6

GB

Operation

*See also paint manufacturer’s instructions

Preparing paint container

1. Unscrew Paint Container (12) from Spray Gun (2)

2. Align the feed tube in the container as follows:-

For horizontal spraying (e.g. walls): turn feed tube so that it faces towards the

surface to be sprayed- To spray surfaces overhead (e.g. ceilings): turn feed

tube so that it faces away from the surface to be sprayed

3. Fill Paint Container with paint to be sprayed. Place Paint Container on level

surface. Stir the prepared paint so that it is thoroughly mixed together.

Carefully fill the Paint Container to a maximum capacity of 700ml

4. Screw Paint Container tightly back onto Spray Gun

Adjusting the spray pattern

Three settings are available to meet different spraying requirements:

• Vertical flat jet (A) for spraying onto vertical surfaces (e.g. onto walls)

• Horizontal flat jet (B) for spraying onto horizontal surfaces (e.g. onto ceilings)

• Circular jet (C) for spraying into corners, edges and hard-to-reach areas

Fig A

- Spray Pattern Adjusters (15) horizontal and raised

Fig B

- Spray Pattern Adjusters vertical and raised

Fig C

- Spray Pattern Adjusters flat with Air Cap (14). May be in horizontal or

vertical position

WARNING:

Never pull the Trigger (13) whilst adjusting the spray pattern

1. Unscrew the Nozzle Assembly Cap (1) slightly

2. Rotate the Air Cap (14) to the required position

3. Set the Spray Pattern Adjusters on the Air Cap to required setting (see

Settings above)

4. Tighten the Nozzle Assembly Cap

IMPORTANT:

The Spray Pattern Adjusters adjust between 0 - 45° only.

Preparing to spray

• Insert plug into mains outlet

• Place the Spray Gun (2) in the gun holder on the Turbine Unit (9)

• Lift the machine and place the strap over your shoulder if carrying. Adjust for

comfort

• Remove Spray Gun from gun holder and check you can comfortably reach all

areas for spraying

Switch the machine on

• Set the On/Off Switch (6) to the ON position to switch on power

• To switch off power after use, set the On/Off Switch to the OFF position and

remove the mains plug from the mains socket

Adjusting the flow rate

• The flow rate of the paint can be adjusted by using the Air Volume Adjuster (3) to

increase or decrease the amount of paint sprayed

• Turn Air Volume Adjuster anti-clockwise to reduce flow rate

• Turn Air Volume Adjuster clockwise to increase flow rate

NOTE:

For most wall paints, an average flow setting provides best results

Spraying technique

• Test the Spray Gun (2) on cardboard or a similar surface to find the correct

flow rate

• Squeeze the Trigger (13) to start spraying. Release the Trigger to stop spraying

