4-3

Chapter 4 Basic Menu Operation

Offline menu operation

Press the

key to enter the offline mode.

If data remains, some menus may not be displayed though key operation

is available.

Select the menu group using the

and

keys.

To enter each menu, press the

key.

If any disabled key is pressed, a buzzer sounds.

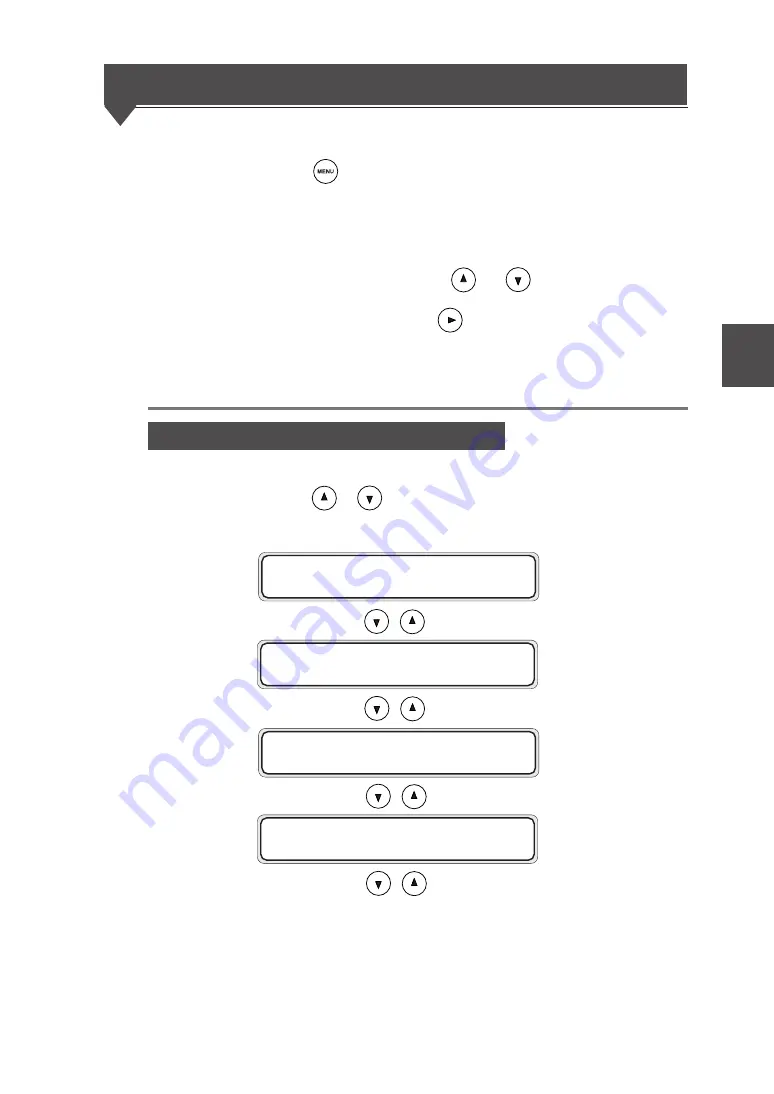

Switching the menu on the same hierarchy

Press the

or

key to switch the menu within the same hierarchy.

An example of the setup menu group is shown below:

S E T U P

# P O R T 1 _ H P G L

S E T U P

# P O R T 1 _ D S C A N

S E T U P

# P O R T 1 _ T I F F

S E T U P

# P O R T 1 _ C A L S

Summary of Contents for LP-1010

Page 2: ......

Page 4: ......

Page 24: ......

Page 108: ......

Page 118: ...4 10 Exiting the setting Press the key to return to the online condition ...

Page 166: ...8 4 Sample of print ...

Page 172: ...8 10 ENGINE LOG Prints the engine information Sample of print ...

Page 180: ......

Page 184: ......

Page 267: ...Appendix 14 RESET MENU SYSTEM RESET PORT RESET PORT1 M E N U R E S E T ...

Page 290: ......