www.silverlinetools.com

7

500W HVLP Paint Sprayer

798866

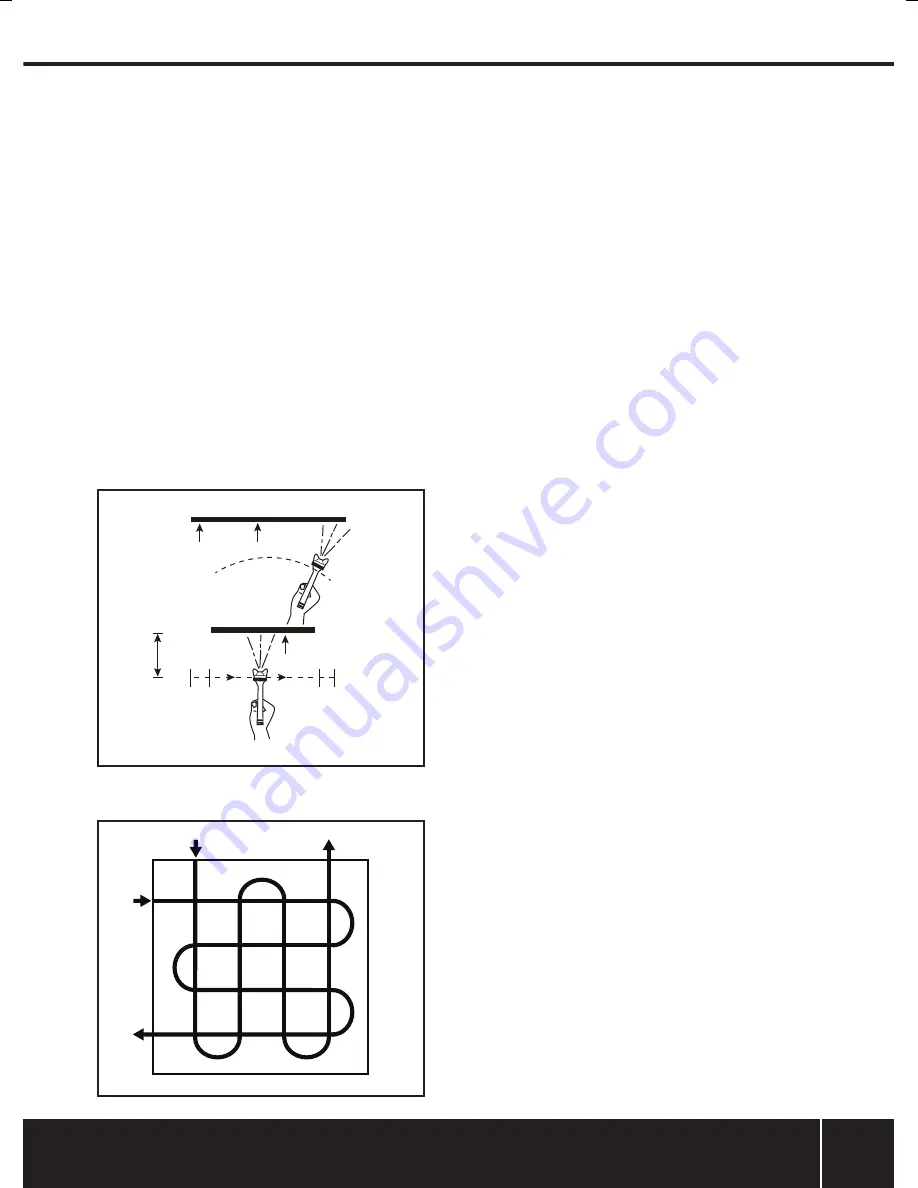

• Hold the Spray Gun so that the Air Cap (14) is 250 to 300mm from the surface

to be sprayed, depending on the required width of the spray jet

• Start the spray movement first, then squeeze the Trigger

Note:

The spray movement should come from the arm, not just the wrist. This

helps to maintain a uniform distance between Spray Gun and surface being

sprayed.

Note:

An uneven distance between Spray Gun and surface will result in uneven

paint application.

• Move the Spray Gun evenly across the surface and avoid interruptions. See

Fig. A below.

Note:

An even movement of the Spray Gun will achieve an even surface quality.

• If coating material builds up on the Nozzle (16) and Air Cap, cease spraying,

turn off power, disassemble and clean both parts with solvent or water as

appropriate

• Clean Spray Gun thoroughly as soon as you have finished spraying

Tips

• The most effective way to spray a vertical surface is to use a ‘cross-coat’

method, spraying in a zigzag pattern first in horizontal bands, then in vertical

bands. Use a flowing, serpentine motion as opposed to stopping and starting.

See Fig. B below.

• Move a flat section of cardboard parallel to the paint jet to mask edges

• When using strong colour shades, or painting over strong shades with a lighter

colour, apply at least two coats, allowing each coat to dry before applying the

next. This will ensure good coverage

• You can also use a cut-out stencil technique to paint shapes on the wall

WARNING:

Immediately after use the Spray Gun must be cleaned to prevent paint

drying within the Spray Gun. If you wish to mix or dilute another batch of paint

only do so without cleaning if there is no risk of the paint drying.

Coating will be

light at this point

Start

stroke

Pull

trigger

Release

trigger

End of

Stroke

Coating will be

heavy at this point

Correct

Wrong

Coating should be even

and wet when spraying

200-250mm

Maintenance

Cleaning

Note:

It is essential that this spray equipment is cleaned thoroughly after each

use in order to maintain trouble-free operation. Failure to clean and maintain your

equipment in accordance with advice below may invalidate your guarantee.

Always ensure that the machine is disconnected from the mains power supply

before performing any maintenance procedures

After each use:

1. Switch off the Turbine Unit (9)

2. Unscrew Paint Container (12) and empty container of any residue of coating

material

3. Pre-clean the Paint Container and feed tube with suitable solvent or warm

water and a soft brush

4. Fill the Paint Container with warm water (or suitable solvent) and reassemble

Spray Gun (2)

5. Switch on the machine and spray the water (or solvent) into a container

or cloth

6. Repeat the above procedure until the liquid being sprayed is clear

7. Switch off the machine

8. Empty the Paint Container completely. Always keep the container seal free of

any residue of coating material and check for any damage

9. Unscrew the Nozzle Assembly Cap (1) and remove the Air Cap (14) and

Nozzle (16)

10. Clean Air Cap and Nozzle thoroughly with suitable solvent or warm water

and a soft brush.

WARNING:

Never use a sharp metal object to clean the nozzle or air holes

11. Clean the exterior of the Spray Gun and Paint Container with a cloth soaked

in solvent or water

Air filter

• Check the air filter in the Air Filter Compartment (4) periodically and replace if

dirty or clogged

WARNING:

Never operate the wall sprayer without the air filter in place; dirt could

be sucked in and damage the motor

Disposal

Always adhere to national regulations when disposing of power tools that are no

longer functional and are not viable for repair.

• Do not dispose of power tools, or other waste electrical and electronic

equipment (WEEE), with household waste

• Contact your local waste disposal authority for information on the correct way

to dispose of power tools

Fig. A

Fig. B

798866_Z1MANPRO1.indd 7

04/07/2013 11:09