MAINTENANCE

ATTENTION: for repairs or replacement of parts for maintenance, the ‘CE’ mark is guaranteed only if original spare parts pro-

vided by the manufacturer are used.

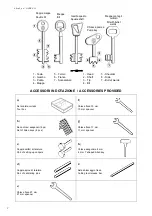

Although our key-cutting machines do not require special maintenance, it is advisable to check and, if necessary, replace the

parts subject to wear, such as: cutting tool, tracer point, transmission belt and brush, if applicable.

Replacement:

the operations are simple and can be carried out by the operator. The removable parts are so designed as to exclude the pos-

sibility of their being re-assembled or installed wrongly or dangerously.

Cleaning:

keep the carriage and clamps free of chippings from the cutting operations by cleaning with a dry brush.

WARNING! DO NOT

USE COMPRESSED AIR.

ATTENTION: to keep the machine well maintained we recommend using protective oil, e.g. WD40 or similar, applied to the

burnished mechanical parts. This prevents oxidation of the parts in question (clamps, guides, carriages, etc.).

Before starting any type of maintenance read the instructions below:

•

never carry out maintenance or servicing with the machine in motion

•

always remove the mains plug

•

use original spare parts

DISPOSAL

For correct disposal please refer to current standards.

INFORMATION FOR USERS OF PROFESSIONAL EQUIPMENT

From "Actuation of Directive 2012/19/EU regarding Waste Electrical and Electronic Equipment

(WEEE)"

The symbol of a crossed waste bin found on equipment or its packing indicates that at the end of the product’s useful life it

must be collected separately from other waste so that it can be properly treated and recycled.

In particular, separate collection of this professional equipment when no longer in use is organised and managed:

a) directly by the user when the equipment was placed on the market before 31 December 2010 and the user personally

decides to eliminate it without replacing it with new equivalent equipment designed for the same use;

b) by the manufacturer, that is to say the subject which was the first to introduce and market new equipment that replaces

previous equipment, when the user decides to eliminate equipment placed on the market before 31 December 2010

at the end of its useful life and replace it with an equivalent product designed for the same use. In this latter case the

user may ask the manufacturer to collect the existing equipment;

c) by the manufacturer, that is to say the subject which was the first to introduce and market new equipment that replaces

previous equipment, if it was placed on the market after 31 December 2010;

Suitable separate collection for the purpose of forwarding discarded equipment for recycling, treatment or disposal in an envi-

ronmentally friendly way helps to avoid possible negative effects on the environment and human health and encourages re-use

and/or recycling of the materials making up the equipment.

The sanctions currently provided for by law shall apply to users who dispose of products in unauthorised ways.

ASSISTANCE

Silca provides full assistance to purchasers of its key-cutting machines. To ensure complete safety for the operator and the

machine, any job not specified in the manual should be carried out by the manufacturer or in the special service centres recom-

mended by Silca.

Below is a list of Silca specialised Service Centres all over the world.

How to request service

The guarantee attached to our key-cutting machines ensures free repairs or replacements of faulty parts within 24 months of

purchase.

All other service calls must be arranged by the customer with Silca or with a Service Centre.

Silca is always at your disposal for technical information or clarification.