6

Pump Lubrication:

Pump should be periodically oiled by

applying 10 to 12 drops of light oil

down the pump rod through the

opening in the pump cap as shown.

Pump Disassembly & Reassembly:

NOTE: Remove pump from tank prior to disassembly.

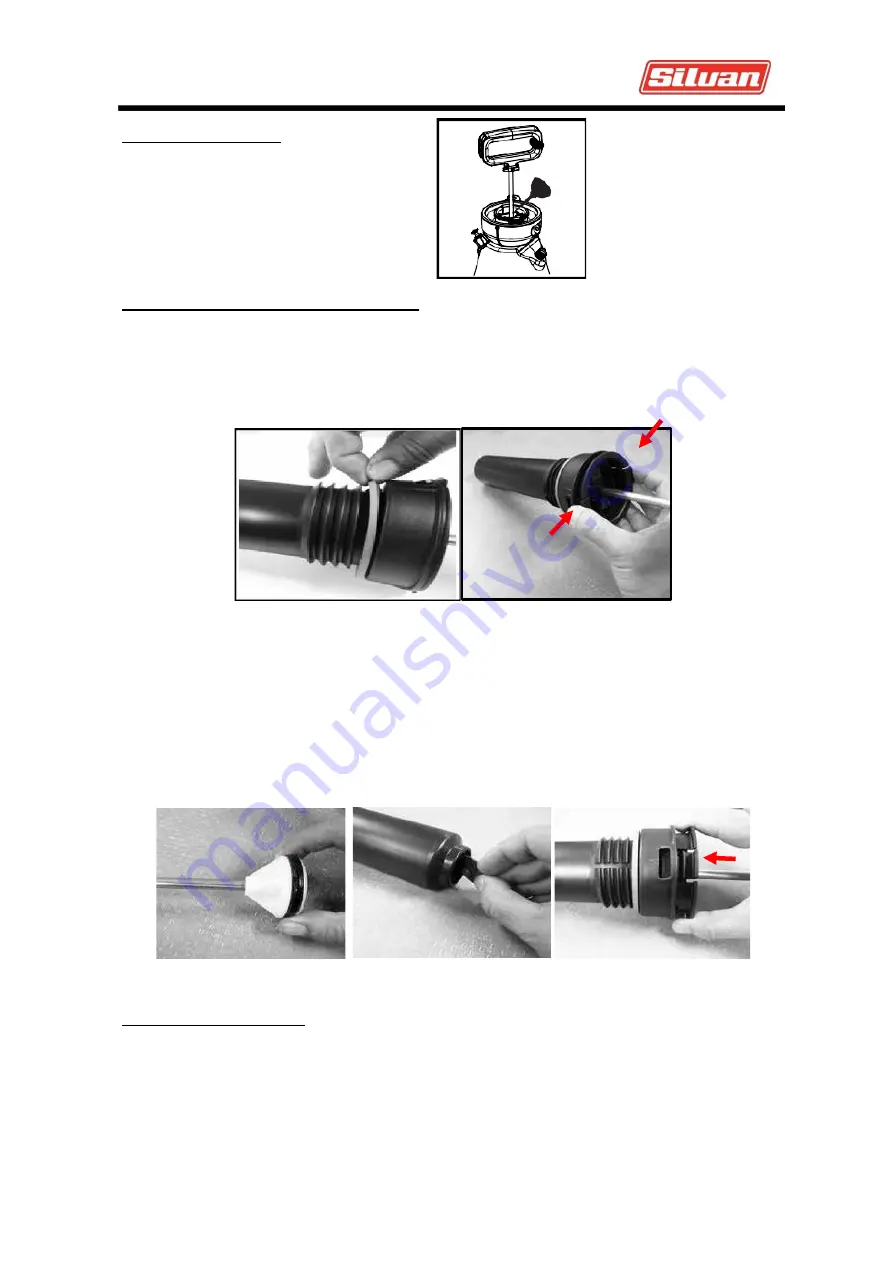

1. Inspect gasket. If worn or damaged, remove and replace. (

See Figure 1

)

2. To remove pump cap from pump barrel, squeeze the tabs on the cap and pull away from

barrel. (

See Figure 2

)

Figure 1 Figure 2

3. Inspect O-ring. If worn or damaged, remove and replace. Lubricate O-ring with petroleum

jelly. (

See Figure 3

)

4. Inspect check valve in bottom of barrel. If worn or damaged, remove and replace by

pressing into hole in bottom of barrel. (

See Figure 4

)

5. Insert the pump handle assembly into the barrel. Align the tabs of the pump cap with the

rectangle cut-outs on the barrel. Push cap into place until the cap snaps securely into

position. (

See Figure 5

)

Figure 3 Figure 4 Figure 5

Nozzle Maintenance:

1. If nozzle clogs, remove and disassemble the nozzle assembly.

2. Clean the openings of any obstructions and reassemble.

Maintenance