5

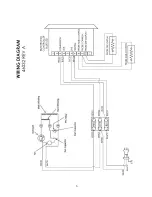

ITEM NO

PART DESCRIPTION

PART NO

1

LOWER COVER INSULATED

2

UPPER COVER INSULATED

3

END PANEL LOUVERED

4

POWER CORD 115V

5

KIT 5" CASTER

6

GROMMET COMPRESSOR MOUNT

20481

7

WASHER COMPRESSOR MOUNT

8

CLIP HAIRPIN COMPRESSOR MOUNT

9

KIT COMPRESSOR 115V/60HZ R290 (W/DRIER AND ELECTRICALS)

10

KIT COMPRESSOR ELECTRICAL 115V (RELAY/OL/CAPACITORS)

11

FAN MOTOR CONDENSER 115V-230V

12

DRIER

13

CONDENSER COIL

14

TEMPERATURE CONTROL - ELECTRONIC 115V

15

TEMPERATURE/DISPLAY PROBES

16

STOPPER DRAIN

17

CORD WRAP

18

GUARD BOTTOM LH

19

GUARD BOTTOM RH

20

BUMPER CORNER

21

CAPILLARY TUBE (NOT SHOWN)

FORM 46377

REPLACEMENT PARTS LIST – SKFMW50-ESUS1

WHEN ORDERING REPLACEMENT PARTS, PLEASE PROVIDE MODEL AND SERIAL NUMBERS.