PerformaxIQEasyEx_UM_9752153510_NL_D_GB_FR_V1_4

85

GB

6.4.2 Operation mode CLFB (Closed Loop FeedBack) with Sensor IQ Easy

First the Sensor IQ Easy must be paired with the Performax Ionisation bar.

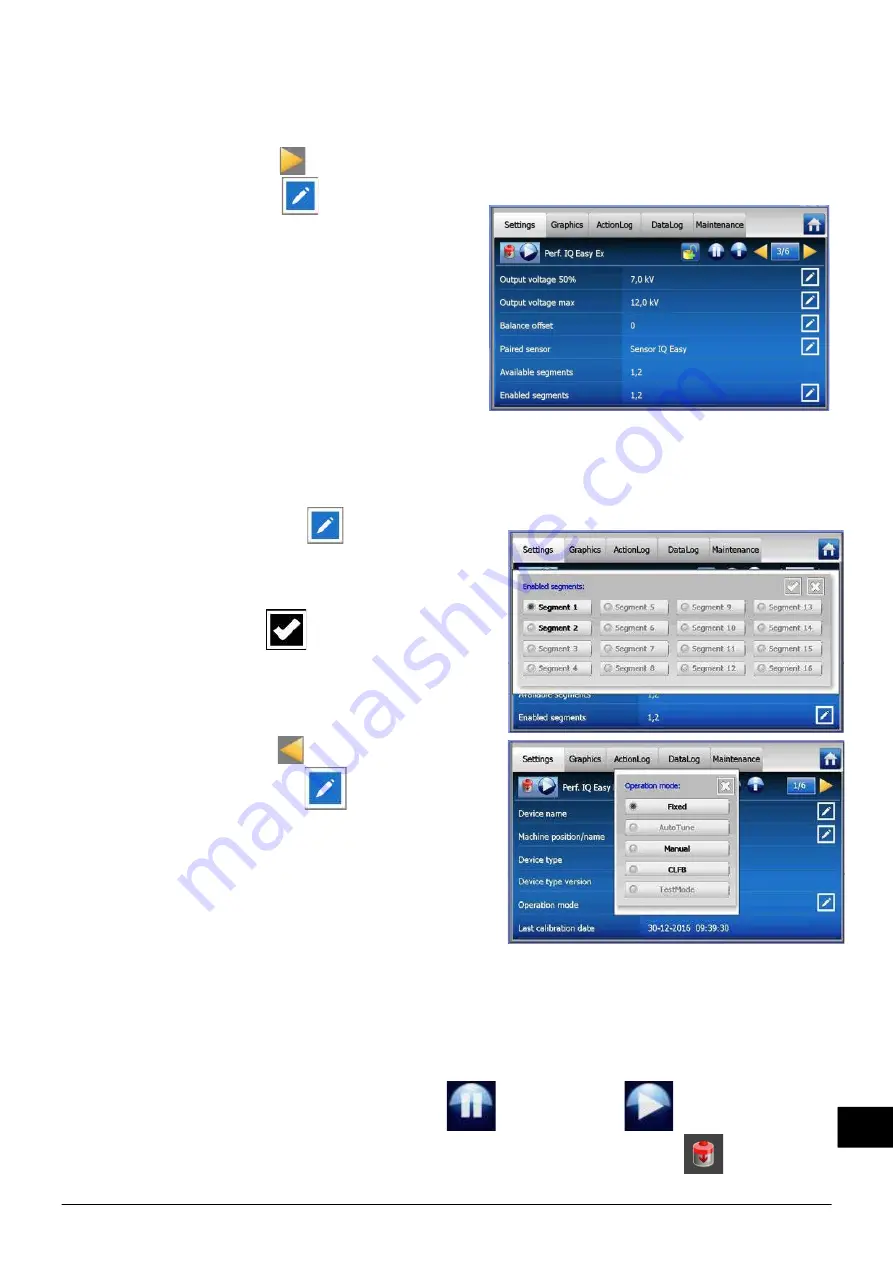

Go with the following page

symbol to the parameter

Paired

sensor.

-

Click

Paired sensor

- Select the IQ Easy sensor which will provide

the measurement values for the anti-static bar

- With several sensor segments in operation, an individual sensor segment can be switched

off. This may be necessary in case you are using a smaller film and hence a segment of the

sensor will be outside of the area of the film. The anti-static bar will then calculate using the

average measurement values of the active (enabled) segments

- To disable a segment, click

Enabled segments

.

- Select the segments to be disabled

- Confirm selection with

Go with the previous page

symbol to the

parameter

Operation

mode

- Select CLFB

The sensor bar should now be connected to the

Performax IQ Easy Ex bar.

The anti-static bar will now use the average (avg)

of the enabled segments to regulate ionization.

6.5 Anti-static bar Standby & Active and Autorun setting.

By default, the bar will become active once the Manager has gathered all the information,

because the autorun parameter has been set to

yes

.

On each tab, you can set the device to Standby

or active mode

The status is indicated in the left upper corner by means of a color behind the

symbol: