8

GB

1. Slowly turn the Knurled Pattern Adjustment Screw (7) anticlockwise to

adjust the spray pattern. Turn until the desired spray pattern is reached

Note

: Turning the pattern adjustment screw anticlockwise increases the

spread, turning it clockwise leads to a narrower, more circular spray pattern.

2. Turn the Air Nozzle (5) to adjust the orientation of the spray pattern

(see Fig. A)

3. Once you reached the desired spray pattern, release the Trigger (11)

and tighten the Air Nozzle Locking Ring (6) by hand, to lock the air

nozzle in place

Note

: In most operations the wings on the air nozzle should be horizontal to

provide a vertical spray pattern which gives maximum coverage as the gun

is moved backwards and forwards parallel to the surface being painted.

Operation

Trigger operation

• The trigger has a 2-stage mechanism:

• Press to the first stage, the air will flow through the gun

• Press further and the paint is released

Note

: Adjusting the Knurled Needle Adjustment Screw (9) will determine

how far the trigger can be depressed

Spray technique

• To achieve a smooth, even coat, the material must be prepared and

thinned in accordance to the manufacturer’s guidelines

• The gun must be clean and correctly loaded, the spray pattern adjusted

and the compressor set at the correct pressure

• Always carry out a test spray and follow the procedures described in

‘Adjusting the spray gun’, to establish the best settings

• Keep the distance of the spray gun approximately 200-250mm away

from the workpiece

• Spray workpiece edges first. Overlap approximately 50% of each applied

spray beam

• Spray in continuous, even motion. Keep your hand as steady as possible

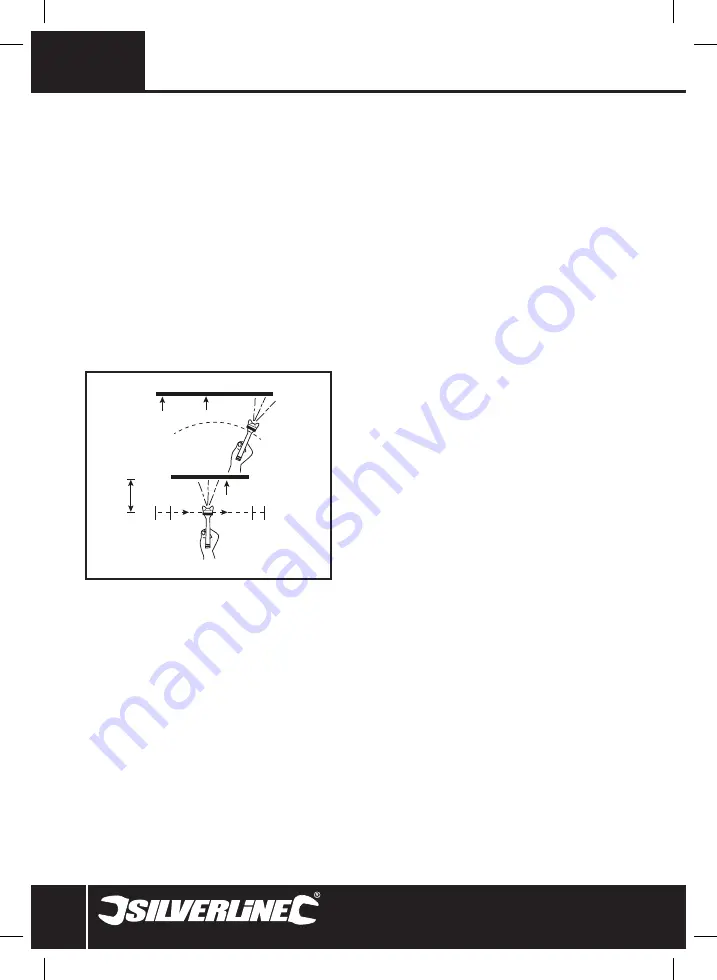

and move the spray in a straight pass across the workpiece (see Fig. B)

• Do not operate in an arc motion. Arcing will lead to an uneven finish

(see Fig. B)

• Avoid intensive waving, as it will cause the air jacket to become unstable,

allowing clouds of atomized spray material to escape

• Before spraying it is good practice to visualise the entire spraying

process. Start with the least visible areas and work towards the parts

that will be seen. This will create an even finish, allow you to identify

problematic areas of the workpiece, and let you work around spots that

may already have been covered

• After use, immediately disconnect the spray gun from the air supply

WARNING

: Be aware that air tools may hold residual pressure after use.

