28

– Remove electrode fixing screw

– Carefully remove electrode from bur-

ner

– Replace in reverse order.

6.9 EXPANSION

VESSEL

– Isolate from mains

– Remove case cover

– Isolate flow and return valves

– Drain boiler using fitted drain vent

– Disconnect expansion pipe

– Remove expansion securing nut

– Remove vessel

– Check new vessel for correct pressure

1-1.25 bar

– Refit in reverse order

6.10

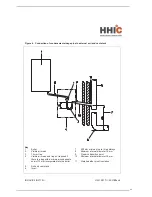

GAS VALVE (fig. 24)

– Isolate from mains

– Remove cover

– Isolate gas supply

– Disconnect leads from gas valve

– Disconnect sensing tube

– Remove gas valve

– Refit in reverse order ensuring seals are

replaced as required fit in reverse order

ensuring seals are replaced as required

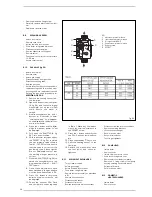

– Setting the gas valve procedure for

MERIDIAN HE 30 C

:

1. Remove the heating sensor from

the flow pipe.

2. Open the downstream test point

(4 fig. 24) and connect a digital

manometer set on the mmH

2

0

scale. Ensure the meter is

zeroed.

3. Simultaneously press the - and +

buttons for 5 seconds to enter

“chimney sweep”. “Lo” will appear

on the display and the boiler runs

at minimum power.

4. Press the + button and the boiler

will go to maximum power “Hi” will

be displayed.

5. Fully open the SHUTTER (5 fig.

24) - turn anti clockwise.

6. With the shutter fully open, adjust

the OFF-SET (6 fig. 24) to obtain

the first pressure value shown in

Table 1 - OFF-SET column, ensure

that the value is correct for the

gas being used. If these figures

are not obtainable, confirm that

the working inlet gas pressure is

correct.

7. Close the SHUTTER (5 fig. 24) to

obtain the second pressure rea-

ding indicated in Table 1 – SHUT-

TER column.

8. Once these adjustments have

been obtained, a flue gas analysis

must be done. See section 4.2.2.

9. Press the - button to return the

boiler to minimum output “Lo” will

be displayed.

10. Check the analyzer CO

2

/Ratio

and compare to values reported

in Table 1. Make any final adjust-

ments by small adjustments to

the OFF-SET screw.

11. Press the + button and verify that

the CO

2

/Ratio has remained sta-

ble.

12. Press the Standby

key to exit.

13. Refit the heating sensor to the

flow pipe.

14. Remove the manometer, close

the test point, and check for

tightness.

6.11

MAIN HEAT EXCHANGER

– Turn off power supply

– Isolate gas supply

– Isolate flow and return valves

– Drain boiler using drain vent

– Remove burner assembly as described

in 6.1

– Remove flue connection

– Disconnect flue sensor

– Disconnect limit stat

– Remove condensate drain connections

– Disconnect flow and return connections

– Remove two fixing brackets

– Lift out heat exchanger

– Refit in reverse order

– Recommission boiler

– Test for gas tightness.

6.12 PUMP

HEAD

– Isolate boiler

– Remove cover

– Isolate flow and return valves

– Drain boiler using drain vent

– Remove electrical lead from pump

– Remove 4 x fixing screws from pump

housing catching any excess water

– Pull pump forward

– Refit in reverse order

6.13 DOMESTIC

HEAT EXCHANGER

– Isolate boiler

– Remove cover

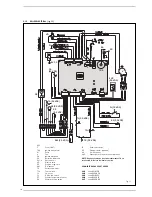

Fig. 24

KEY

1

Upstream pressure intake

2

Intermediate pressure intake

3

Air signal inlet (VENT)

4

Downstream pressure intake

5

Capacity step

6

OFF-SET

1

2

3

4

5

6