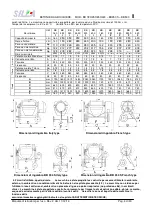

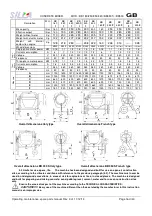

CONCRETE MIXER MOD.: BB 180/250/350/430/ BB350 S / BB500

GB

Operating, maintenance, spare parts manual Rèv. 3 of 11/12/13

Page 18 di 40

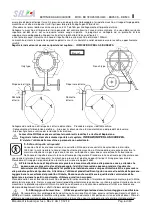

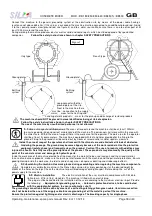

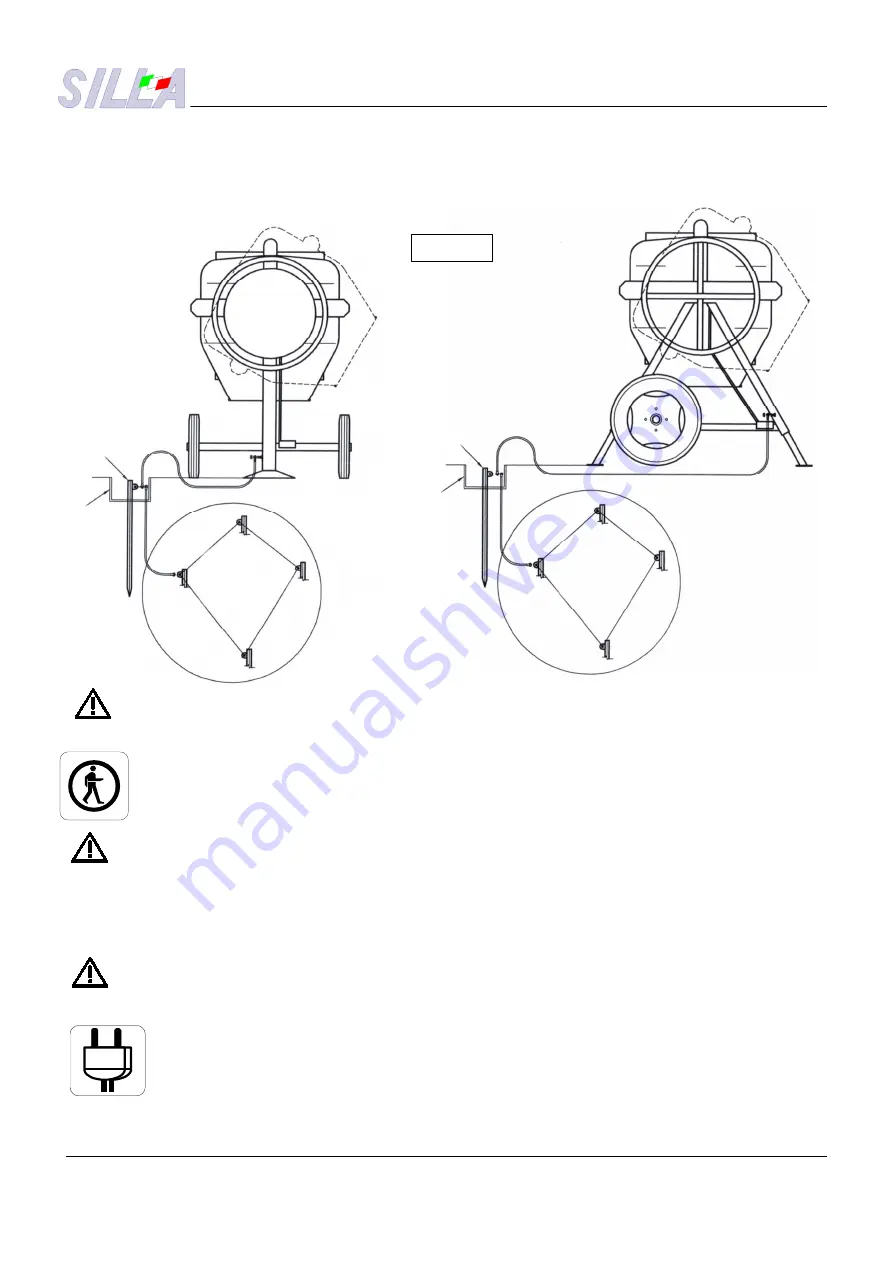

Connect the machine to the general grounding system of the construction site by means of the power cable having a

resistance not above 883 ohm. If this values is exceeded, the machine must be connected to an additional ground rod, linking

it to the special ground screw (ground rod, see figure 2) and to a water source. Make sure there is an area of respect of at

least 1000 mm around the machine.

During working the machine produces dust as well as solid and liquid rejects, which must be disposed of by specialized

companies.

Follow the safety instructions shown in chapter SAFETY PRECAUTIONS

Italy type

French type

Ground plate

Ground plate

Earthing

Earthing

system

system

Loop-connect with other

ground plates of the site.

Next to the machine there

must be: - connection to the supply

mains; - areas for the hoisting and

handling of work products; - areas for the pick-up and discharge of residual products.

The machine should NOT be placed in areas identified as being at risk of explosion.

Follow the safety instructions shown in chapter SAFETY PRECAUTIONS

.

The use of the machine by unauthorized personnel is not allowed.

5.3

Areas of respect and dimensions

The areas of respect around the machine shall be at least 1000mm.

to ensure good working and correct maintenance of the machine. The personnel shall move within this area with

the utmost care. Within the area of respect there is the work area for the operator. The work area for the operator

shall be at least 2 square meters. The machine is equipped with feet and holes provided for the fixing to the

ground. Fixing to the ground shall be carried out by means of screw anchors and/or special screw nuts.

Inside the area of respect the operators shall move with the utmost care and eliminate all kinds of obstacles

hindering the passage. The ground may become slippery because of the work residuals. Use the protective

equipment (safety shoes) and frequently clean the ground. Caution! The use of products with additives may

injuries the health. Carefully read the prescriptions of the product.

These products may also modify the quality of the

paint of the concrete mixer and damage its hydraulic parts.

Inside the work area of the machine provide hoisting means for the material to be used (cement) and the mixed material.

In case of voluminous products, make sure there are no interferences with the machine and the perimeter protections.

Ensure

good lightening inside the work area, in order to avoid shady areas, dangerous dazzling and stroboscopic effects.

5.4

Assembling the machine.

Use work gloves

during assembling and/or replacing the machine components.

Completely assemble the machine, in the French type version, by simply positioning it at the desired height by

means of the holes on the legs. Check the machine for possible damages during transport. Before doing this, cut off the

power supply to the machine.

5.5

Electric installation

The electric installation of the user must be in compliance with CEI 64.8,

Italian law n. 37/8 (in Italy) standards. The machine is fitted with an electric plug.

The plug must be connected to the installation of the user according to the maximum electrical input. Provide

the following:

- Equipotential grounding system, -

Automatic protection devices, to be coordinated

with the equipotential system, to ensure automatic cut-off.

The grounding connection shall be done by means of a self-extinguishing yellow-green cable, its minimum section

shall not be below the one of the supply cable. Ensure grounding of all the metallic parts of the machine.

Ensure the protection against lightning and/or electric discharges. The breaking capacity for single-phase

Figure 2