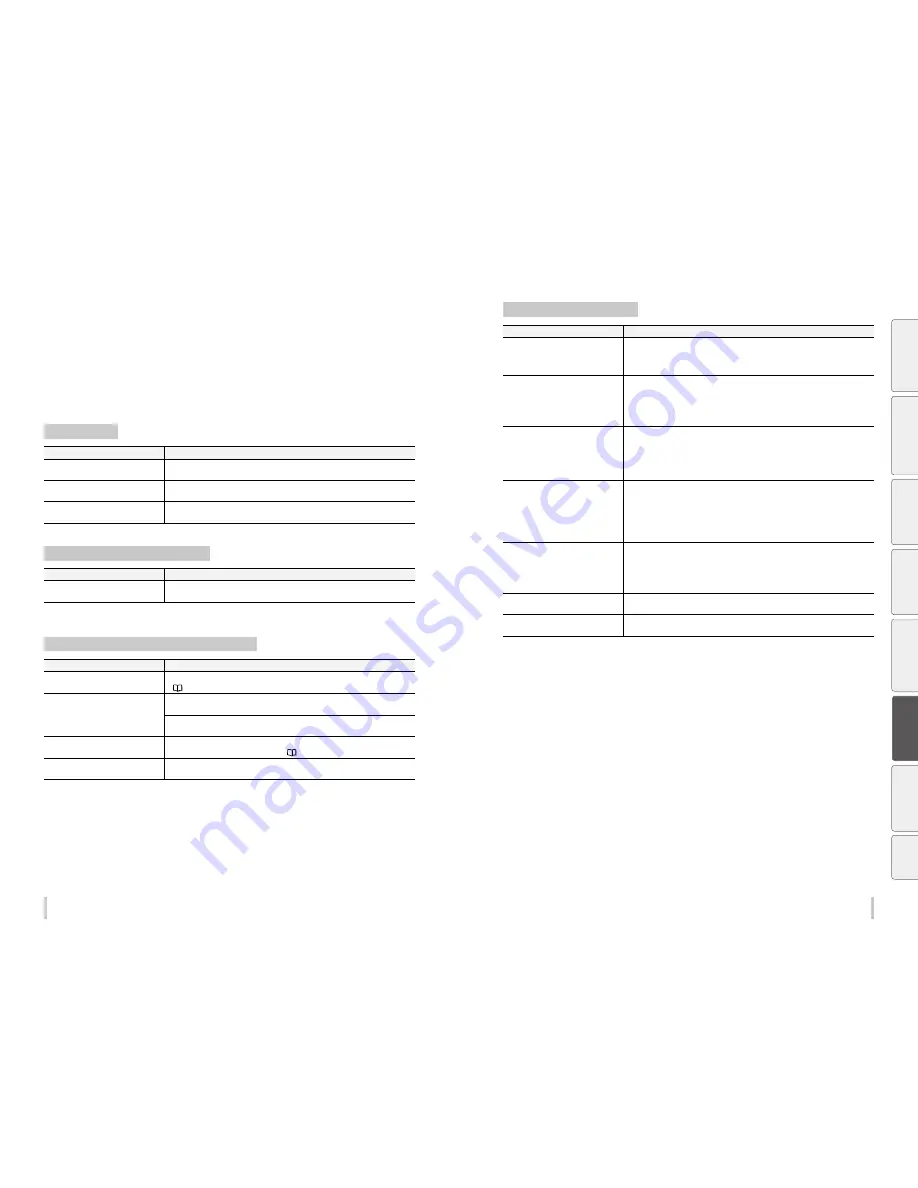

The print is pale.

Cause

Solution

The density setting is not correct.

Set density to HIGH DENSITY if high density printing is required, such as when using

backlit banner media.

The operating environment is outside

the specification of the Printer.

Raise the ambient temperature to 15ºC or more (20 to 25ºC recommended) to warm the

printer adequately.

Media is not selected properly.

Check the media selection.

The printout is blurred or grains appear.

Cause

Solution

The bidirectional and media advance

adjustment values are not correct.

(1) Perform bidirectional adjustment and media advance adjustment again.

(2) If automatic adjustment has been performed, perform manual adjustment.

Missing dots are found at the beginning of printing.

Cause

Solution

Outside the operating temperature/

humidity range

Use the printer within the operating temperature/humidity range.

(

page 22

)

Obstructions in the nozzle surface

Check the platen, the media edge guards, the capping unit, the wiper blade, the

pressure roller, and the head guards, and remove any foreign matter.

Lint or paper fibers coming from a damaged media may touch the print heads, which

may cause missing dots. Replace the media with a media with no lint or paper fibers.

The media entered into contact with the

nozzle surfaces.

Perform normal cleaning.

If the problem persists, perform the action

page 179

.

Cleaning did not finish normally.

Perform the daily maintenance.

Clean the caps.

The media is curled or wrinkled.

Cause

Solution

Outside the operating temperature/

humidity range

(1) Use the printer within the operating temperature/humidity range.

* Note that some media may wrinkles even within the operating temperature and

humidity range.

(2) Use proven media.

The media storage conditions are not the

same as the printer operating conditions.

The difference between the media storage conditions and the printer operating

conditions may cause the media to curl or wrinkle. To prevent this, after carrying the

media from storage to the operation area, leave the media for while time in the new

environment before printing.

* The time depends on the media type and the storage conditions.

The media was not installed properly.

Check that the media was installed properly in the conditions below.

- The installed media is installed parallel to the printer.

- The operation panel shows the media type correctly.

- The media winding mode is optimal for the installed media.

- Check that the leading of the media output from the printer is installed straight to the

TUR unit paper tube.

The media wrinkled because of the

heater temperatures.

(1) If the media wrinkles while the printer is warmed by the heaters, install the media

only after the printer is warmed up by the heaters.

(2) Change the heater temperature. Increase or decrease all three heaters by 5°C.*

1

(3) Use proven media.

(4) If the media is still wrinkle, feed the media until you reach a portion without wrinkles.

(5) If the media wrinkles between each print job, change the media advance mode.

The media is curled.

(1) Do not use media curled in the vertical direction direction (vertical to the media).

(2) Do not use media curled in the horizontal direction (from the right edge to left

edge). The is so curled that the media edge guards and the suction fan cannot flat

the media.

(3) Use proven media.

Set the suction fan parameter of the

preset to LOW.

Set the suction fan parameter of the preset to a stronger setting.

Wrinkles caused by media advance

(1) Remove the media and install it again.

(2) Use proven media.

*1 When the heaters temperatures are changed, adjust the media advance adjustment value again.

Be

fo

re

p

rin

tin

g

Lo

adi

ng

the

m

edi

a

A

dj

us

tm

ent

M

ai

nt

enan

ce

A

dv

an

ce

d

op

er

ati

on

s

Trou

ble

sh

oo

tin

g

M

enu

tr

ee

Ap

pe

nd

ix

Summary of Contents for IP-6620

Page 112: ...222 ...