CONCRETE MIXER MOD.: BB 180/250/350/430/ BB350 S / BB500

GB

Operating, maintenance, spare parts manual Rèv. 3 of 11/12/13

Page 17 di 40

THEREFORE, THE COMPANY SILLA CANNOT ACCEPT ANY RESPONSIBILITY, IF THE MACHINE

SHOULD BE USED BY THE OPERATOR FOR DIFFERENT USES THAN THOSE LISTED IN THIS INSTRUCTION

MANUAL OR THOSE NOT COMPLYING WITH THE OPERATING

INSTRUCTIONS.

4.4

Noise

The following table informs on:

- A-weighted sound pressure level at workstations (LpA).

- weighted sound power level emitted by the machinery

(LwA).

The values take into account the uncertainty equal to 3dB and were collected in

the following conditions:

Material being processed :

Sand maximum grain size 3mm, degree of

humidity between 4 and 10%.

Operating conditions :

Machine complete with all parts and ready to ship.

Load of the machine :

Equal to the output capacity indicated in the promotional material.

Observation period :

1 minute for each measurement.

Measuring instrument :

Sound-level meter

Delta Ohm s.r.l. model HD2010UC serial number 08052941513.

Calibration :

Centro SIT n°124 Delta Ohm s.r.l. n° certificate F0527_10 of 07/07/10.

Wind-shield :

Spherical, sponge.

In order to not increase the noise level, strictly follow these rules:

•

Clean and grease the machine elements according to the maintenance schedule;

•

Ensure the machine parts are not obstructed or damaged.

With this noise emission level the use of protective equipment like earmuffs, earplugs, etc. is mandatory.

These noise values are emission levels and not necessarily safe working levels. While there is a correlation between

the emission levels and the exposition levels, it cannot be used in a reliable way to evaluate whether there is or nor the need

for additional precautions. The factors affecting the worker’s real exposition level include the duration of the exposition, the

environmental characteristics, other emission sources like for example the number of adjacent machines and types of

machining. The single exposition levels may also differ from country to country. However, thanks to this information the user

of the machine can better evaluate the dangers and risks.

5.

