CONCRETE MIXER MOD.: BB 180/250/350/430/ BB350 S / BB500

GB

Operating, maintenance, spare parts manual Rèv. 3 of 11/12/13

Page 19 di 40

version is 150A, while for three-phase it is equal to 0, because there are no fuses or circuit breakers.

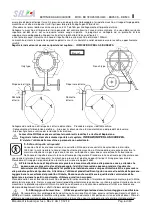

For installations on construction sites, connect the grounding system of the construction site to the additional

external earthing plug, placed on one machine leg: use a copper cable with a minimum section of 35 square

millimetres provided with cable terminal and fix the cable terminal to the clamp on the leg with a screw nut (Fig. 2).

Ensure good light and visibility of the machine installation place, according to the work area, and avoid shady areas,

dangerous dazzling and stroboscopic

effects

.

The Company cannot accept any responsibility in case of wrong electric system

or bad grounding. The motors on the machine are protected by means of a magneto-thermal device.

The motors are provided with special devices to avoid accidental machine starts after electric cut off.

All the elements and electric apparatus are protected according to the place of use, they have a protection grade of minimum

IP 54 (protection from dust and liquids)

.

The control panel is placed so that it is visible by the operator while using the

machine. It is provided with a STOP push-button for stopping the machine

.

Follow the safety instructions shown in chapter SAFETY PRECAUTIONS.

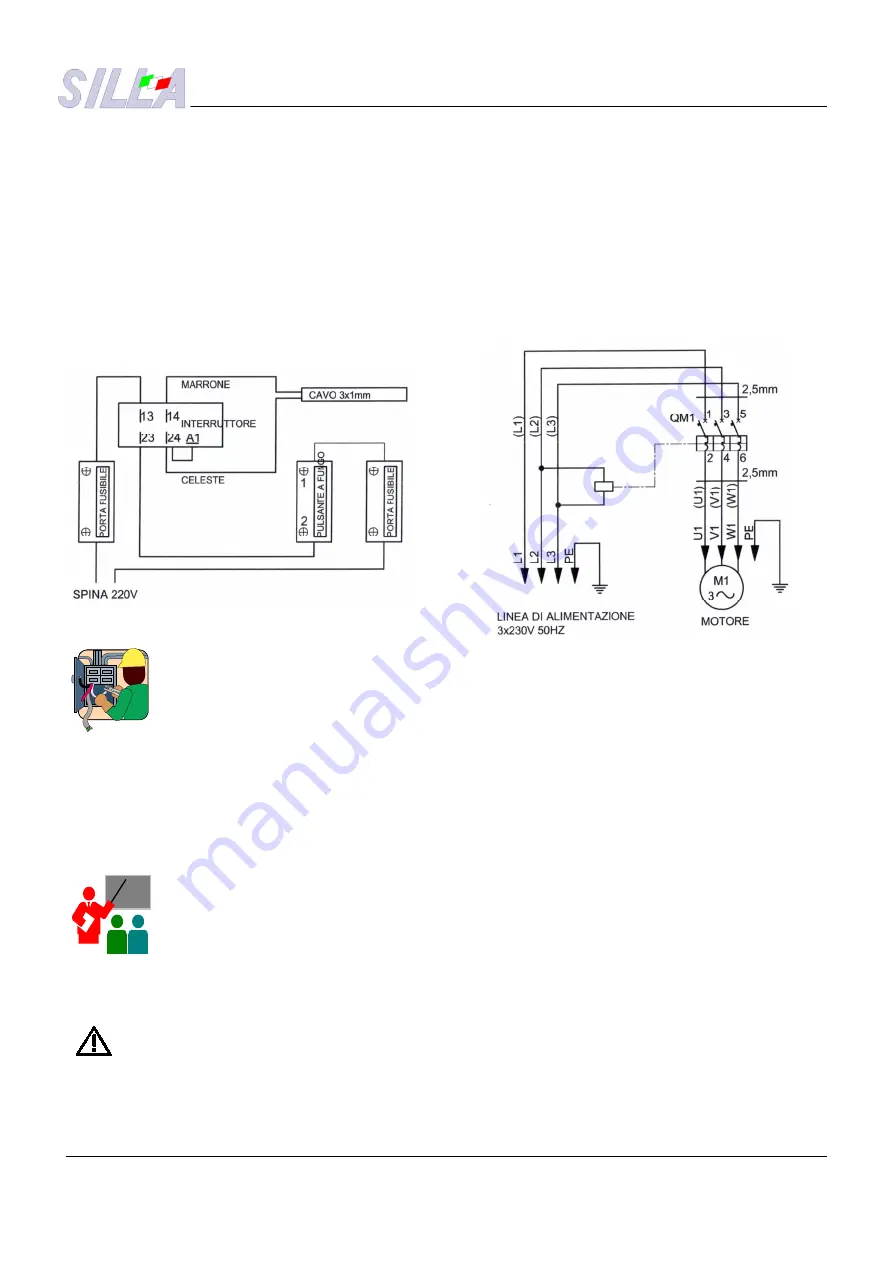

5.6

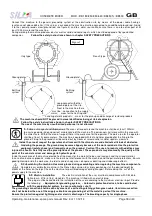

Wiring diagram

Single-phase

Three-phase

5.7

Putting into operation

Before putting the machine into operation, especially the very first time, or

when it is installed on a new work place, carry out the following preliminary checks:

- Check the good positioning and levelling of the machine inside the work area;

- Check the good working of all the transmission and moving parts of the machine; - Check the work surface

for residual materials (packing, etc.), remove foreign bodies from the transmission and moving parts;

- Make sure there are no damaged or locked elements; - Check the tensioning of the feed belts;

- Check the machine elements for complete assembling and clamping;

- Check the area of respect and the work areas; - Check the protection device for good fixing and locking;

- Check the caution/danger signs on the machine for good visibility.

- Ensure good connection of electric supply and grounding;

- Check the compatibility between electric installation and machine (voltage, phases, frequency, power, protection device)

- Check the direction of rotation of the electric motor (for good mixing the drum shall turn in the shown direction);

- Carry out a work cycle without material to check correct adjustments and good machine operation;

- Check the operation of the electric control devices.

5.8

Training.

Before starting use the machine, read this instruction manual and understand

how to use the machine in a safe way.

6.

ADJUSTMENTS

6.1

Adjusting the machine

At first operation on the construction site, the machine does not need any

adjustments. Ensure good assembling and connections: - see paragraph 5.6 Putting into operation.

Never carry out adjustments with the machine running/operating. Follow the safety instructions shown in

chapter SAFETY PRECAUTIONS.

Every single adjustment and/or modification of the safety/work

parameters set on the machine, which has not been authorised by the technical personnel of the company

SILLA or which is not stated in this instruction manual, may influence the quality of the product and injure the

operator’s health. The company SILLA decline any responsibility for liability, performances and safety of the machine

in case of modification/alteration of the machine and of the relevant

OPERATION/SAFETY PARAMETERS.