CONCRETE MIXER MOD.: BB 180/250/350/430/ BB350 S / BB500

GB

Operating, maintenance, spare parts manual Rèv. 3 of 11/12/13

Page 20 di 40

6.2

Adjustment of belts tension.

If the belts slip, disconnect the electrical power supply to the concrete mixer

(remove the plug from the control board), open the door of the cabin,remove the

protection carter, check belt and pulley conditions in order to

carry out the right maintenance.

6.2.1 Tension of the belts.

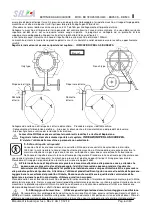

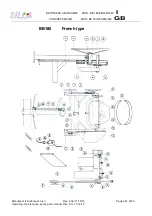

To tighten the belts “1” between motor and snub pulley, loosen screws “2” using a

wrench “17” and slide the support with the motor vertically.

Tighten the screws “2” so that they do not come loose.

If belts have cracks or defects especially on the inner side, replace them.

Otherwise reassemble and tighten the belts as already said.

Reassemble the protections.

Especially with new belts, check once again their tension during the first days of work.

7.

USE

7.1

Controls and location areas

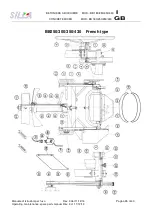

Electric motor only. Electric control panel equipped with the following commands:

1) Green motor START push buttons. 2) Red motor STOP push button.

The control panel has also an electric plug, that must be isolated at the end of work.

The controls on the panel refer to START and STOP of concrete mixer. In the case of

internal combustion engine, to start and stop the machine, see the enclosed instruction

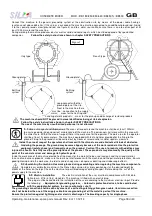

manual for use and maintenance of the motormanufacturer. The tilting of the drum, for

unloading the mixed product, is controlled by a flywheel with reduction system, locked by

a pedal. To tilt the drum the operator shall first press the pedal to unlock the system.

To re-lock the drum in the desired position, remove the foot from the pedal.

For each new mix, place the drum to loading position, otherwise the product will not be

optimal. Correct operator position, also for the version with internal combustion engine,

is the one shown in the figure! It is also the farthest position from the exhaust fumes of the

motor. The use of the concrete mixer is allowed to: adult / professional user or hobbyist /

good health.

During the use, follow the safety instructions

shown in chapter SAFETY PRECAUTIONS.

Before carrying out maintenance or replacing the components

and/or in case of danger, cut off the power supply.

7.2

Working cycle

Before starting the operation cycle, carry out the following checks/operations:

- After the machine has been tooled, the electric and hydraulic system connected and the operator equipped with

the protection equipment (work gloves, safety shoes, ear muffs, dust mask):

- Prepare sufficient aggregate and cement in the work area of the concrete mixer; - Start the concrete mixer positioning the

drum in loading position; - Put about half the quantity of water needed for mixing into the drum;

- Load the drum with the desired quantity of aggregate and cement; - Put the necessary water quantity into the drum;

- Place a crane bucket or a similar container in front of the drum for the mixed concrete;

- After mixing of the materials, overturn the drum to unload the material; - When unloaded, move the drum in loading

position; - After the first mixing, the operator shall repeat the above mentioned instructions and adjust the quantity of

components according to the obtained and the desired product quality; - At the end of work, the operator shall wash the

drum inside and the machine outside, stop the machine, position the drum with the opening downwards so as to avoid water

stagnation inside, disconnect the electric system and carry out maintenance works.

- In presence of gasoline engine or diesel engine, pay attention to the refuelling that should always be performed with a funnel

and cooled machine. Therefore, we recommend to carry out refuelling before the start of any work.

The work shall be done by a single operator. DISCONNECTING

To disconnect the electric system, press the stop push-button and extract the electric plug.

Follow the safety instructions shown in chapter SAFETY PRECAUTIONS.

In case of activation of the emergency devices, the machine will immediately stop. The machine stops in

case of excessive current absorption and/or incorrect supply voltage.

7.3

Safety precautions The dangerous areas of the machine are those near the drum, while rotating

and tilting. Never introduce objects or your hands inside the protections, while the machine is running.

In case of accident, press the emergency stop push-button and assist the operator.

Do not introduce or stock foreign materials inside the machine, on the protections and on the operating elements.

Pay special attention to high temperature elements (electric motor and belts).

Insulating the machine

Before carrying out any operation on the machine (installation, maintenance, replacement

of components, placing, repair, etc.) insulate the machine as follows:

- Stop the machine; - Cut off electric supply;

- Make sure the machine is powerless and the complete lack of residual energies: temperatures.

Only one operator shall be responsible for the execution of all these operations.

ALWAYS USE THE PROTECTIVE EQUIPMENT DURING INSTALLATION, OPERATION AND MAINTENANCE OF THE

MACHINE: WORK GLOVES, SAFETY SHOES, EAR MUFFS, AND MASKS.

On-site

- Ensure sufficient lightening and space for maintenance works and the moving around of the personnel.

Always clean the ground, because dust, water, etc. make the ground become slippery and dangerous.

- Wear tight-fitting clothing. Do not wear any jewellery or clothing that can get caught. – Always use the protective equipment.

On the machine, before starting the work

- Make sure the motor cooling grating is chipless and free of any dirt.