Copyright Donald W Thomas, K5ZRQ

5

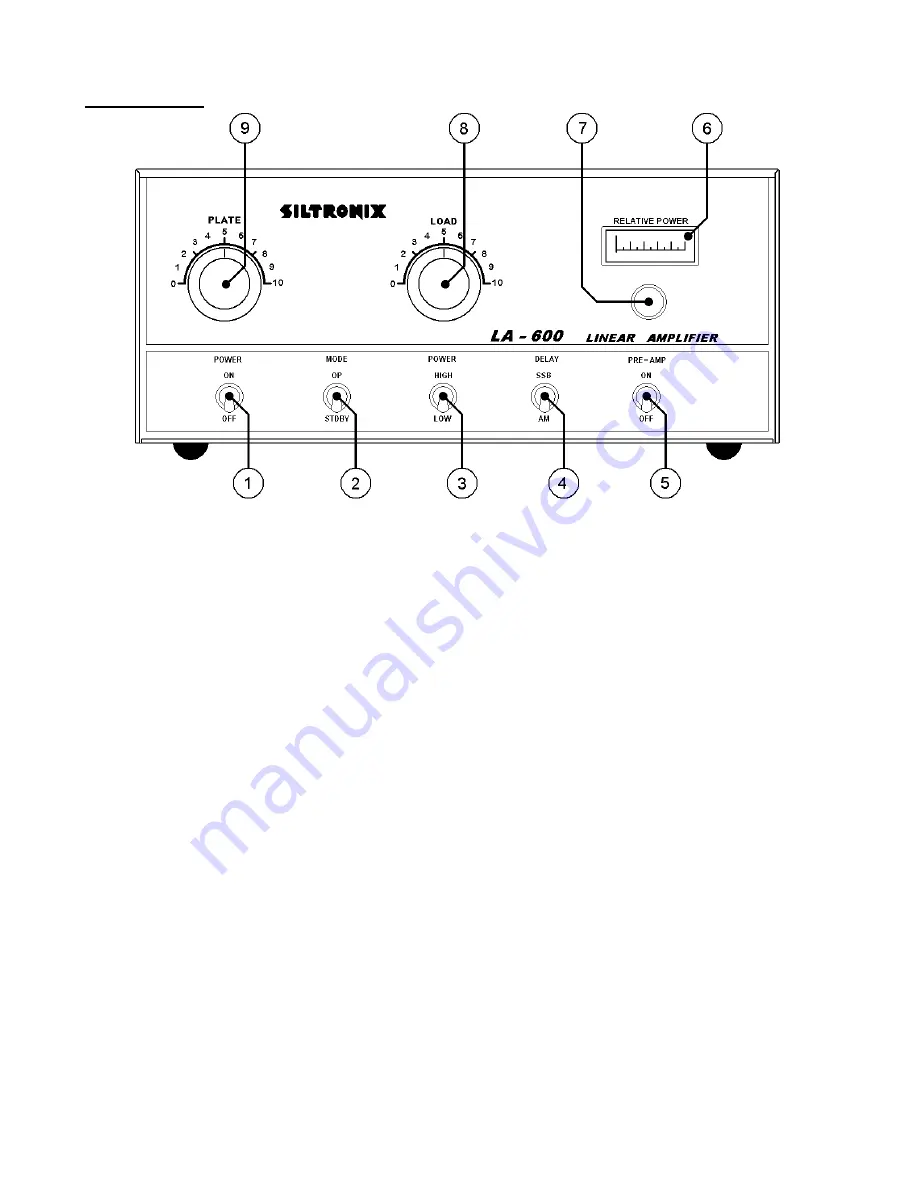

3.0 CONTROLS:

3.1 Front Panel

Figure 2-1 Front Controls

1.

POWER:

Switches AC power “On” and “Off”

2.

MODE:

STDBY Position: Exciter operated directly into the antenna on transmit.

OP Position: Transmitting amplifier will be switched in when the exciter is

in AM and keyed or when the exciter is keyed in SSB with

modulation applied.

3.

POWER:

LOW Position: Provides 300 Watts AM RF Output for the nominal 3 watts input.

HIGH Position: Provides 500 Watts AM RF Output for the nominal 3 watts input.

4.

DELAY:

SSB Position: Allows the relay to remain in “Transmit” mode during short

pauses while transmitting.

AM Position: Continuously keeps the LA-600 in the transmit mode so long

as the exciter is in transmit.

5.

PRE-AMP:

OFF Position: Exciter receives signal directly from antenna.

ON Position: Exciter receives signal from PRE-AMP which provides

approximately 6 db gain. The PRE-AMP switch operates

independently of the mode switch. The PRE-AMP is

disabled during transmit.

6.

RELATIVE POWER METER:

Reads relative output RF power.

7.

PILOT LIGHT:

Red lamp indicator shows when amplifier is powered on.

8.

LOAD:

Used to properly match the amplifier plate circuit to the antenna.

9.

PLATE:

Used to tune the PA output to resonance.