Always bleed air pressure from the tool after shutting off air supply.

Maintenance

WARNING

: Always disconnect from the air supply and depressurise before

disassembly or carrying out any maintenance.

WARNING

: Always wear suitable protective equipment including eye and

respiratory protection as well as gloves when carrying out cleaning or

maintenance procedures.

WARNING

: The majority of solvents used for painting applications are

toxic and highly flammable. Comply with local laws and regulations with

regards to handling, storage and disposal of solvents and other harmful and

potentially dangerous substances.

Note

: Your spray gun is a fine precision instrument and must be treated and

maintained accordingly, in order to achieve consistent, professional-looking,

uniform results.

• The most common problems with spray guns are caused by paint being

allowed to dry inside the tip, nozzle or internal air/fluid passages

• Clean the entire spray gun thoroughly after each project, and also when

changing the type of material being sprayed

• Always use the same solvent for cleaning that was used to thin the paint

General cleaning after every use

1. Remove the paint container, empty remaining material into a suitable

sealed container, and clean thoroughly with the appropriate solvent

and clean cloths

2. Clean the nozzle assembly of the gun, lid and gasket of the paint

container

3. Pour a small amount of solvent into the clean paint container and re-fit

it to the gun

4. Connect the gun to the air supply

5. Direct the gun towards an empty container and spray the solvent

through the gun into the container, until the spray is clear of any paint

6. Turn off the air supply and disconnect the gun

7. Release the paint container, empty remaining solvent into the disposal

container, and let all components dry thoroughly

8. Re-fit paint container for storage

WARNING

: In order to prevent solvents and other harmful substances from

entering the atmosphere, open solvent cleaning is not permitted in some

territories, and special cleaning procedures apply (e.g. cleaning inside

special closed bags and containers, etc.). Familiarise yourself with local

regulations, and apply the recommended procedures.

Special cleaning procedures for air and fluid nozzles and

needles

WARNING

: All nozzles and needles are precision made. They must be

handled with the utmost care. Damage and alterations will cause decreased

performance or faulty spray.

WARNING

: Needles have a sharp point. Handle with care to avoid puncture

wounds and other injuries.

1. Referring to the ‘Assembly Diagram’, carefully disassemble the spray

gun, remove the nozzle assembly and fluid needle

2. To clean, soak nozzles and needle in a suitable solvent that dissolves

any dried material and clean with a suitable soft brush

Note

: Never soak the entire spray gun in solvent, as this will damage the

packings and remove lubrication.

3. Carefully blow all components clean with filtered compressed air

WARNING

: Do not probe any of the holes in the nozzles with metal

instruments. If mechanical cleaning becomes necessary, use only

implements from materials softer than brass, such as specialised nozzle

cleaning aids.

Coating will be

light at this point

Start

stroke

Pull

trigger

Release

trigger

End of

Stroke

Coating will be

heavy at this point

Correct

Wrong

Coating should be even

and wet when spraying

200-250mm

Fig. B

196536_Z1MANPRO1.indd 8

04/07/2013 17:48

Summary of Contents for 196536

Page 2: ...2 1 2 3 4 5 6 7 8 9 10 11 12 13 196536_Z1MANPRO1 indd 2 04 07 2013 17 48...

Page 52: ...52 NL NL Assembly Diagram 196536_Z1MANPRO1 indd 52 04 07 2013 17 49...

Page 54: ...54 NL NL Notes 196536_Z1MANPRO1 indd 54 04 07 2013 17 49...

Page 55: ...www silverlinetools com 55 Notes 196536 196536_Z1MANPRO1 indd 55 04 07 2013 17 49...