• Start at the edge of the area to be sprayed

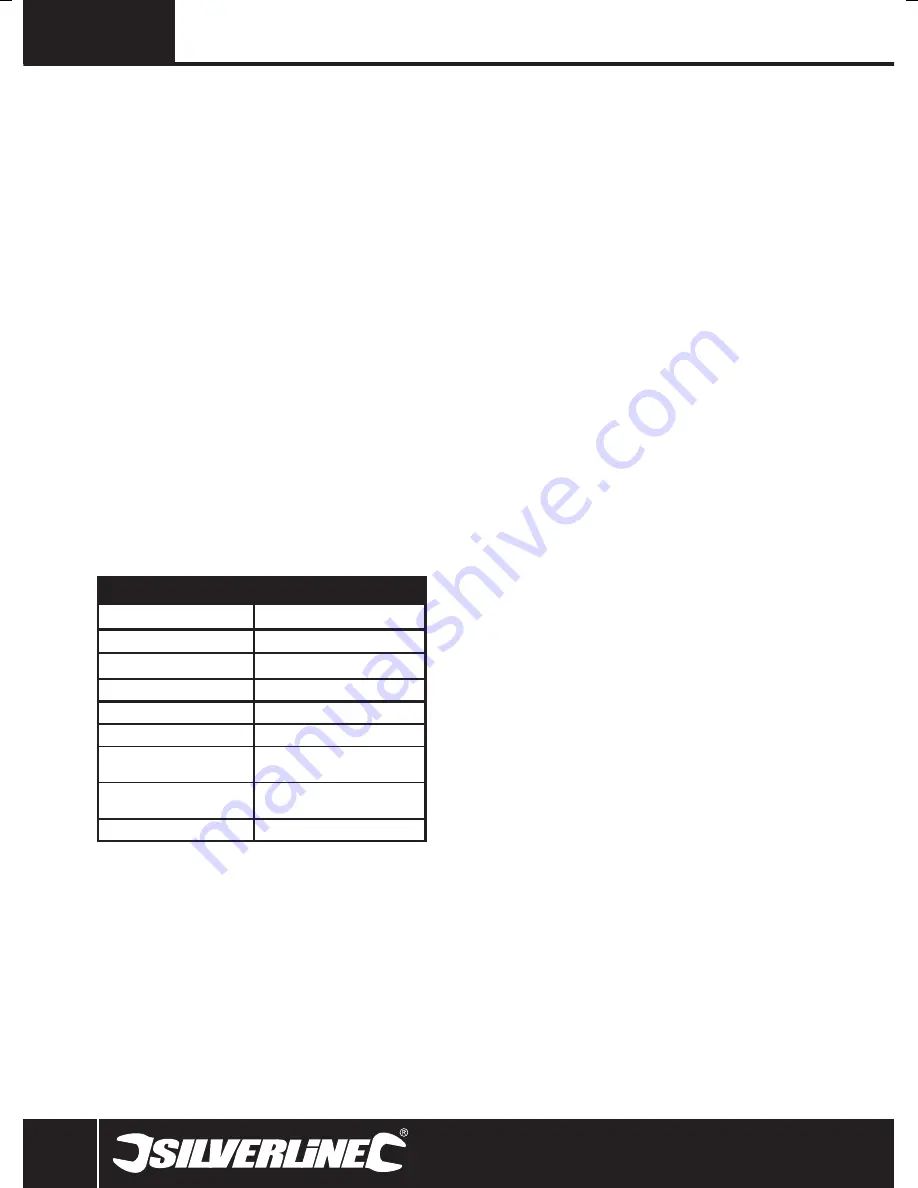

Viscosity table

Coating

Draining Time (secs)

Water-based paints*

20 - 40

Water-based primers

25 – 40

Water-based varnishes

20 – 35

Oil-based primers

25 – 40

Oil-based varnishes

15 – 40

Wood preservatives,

strippers, oils

use undiluted

Disinfectants, plant

protectants

use undiluted

Automobile spray paint

20 – 35

Before Use

Assembly

Attaching shoulder strap

• Attach Shoulder Strap (10) to the Shoulder Strap Mounts (5) on the Turbine

Unit (9)

Connect the air hose

• Push-fit the Air Hose (8) into the Air Outlet (7) on the Spray Machine (9) and Air

Inlet/Volume Regulator (3) on the Spray Gun (2)

• Insert air hose tightly to ensure a secure connection

Preparation of work area

• Cover all surfaces and objects that are not to be sprayed, or remove them from

the work area

• Silicate paint corrodes glass and ceramic surfaces upon contact. If you are

using silicate paint, ensure you completely cover all such surfaces

Paint preparation

WARNING

: This sprayer is not compatible with textured wall paints, latex paint,

caustic solutions, acidic coatings or paint or solutions containing granules or solids.

• Before use, most paints and other coatings need to be thinned (diluted) to the

proper viscosity for use with the Spray Gun (2):

1. Stir the paint thoroughly, then dip the Viscosity Test Cup (11) fully in the paint

2. Lift the Viscosity Test Cup out of the paint and measure the time in seconds

that it takes for the liquid to drain fully out of the cup

3. Refer to the viscosity table below for required draining times. If the coating

drains too slowly, it requires thinning

Note:

When mixing colours make a note of the mix quantities to ensure that

subsequent mixes are consistent with the first mix

• Dilute the paint in a separate container with suitable thinner or water until the

paint achieves the required draining time

• Only mix a small quantity of paint at a time

• Always recheck viscosity before refilling the Spray Gun

• If the feed rate of the paint is too low even at maximum flow setting, dilute in

steps of 5 – 10% until the feed rate meets requirements

Note:

The maximum viscosity of paint that can be used is 50din/sec but it is

recommended to keep to 40din/sec as shown in the chart above as the maximum

for general use.

798866_Z1MANPRO1.indd 6

04/07/2013 11:09