188

189

Troubleshooting

Troubleshooting

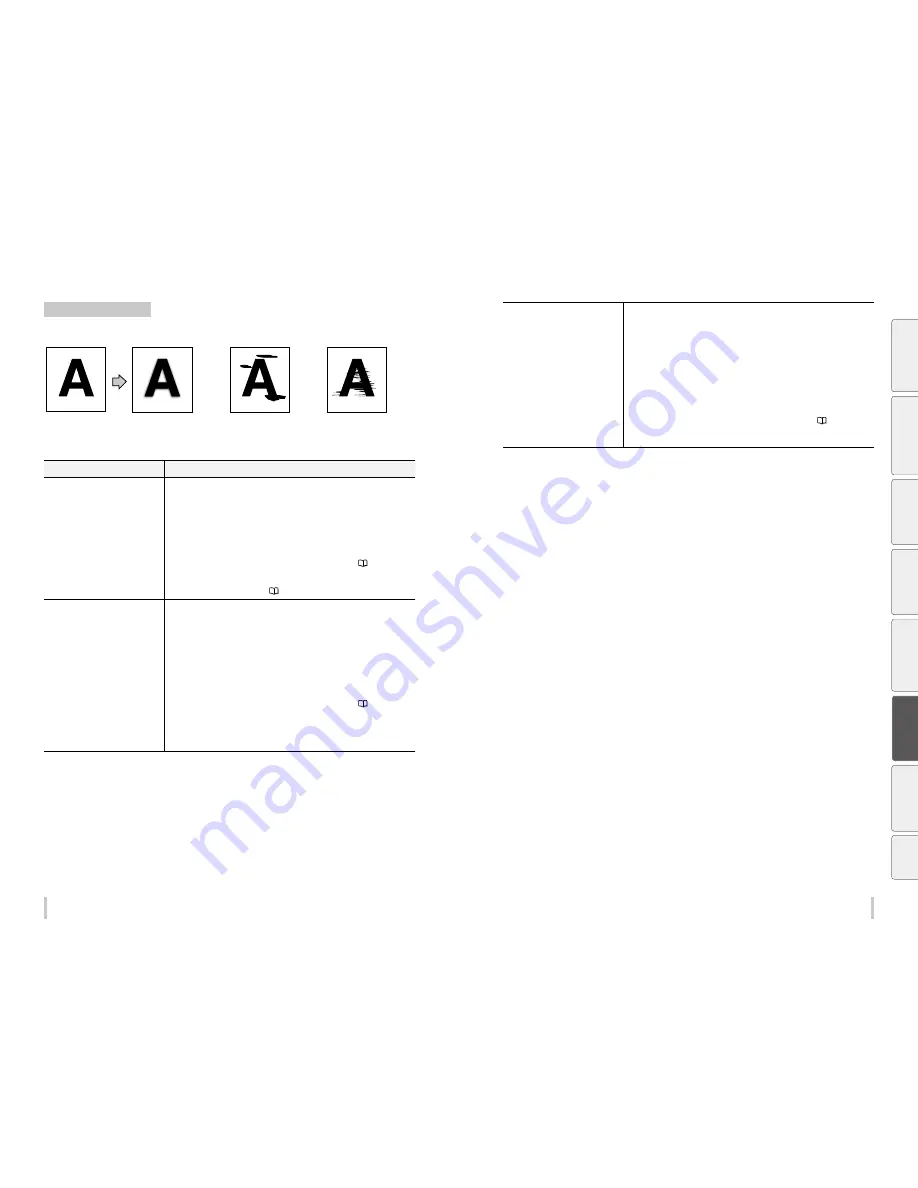

The printout is not clean.

[Cause]

The ink is improperly sprayed

from the print head.

[Cause]

The ink is drooling.

[Cause]

The print head is scratched by

media.

Basic image

[Symptom A]

[Symptom B]

[Symptom C]

Cause

Solution

[Symptom A]

The ink is improperly ejected from the

print heads.

(1) Use the printer within the operating temperature/humidity range.

(2) Perform the daily maintenance.

* Be sure to clean the head guard, edge guards, carriage bottom surface, and the right

and left sides of the top of the print heads.

(3) Perform print head cleaning (STRONG).

(4) Change to a more suitable print mode, or set the carriage speed to SLOW.

*

1

*

2

*

3

(5) Perform SET CAP FOR CLNG.

(6) Clean the print heads surfaces with print sheet mount cleaning (

page 97

).

(7) If the print heads height setting is set to high, set it to normal. *

4

* If problems occur with the media used when the print heads height setting is set to

normal, set it to another option. (

page 132

)

[Symptom B]

The ink dribbles.

(1) Use the printer within the operating temperature/humidity range.

(2) Check for obstructions such as media lint or ink clot in the nozzle scanning path

including the platen surface, and remove them.

(3) If the media is curled or wrinkled, solve the problem by referring to the description

on the problem, The media is curled or wrinkled.

(4) Perform the daily maintenance.

* Do not forget to clean the head guard and edge guards.

* Be sure to perform print head cleaning.

* Be sure to clean the caps.

(5) Perform SET CAP FOR CLNG.

(6) Clean the print heads surfaces with print sheet mount cleaning (

page 97

).

(7) With media that easily creates static electricity, the static electricity may cause the

ink to dribble. With such media, set the ionizer to ON. *1

(8) With some banner media, light media edges may touches the print heads, which

may cause the ink to dribble.

[Symptom C]

The print heads are scratched by the

media.

(1) Check that the media was installed properly in the conditions below.

- The installed media is installed parallel to the printer.

- The operation panel shows the media type correctly.

- The media winding mode is optimal for the installed media.

- If the media is curled or wrinkled, see the description on the problem, The media is

curled or wrinkled.

(2) Check for obstructions such as media lint or ink clot in the nozzle scanning path

including the platen surface, and remove them.

(3) Perform the daily maintenance.

* Do not forget to clean the head guard and edge guards.

* Be sure to perform print head cleaning.

(4) Perform SET CAP FOR CLNG.

(5) Clean the print heads surfaces with print sheet mount cleaning (

page 97

).

(6) Set the suction fan parameter of the preset to a stronger setting. *

1

(7) If the ionizer is set to ON, set it OFF.

*1 Adjust the media advance adjustment value again.

*2 Note that the print speed differs depending on the mode selected.

*3 Be sure to adjust the bidirectional adjustment value again after changing the carriage speed.

*4 Adjust the bidirectional print positions.

Be

fo

re

p

rin

tin

g

Lo

adi

ng

the

m

edi

a

A

dj

us

tm

ent

M

ai

nt

enan

ce

A

dv

an

ce

d

op

er

ati

on

s

Trou

ble

sh

oo

tin

g

M

enu

tr

ee

Ap

pe

nd

ix

Summary of Contents for IP-6620

Page 112: ...222 ...