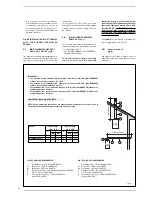

– If the terminal discharges into a pathway or passageway

check that combustion products will not cause nuisance and

that the terminal will not obstruct the passageway.

– Where the lowest part of the terminal is fitted less than 2 m

(78 in) above ground, above a balcony or above a flat roof to

which people have access, the terminal MUST be protected

by a purpose designed guard.

– Where the terminal is fitted within 850 mm (34 in) of a plas-

tic or painted gutter, or 450 mm (18 in) of painted eaves, an

aluminium shield at least 1,500 mm (59 in) long must be fit-

ted to the underside of the painted surface.

– The air inlet/outlet flue duct MUST NOT be closer than 10

mm (0.4 in) to combustible material.

– In certain weather conditions the terminal may emit a plume

of steam. This is normal but positions where this would

cause a nuisance should be avoided.

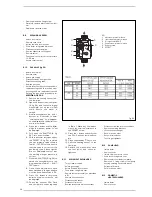

Terminal position

Minimum spacing

A

Directly below an openable window, air vent

or any other ventilation opening

300 mm

12 in

B

Below guttering, drain pipes or soil pipes (*)

75 mm

3 in

C/D

Below eaves, balconies or carport roof

200 mm

8 in

E

From vertical drain pipes or soil pipes

75 mm

3 in

F

From internal or external corners

300 mm

12 in

G

Above adjacent ground, roof or balcony level

300 mm

12 in

H

From a boundary or surface facing the boiler

600 mm

24 in

I

From a terminal facing the terminal

1,200 mm

48 in

J

From an opening in the carport

(eg door, window into dwelling)

1,200 mm

48 in

K

Vertically from a terminal on the same wall

1,500 mm 60 in

L

Horizontally from a terminal on the same wall

300 mm 12 in

M

Horizontally from a vertical terminal to a wall

300 mm 12 in

N

Horizontally from an openable window or other opening 300 mm 12 in

P

Above an openable window or other opening

300 mm

12 in

Q

From an adjacent vertical terminal

600 mm

24 in

(*) For condensing boilers this distance can be reduced to 25 mm without effecting boiler per-

formance, but it will be necessary to protect the surfaces from the effects of condensate

TABLE 4

Fig. 9

14

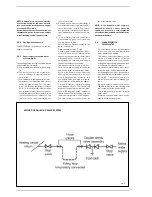

2.9.1

Climatic control option

The boiler is designed for connection to an

external temperature sensor, supplied on

request (code 8094101) in conjunction

with remote control (code 8092226),

which can automatically regulate the tem-

perature value of the boiler output accor-

ding to the external temperature.

For installation, follow the instruction in the

package. Expansion control kit 8092240

will also be required.

2.9.2 External

wired

controls

The heating function of the boiler can be

controlled by voltage free signal, TA, con-

nected to terminals 5 & 6 after removal of

the link.

2.9.3

Use with

different

electronic

systems

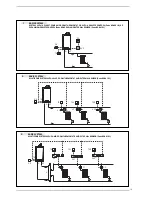

Some examples are given below of boiler

systems combined with different electronic

systems.

Where necessary, the parameters to be

set in the boiler are given.

The electrical connections to the boiler

refer to the wording on the diagrams (fig.

11). Zone valve control is activated with

every heating request from remote con-

trol.

Description of the letters indicating the

components shown on the system dia-

grams 1 to 3:

M

C.H. flow

R

C.H. return

CR

Remote control CR 63

SE

External temperature sensor

TA 1-2

Zone room thermostat

VZ 1-2 Zone valve

RL 1-2 Zone relay

Sl

Hydraulic separator

P 1-2

Zone pump

EXP

Expansion card

(code 8092240)

For guidance only, flues should be installed in accordance with BS5440