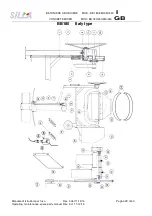

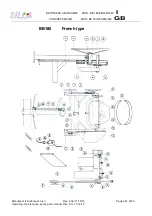

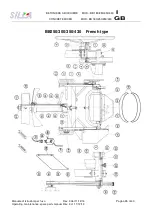

CONCRETE MIXER MOD.: BB 180/250/350/430/ BB350 S / BB500

GB

Operating, maintenance, spare parts manual Rèv. 3 of 11/12/13

Page 21 di 40

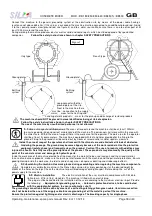

- The concrete mixers are equipped with a magneto-thermal switch with minimum voltage release coil.

- In case the supply voltage does not comply with the specifications or after a short-time cutoff , the minimum voltage coil will

automatically cut off the supply voltage. In such a case you must press the start push-button to restart the machine.

- The motor is equipped with an overload protection; the motor stops in case of overheating. Cool and press the start button.

- The motor is protected from inopportune starts after cutoff

.

ALL MAINTENANCE AND ASSEMBLING OPERATIONS MUST BE DONE, AFTER HAVING DISCONNECTED THE

POWER SUPPLY TO THE MACHINE.

- The machine shall be kept turned off when it is not used. Always carry out a work cycle without material to check good

operation. - Ensure the machine devices and the area in front of the drum are proper and free of obstacles.

- Ensure all the safety devices, control devices and work devices are well positioned.

During operation Use the prescribed protective equipment.

- Never approach the moving and operating elements with your hands, arms or other parts of your body. Remove rubble with

an appropriate device and always with the machine stopped:

never use your hands!

- In case of machine trouble, never

work with the machine running, wait for complete machine stop and finish the work cycle or stop immediately the machine.

- During the operation of the machine, of its elements or of its accessories, it is strictly forbidden to remove any protection,

like cases, barriers or other protection and safety elements. Never modify switches or other safety and/or operating cycle

control devices, because such an intervention could seriously damage the mechanical elements of the machine and injure the

health of the operator. - Pay attention to the operating and the moving parts. - Do not climb or position yourself on or inside

the machine. - In case of machine trouble, stop the machine with the emergency push-button and cut off the electric energy

supply until the trouble has been eliminated.

During maintenance

- Before carrying out any maintenance work, insulate the machine as described at the beginning of this chapter

.

In case of mechanical or electrical troubles, get in touch with the authorised personnel. If the machine is out of service

because of troubles, maintenance or repair works, place a sign.

- Always use the protective equipment during repair and replacement of the machine elements.

- All electric operations must be done by experienced and authorised personnel.

- Regular maintenance of the mechanical and electrical elements ensures a long machine life, best performances and a high

safety factor. Periodically check proper grounding, according to the standards in force. - Before starting the machine, check

the inside and outside of the machine for possible tools or foreign matters and remove them.

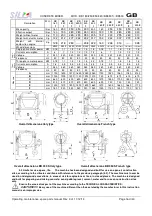

Safety signs:

Caution electrocution hazard

Ground connection point

(on components of the electric system)

Caution moving parts

Direction of motor rotation

(next to the drum)

Wear ear protection

Anchorage / hoisting point

(ear muffs or plugs)

(On the machine there are instructions about residual hazards, follow these instructions.)

8.

MAINTENANCE

The machine does not require any particular maintenance work.

The technical solutions and the components installed on the machine reduce the maintenance works at the

minimum. However, we recommend to carry out a series of operations, which aim at ensuring safety,

liability and efficiency of the machine for a long period of time.

For electric concrete mixer the following is required before any maintenance work:

-

stop the machine by means of the STOP push-button; - remove the power supply plug of the machine;

make sure that no one restores power supply to the machine.

During maintenance work, place a special sign on the electric panel and on the machine to highlight this status.

Never make any modifications to the machine. Use the protective equipment during maintenance work: work gloves,

safety shoes, masks, and goggles. For a right use and maintenance of the internal combustion engine, please follow

the directions of the attached manual, by the engine manufacturer. However, before any maintenance work:

- stop the machine by means of the stopping device installed on the motor; - make sure that no one starts the engine

during maintenance, place a special sign on the machine to highlight this status.

8.1

Preventive (routine) maintenance

To be carried out every day at the end of the work:

- Clean the work areas, the drum and the operating mechanisms.

- Blow away the dust on the machine and on the motor protection grating with compressed air

- Remove any deposits from the work and support surfaces. - Check the supply cable and make sure that it is

undamaged. - Periodically check the belts and replace them, if necessary. - Clean the ground and remove any rubble.

Always remember that scrap is special waste and must be disposed of according to the laws in force.

To be carried out weekly:

- Check locking of the mechanical components. - Check protections and

ensure their good operation, replace if necessary. - Lubricate at least 1 time a week the pinion and gear of the