SETUP AND TESTING

It is always recommended that you first test all spray equipment thoroughly with clean water. Silvan

Rakpack’s are supplied with a blue adjustable nozzle containing a large orifice, which when twisting

the tip can allow for a greater flow of liquid. It is recommended that the adjustable nozzle is used

first with the spray gun and can be changed later if you require.

Release the elastic straps that secure the spray hose to the tank and remove the lance and hose

from the transport recesses on the tank.

1.

Be sure to wear safety equipment as recommended by the chemical manufacturer before

adding chemical to the sprayer

2.

Check the suction line foot filter is clean and undamaged (see Maintenance section).

3.

Fill the tank with clean water.

4.

With the 12-volt supply connected and the 6-meter spray hose and spray lance connected. Fit

the blue adjustable nozzle or any large orifice nozzle you may wish to use.

5.

Check all hoses, hose clamps and connections for leaks or damage.

6.

Switch the pump ON.

7.

Depress the spray lance trigger. The pump is self-priming and will start spraying within 30

seconds.

8.

Check the hose connections for leaks, if any are found stop the pump and rectify the problem

before continuing.

9.

By twisting the tip of the nozzle to the coarsest droplet size, the restriction to flow is minimized

and pump pulsation will not occur.

10.

Slowly twist the tip of the nozzle from a course droplet size to a fine droplet to your preference.

If the pump begins to pulsate/cycle you may require a different nozzle that is rated to allow for

higher flow rates at your selected droplet size at approximately.

11.

Once the nozzle is set and the pump operates free of pulsation/cycling, the spot sprayer is ready

to be utilized for spot spraying of chemical.

•

Chemical solution may now be added to the tank.

•

Follow the mixing instructions and safety precautions provided by the chemical manufacturer.

Before adding concentrated chemicals, partially fill the tank with water then add the chemical

and complete filling with water.

•

Wear all the safety equipment recommended by the chemical manufacturer before adding

chemical to the sprayer and whilst conducting spraying operations.

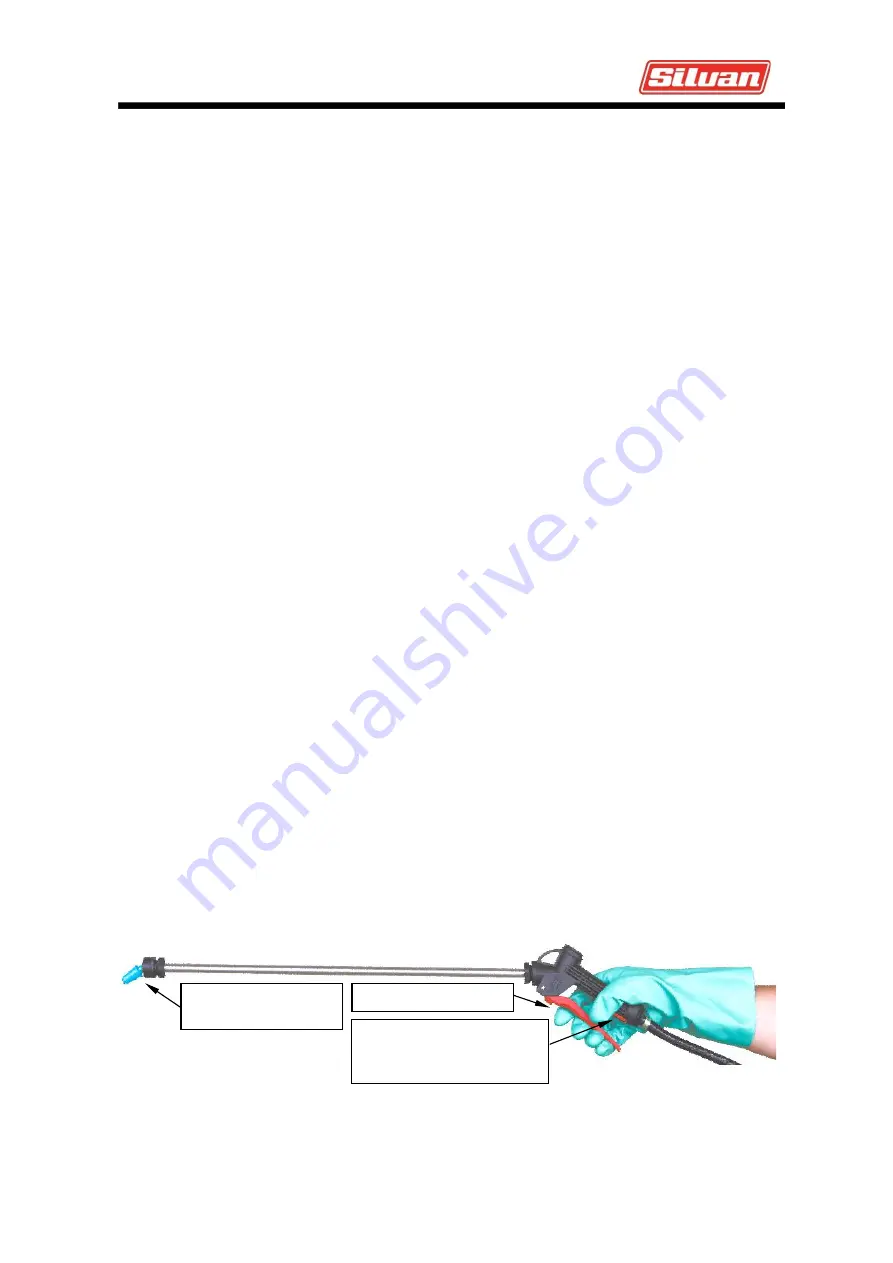

For safety, the spray gun has a catch that can be used to lock the lever closed to prevent accidental

spraying. The catch can also be used to lock the lever open for continuous spraying. This should only

be done when safe to operate in this manner and where there is no likelihood of inadvertently

spraying any person or property that may suffer damage.

Operation

Turn nozzle to adjust

spray pattern

Depress lever to spray

Move red catch back to lock

lever in ‘on’ or ‘off”

position. Only if safe to do

so.