13

Thermistor Field Testing

Use the guide below to test if a thermistor (temperature probe) is functioning properly. See the replacement parts list for

part number information. Table 2 is valid for all thermistors listed on table 1.

•

Establish Thermistor Temperature

▪

Check the display’s temperature reading.

▪

If a thermometer is available, use it to confirm the display’s

temperature reading by taking the temperature at the

thermistor.

▪

If the previously stated tasks are unavailable, then use any

reasonable means to estimate the thermistors temperature.

See form M164 for ice bath method. (ice water is 32

°

F)

•

Multimeter Set-up

▪

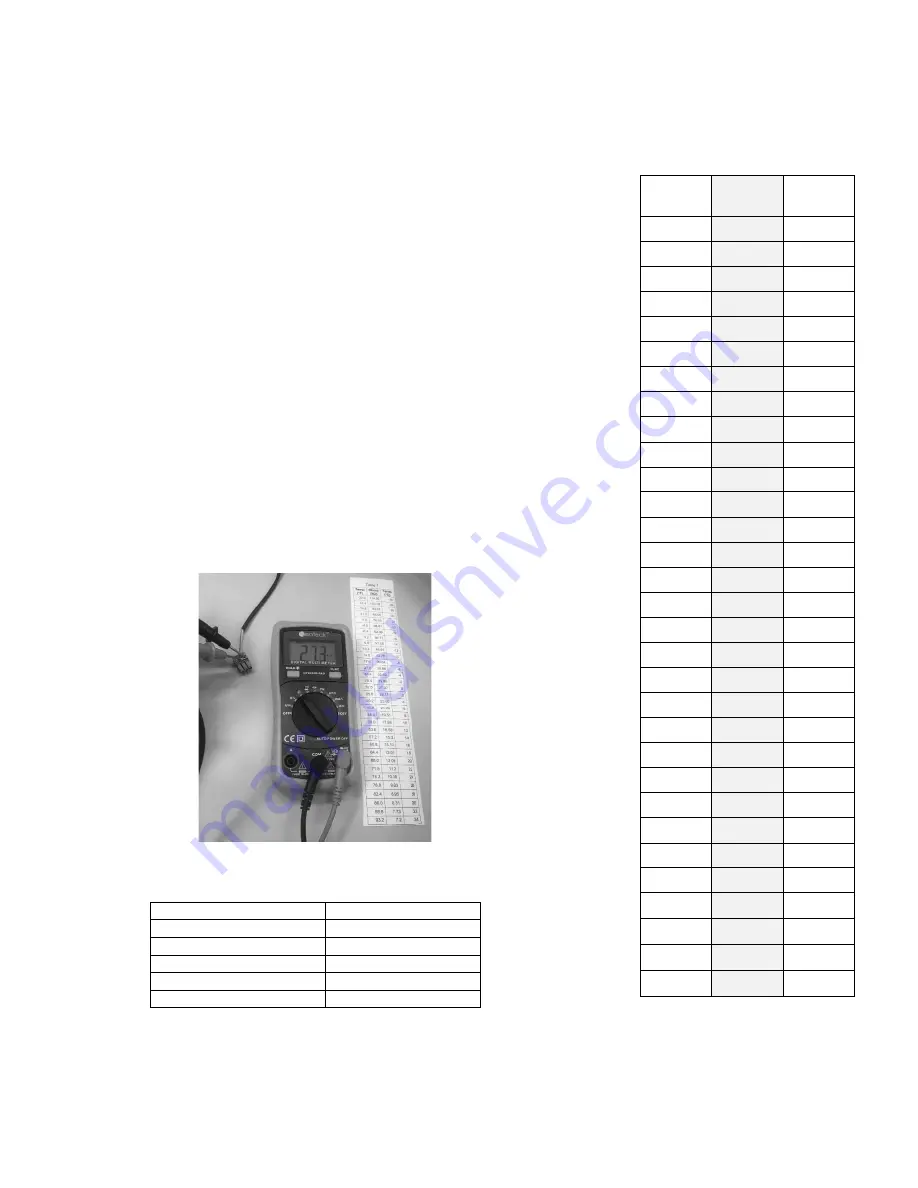

Use a multimeter and set it to the resistance (Ω) setting. See

Figure 1.

▪

Disconnect the thermistor from the controller, then connect the

multimeter to the thermistor. See Figure 1.

▪

Check and compare the multimeter’s reading to Table 1.

•

Analyze Results

▪

If the resistance and temperature are similar, then the

thermistor is working properly and does not need to be

replaced.

▪

If the resistance and temperature are not similar or the

resistance’s value is not on Table 1, then the thermistor is not

working properly and needs to be replaced.

▪

If the resistance reads over-limit, then the thermistor is not

working properly and needs to be replaced.

Figure 1

Table 1

Thermistor Description

Part Number

60” black

46128

120” black

46141

60” green

46127

120” green

46140

96” black

38822

Table 2

Temp

(

°

F)

Ohms

(kΩ)

Temp

(

°

C)

-4.0

67.8

-20

-0.4

61.5

-18

3.2

56.0

-16

6.8

51.0

-14

10.4

46.5

-12

14.0

42.5

-10

17.6

38.8

-8

21.2

35.4

-6

24.8

32.4

-4

28.4

29.7

-2

32.0

27.3

0

35.6

25.0

2

39.2

23.0

4

42.8

21.2

6

46.4

19.5

8

50.0

18.0

10

53.6

16.6

12

57.2

15.3

14

60.8

14.1

16

64.4

13.0

18

68.0

12.1

20

71.6

11.2

22

75.2

10.4

24

78.8

9.6

26

82.4

8.9

28

86.0

8.3

30

89.6

7.7

32

93.2

7.2

34

96.8

6.7

36

100.4

6.3

38

104

5.8

40

P/N 45810 - Rev C