13

Thermistor Field Testing

Use the guide below to test if a thermistor (temperature probe) is functioning properly. See the replacement parts list for

part number information. Table 2 is valid for all thermistors listed on table 1.

•

Establish Thermistor Temperature

Check the display’s temperature reading.

If a thermometer is available, use it to confirm the display’s

temperature reading by taking the temperature at the

thermistor.

If the previously stated tasks are unavailable, then use any

reasonable means to estimate the thermistors temperature.

See form M164 for ice bath method. (ice water is 32

°

F)

•

Multimeter Set-up

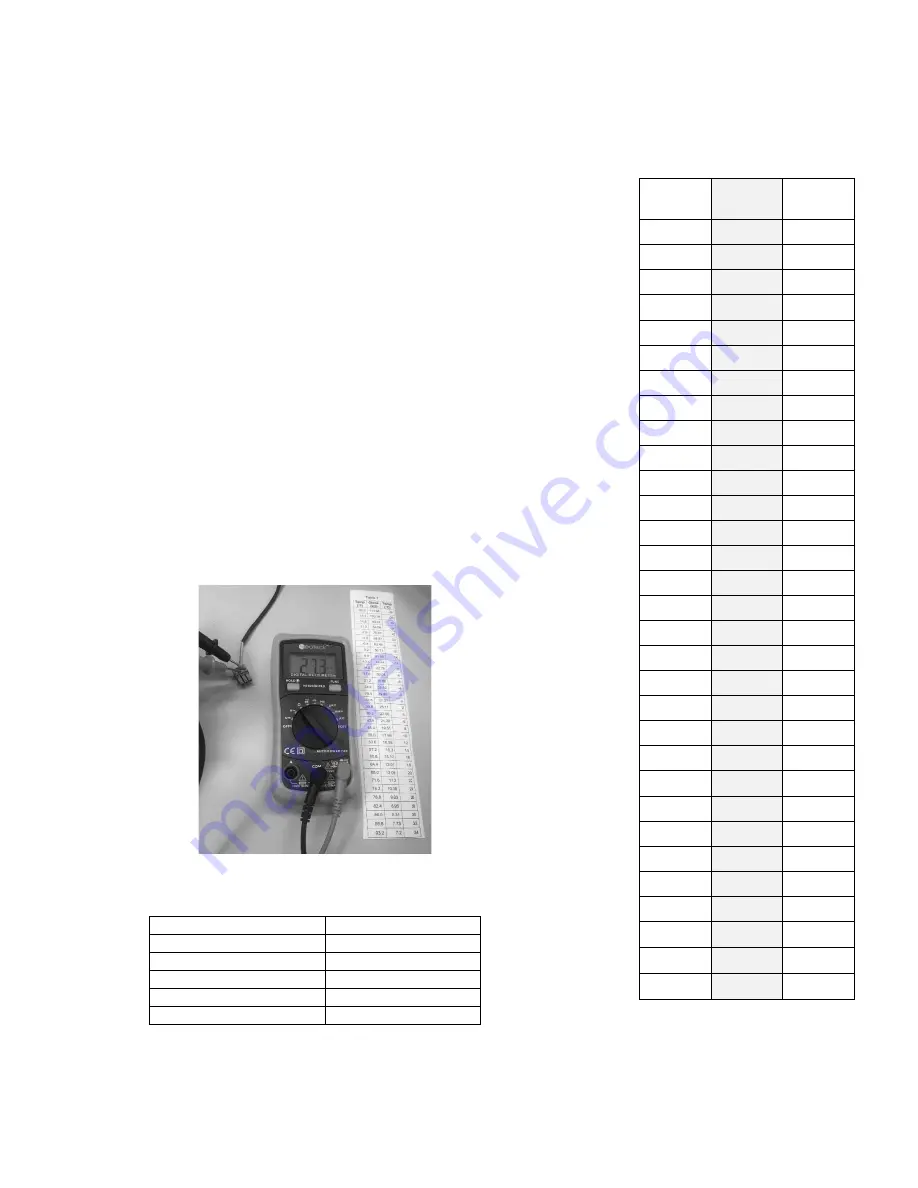

Use a multimeter and set it to the resistance (Ω) setting. See

Figure 1.

Disconnect the thermistor from the controller, then connect the

multimeter to the thermistor. See Figure 1.

Check and compare the multimeter’s reading to Table 1.

•

Analyze Results

If the resistance and temperature are similar, then the

thermistor is working properly and does not need to be

replaced.

If the resistance and temperature are not similar or the

resistance’s value is not on Table 1, then the thermistor is not

working properly and needs to be replaced.

If the resistance reads over-limit, then the thermistor is not

working properly and needs to be replaced.

Figure 1

Table 1

Thermistor Description

Part Number

60” black

46128

120” black

46141

60” green

46127

120” green

46140

96” black

38822

Table 2

Temp

(

°

F)

Ohms

(kΩ)

Temp

(

°

C)

-4.0

67.8

-20

-0.4

61.5

-18

3.2

56.0

-16

6.8

51.0

-14

10.4

46.5

-12

14.0

42.5

-10

17.6

38.8

-8

21.2

35.4

-6

24.8

32.4

-4

28.4

29.7

-2

32.0

27.3

0

35.6

25.0

2

39.2

23.0

4

42.8

21.2

6

46.4

19.5

8

50.0

18.0

10

53.6

16.6

12

57.2

15.3

14

60.8

14.1

16

64.4

13.0

18

68.0

12.1

20

71.6

11.2

22

75.2

10.4

24

78.8

9.6

26

82.4

8.9

28

86.0

8.3

30

89.6

7.7

32

93.2

7.2

34

96.8

6.7

36

100.4

6.3

38

104

5.8

40

P/N 45810 - Rev C