INSTALLATION

5.1

Transport

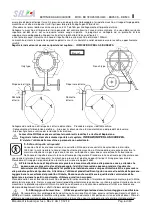

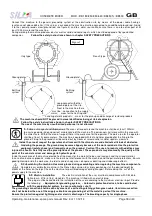

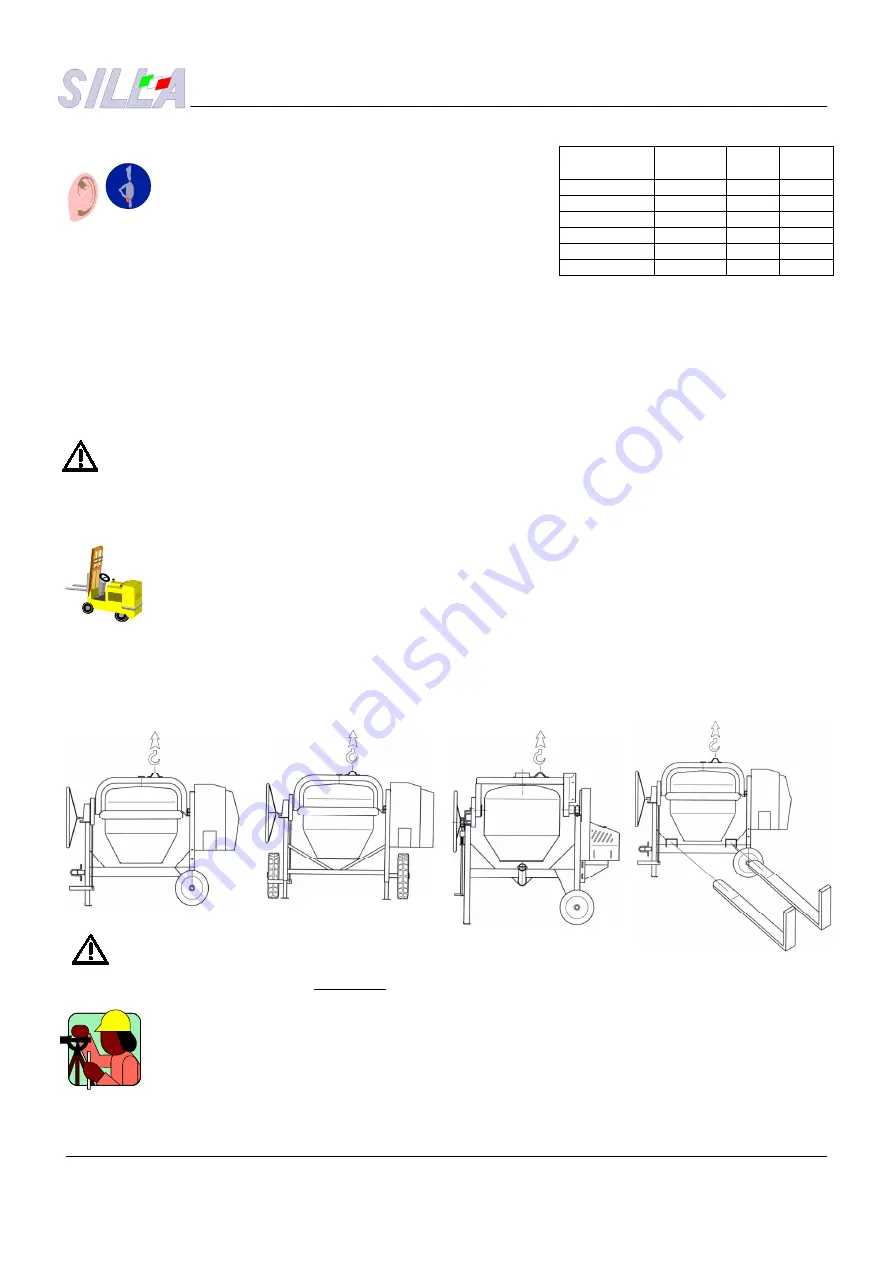

The concrete mixers are delivered assembled, the wheels mounted and the

legs, for the French type version, in the lowest position. Thanks to their solidity and their shape the

machines are easy to handle and to stock without damages. The motor unit and the belt reduction system are

fully assembled on the machine, together with the protections of the belts, the gear and the electric control

board. The weight of the machine is stated on the EC plate; due to its considerable weight, the machine shall not be

manually handled. It shall be hoisted by means of a crane and hooked as shown in the figure. The model BB 500 can also be

hoisted by means of a fork lift, the forks to be inserted into the special housings on the crossbar of the frame.

Lift only 1

machine at a time!

For transportation from site to site, on truck or similar, bind the concrete mixer by means of opposed

belts and nail wedges to the wheels, so that it does not move during the transport.

Italy type

French type

Silenced

BB 500

The machine is delivered with the following accessories: -2 wheels; - 1 drawbar; - 1 series of keys;

Be careful during hoisting and handling the machine to prevent injury to persons and

damages to the machine. The hoisting means shall be dimensioned according to the

weight to be

hoisted

.

We specify the Prohibition of towing the machine on the road. The wheels are used for

handling inside the site (except for French type version and only in France).

Follow the safety instructions shown in chapter SAFETY PRECAUTIONS.

5.2

Placing and grounding.

Install the machine on flat and solid ground. Check the flatness of the ground

before installation by means of a water level (longitudinally and crosswise).

Make sure the ground is correctly dimensioned to support the weight of the machine. It must be self-

extinguishing and not combustible. If necessary, the ground may be provided with holes for screw anchors,

to fix the machine to the ground. The installation place shall be protected against atmospheric agents.

Next to the machine there must be a plug 3 P+T of 16A for the connection to the electric installation.

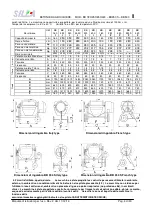

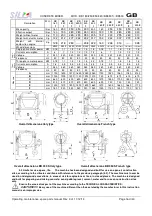

Concrete

mixer

Type of

motor

LpA

(dB)

LwA

(dB)

BB 180

Electric

83,3

97,4

BB 250

Electric

83,3

97,4

BB 350

Electric

83,3

97,4

BB 430

Electric

83,3

97,4

BB 500

Electric

83,3

97,4

BB 350S

Electric

68,1

80,7