japa

315+

User manual

Translation

21

315+ 2.0 - 2020

5.2 First maintenance

In order to ensure a long service life for your machine, we recommend replacing the hydraulic oil filter

in conjunction with the first 50 hr maintenance. This ensures that impurities are removed from the

system.

5.3 Daily maintenance (10 hr)

The daily maintenance is intended to be performed between instances of use. The maintenance

consists of checking the fluid levels and the cutting and splitting knives, and testing the operation of the

machine and safety equipment. Test the operation of the machine and its safety equipment in

accordance with Section 3. Do not use the machine if the safety mechanism does not function (3.3).

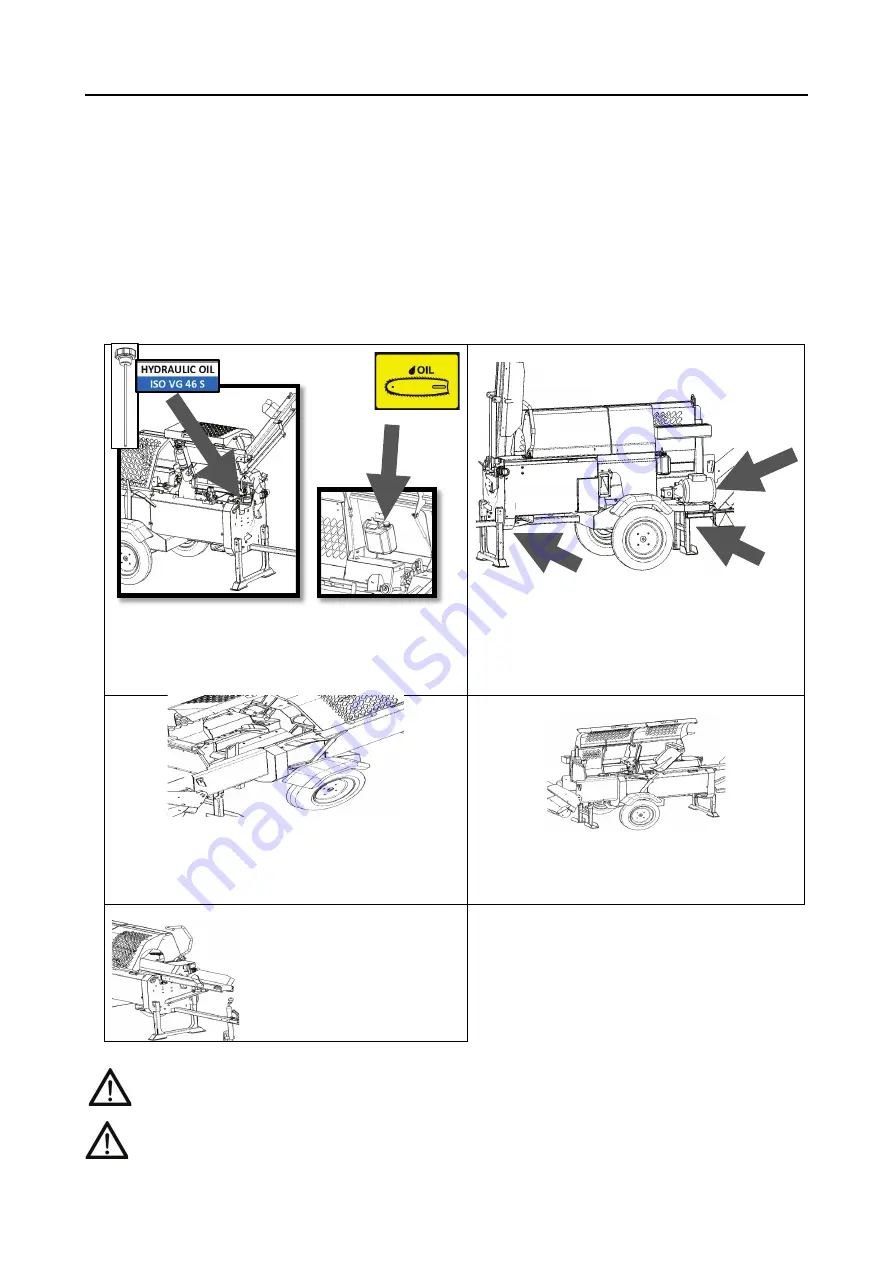

A. Check the fluid levels.

Volume of the saw lubrication tank 3 l, hydraulic oil

30 l.

NOTE! Hydraulic oil level is indicated by the 10 cm

dipstick.

B. Cleaning.

Clear sawdust and debris from the front of the

ventilation openings as well as beneath the

sawdust removal openings. Keep the battery

(accessory) clean and dry, and ensure that the

terminals and cable shoes are free of deposits.

C. Splitting knife.

Open the splitting guard and lift the knife to the

upper position in order to facilitate inspection.

Sharpen the knife if necessary (5.3.2).

D. Cutting saw.

Open the working area guards and sharpen or

tension the chain as necessary (5.3.1).

E. In-feed conveyor

Ensure that the in-feed

conveyor’s belt is properly

aligned and tight. Adjust the

belt if necessary (5.3.3).

ALWAYS DEACTIVATE THE MACHINE AND DISCONNECT THE POWER SOURCE WHEN CARRYING

OUT MAINTENANCE!

THE TRH MODEL DOES NOT FEATURE ITS OWN HYDRAULICS OR HYDRAULIC TANK!